Injection mold for motor wind wheel

A technology for injection molds and wind wheels, applied in the field of injection molds for motor wind wheels, which can solve the problems of affecting molding quality, inability to cool uniformly, and slow cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

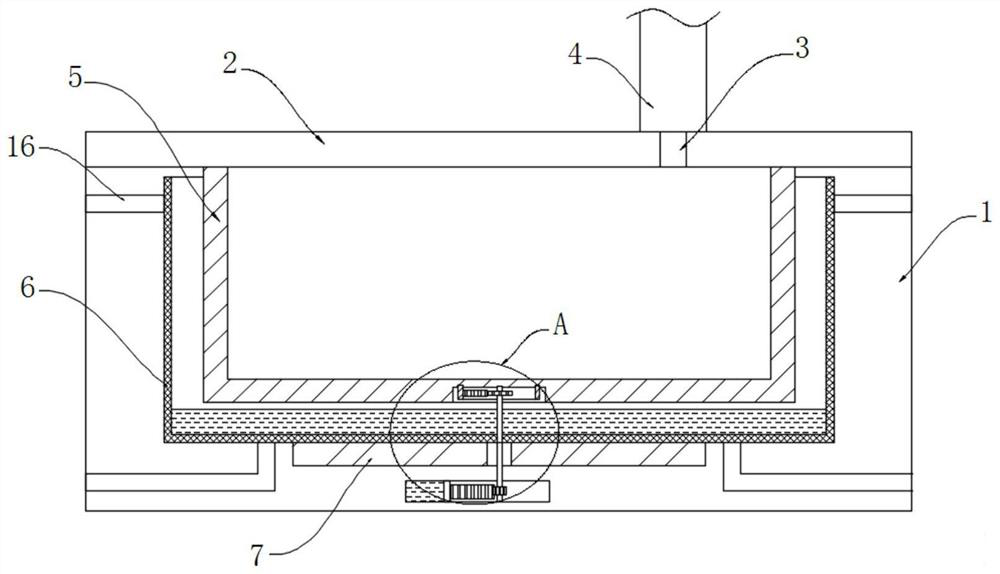

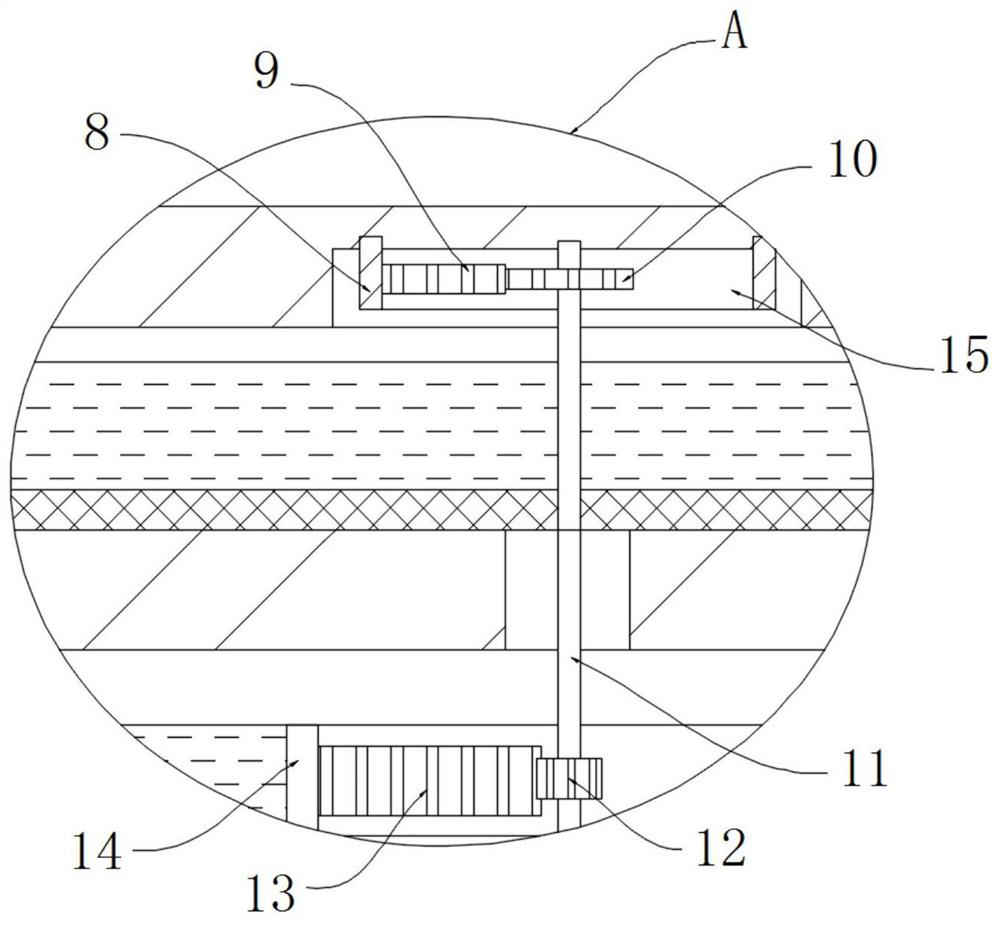

[0020] refer to Figure 1-2 , an injection mold for a motor wind wheel, comprising an outer box 1, a case cover 2 and an injection port 3, the injection port 3 is sealed and connected with an injection cavity 4, a mold cavity is opened in the outer box 1 and the outside of the mold cavity A mold cavity cover 5 is sealed and connected, and the outer box 1 is provided with a cooling cavity outside the cavity cover 5, and a cooling jacket 6 is sealingly connected to the outside of the cooling cavity, and the cooling jacket 6 is equipped with a magnetized liquid. The bottom of the sleeve 6 is fixedly connected with a permanent magnet 7, and the mold cavity sleeve 5 and the cooling sleeve 6 are jointly connected with a transmission structure;

[0021] The transmission structure includes a groove 15 provided at the bottom of the mold cavity cover 5, the bottom of the groove 15 is fixedly connected with an internal gear 8, the internal gear 8 is meshed with a planetary gear 9 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com