Preparation process of light composite structure toughened glass

A technology of tempered glass and composite structure, applied in glass/slag layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of material damage, poor toughness, poor flame retardant effect, etc., to improve toughness , Improve heat resistance and flame retardant ability, improve the effect of anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

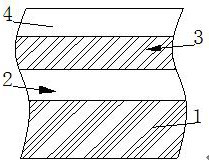

[0032] see Figure 1-3 , the present invention provides the following technical solutions: a light composite structural tempered glass, comprising a tempered glass body 1, the surface of the tempered glass body 1 is fixedly bonded with a tough layer 2, and the surface of the tough layer 2 is fixedly bonded with an anti-corrosion layer 3.

[0033] Specifically, the tempered glass main body 1 includes the following raw materials in parts by weight: 100 parts of cullet, 20 parts of quartz sand, 6 parts of glass powder, 1 part of preservative, 3 parts of defoamer, 6 parts of adhesive, organic 6 parts of silane colloid, 3 parts of plasticizer, 1 part of waterproofing agent, 3 parts of flame retardant synergist.

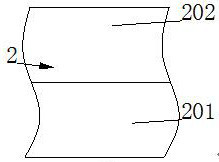

[0034] Specifically, the toughness layer 2 includes a polyurethane layer 201, and the surface of the polyurethane layer 201 is fixedly bonded with a silicone layer 202.

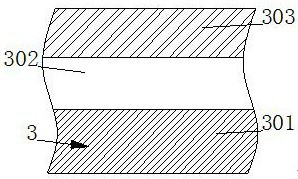

[0035] Specifically, the anticorrosion layer 3 includes an epoxy resin film 301, the surface of the e...

Embodiment 2

[0048] see Figure 1-3 , the present invention provides the following technical solutions: a light composite structural tempered glass, comprising a tempered glass body 1, the surface of the tempered glass body 1 is fixedly bonded with a tough layer 2, and the surface of the tough layer 2 is fixedly bonded with an anti-corrosion layer 3.

[0049] Specifically, the tempered glass main body 1 includes the following raw materials in parts by weight: 200 parts of cullet, 40 parts of quartz sand, 8 parts of glass powder, 2 parts of preservative, 4 parts of defoaming agent, 8 parts of adhesive, organic 8 parts of silane colloid, 4 parts of plasticizer, 2 parts of waterproofing agent, 4 parts of flame retardant synergist.

[0050] Specifically, the toughness layer 2 includes a polyurethane layer 201, and the surface of the polyurethane layer 201 is fixedly bonded with a silicone layer 202.

[0051] Specifically, the anticorrosion layer 3 includes an epoxy resin film 301, the surface...

Embodiment 3

[0064] see Figure 1-3 , the present invention provides the following technical solutions: a light composite structural tempered glass, comprising a tempered glass body 1, the surface of the tempered glass body 1 is fixedly bonded with a tough layer 2, and the surface of the tough layer 2 is fixedly bonded with an anti-corrosion layer 3.

[0065] Specifically, the tempered glass main body 1 includes the following raw materials in parts by weight: 300 parts of cullet, 60 parts of quartz sand, 10 parts of glass powder, 3 parts of preservative, 5 parts of defoamer, 10 parts of adhesive, organic 10 parts of silane colloid, 3-6 parts of plasticizer, 3 parts of waterproofing agent, 5 parts of flame retardant synergist.

[0066] Specifically, the toughness layer 2 includes a polyurethane layer 201, and the surface of the polyurethane layer 201 is fixedly bonded with a silicone layer 202.

[0067] Specifically, the anticorrosion layer 3 includes an epoxy resin film 301, the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com