Patents

Literature

34results about How to "Improve heat resistance and flame retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength wear-resistant tear-resistant rubber material

ActiveCN104086839AGood anti-scorch performanceImprove securityRubber materialEnvironmental resistance

The invention discloses a high-strength wear-resistant tear-resistant rubber material which is prepared from the following raw materials in parts by weight: 40-50 parts of carboxy nitrile rubber, 20-30 parts of chloroprene rubber, 10-18 parts of natural rubber, 12-20 parts of ethylene-octylene copolymer, 5-13 parts of silane coupling agent, 1.5-2 parts of sulfur, 2-4 parts of magnesium oxide, 2-5 parts of zinc oxide, 2.5-4 parts of environment-friendly flame retardant FR-T801, 1-2 parts of antimony trioxide, 20-30 parts of carbon microsphere, 5-15 parts of nano carbon black, 20-30 parts of modified kaolin, 1-2 parts of CPE special-type stabilizer, 1.5-3 parts of stearic acid, 5-7 parts of trioctyl trimellitate and 0.5-1.5 parts of paraffin. The rubber material has the advantages of excellent wear resistance, excellent tear resistance, high strength and high toughness.

Owner:宁国日格美橡塑股份有限公司

Flame-retardant acrylic coating

InactiveCN104356804ASuppress generationGood weather resistanceFireproof paintsAntifouling/underwater paintsAcrylic resinAcrylic coating

The invention discloses a flame-retardant acrylic coating. The flame-retardant acrylic coating is prepared from the following raw materials in parts by weight: 50-60 parts of water-soluble acrylic resin, 12-15 parts of terpene resin, 8-11 parts of alkyd resin, 3-6 parts of polyoxyethylene laurate, 2.3-2.6 parts of hydroxymethyl cellulose, 11-14 parts of attapulgite, 9-12 parts of zeolite powder, 1-2 parts of precipitated barium sulfate, 2-3 parts of melamine, 8-9 parts of zinc borate, 10-15 parts of methylated amino resin, 4-5 parts of aluminum oleate, 0.4-0.6 part of an epoxy-silane coupling agent, 15-25 parts of a pigment, 2.1-2.4 parts of a flexibilizer, 0.5-0.8 part of a defoamer, 0.7-1 part of a smoothing agent, 0.4-0.5 part of a mildew preventive, and 50-55 parts of a solvent. The flame-retardant acrylic coating disclosed by the invention is not only excellent in flame retardant property, and but also high in curing speed.

Owner:ANHUI JINDUN PAINT

High-performance environment-friendly cable sheath material

InactiveCN104194136AIncrease the degree of cross-linkingReduce gapInsulated cablesInsulated conductorsCarvacryl acetateChlorinated paraffins

The invention discloses a high-performance environment-friendly cable sheath material which comprises the following raw materials in parts by weight: 18-22 parts of ethylene-vinyl acetate resin, 8-15 parts of nitrile rubber, 20-40 parts of carbon black, 5-6 parts of light calcium carbonate, 7-8 parts of titanium dioxide, 0.5-1.5 parts of ammonium polyphosphate, 2-2.5 parts of magnesium oxide, 1-2 parts of zinc oxide, 20-30 parts of magnesium hydrate, 5-10 parts of zinc borate, 0.6-0.9 part of chlorinated paraffin, 1-2 parts of an antiager NBC, 1-1.5 parts of pentaerythritol aliphatic ester, 1-1.5 parts of citrate, 1-1.5 parts of sulphur and 1.5-2 parts of an accelerant TMTD. The high-performance environment-friendly cable sheath material disclosed by the invention has excellent oil resistance property and excellent heat and flame resistance property and also has excellent wear resistance and wear resistance.

Owner:ANHUI MENTOR CABLE GROUP

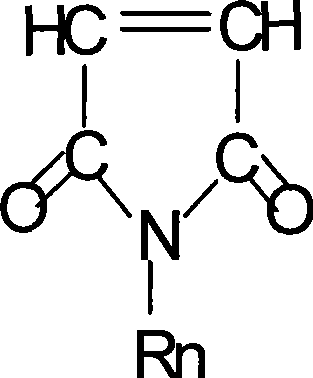

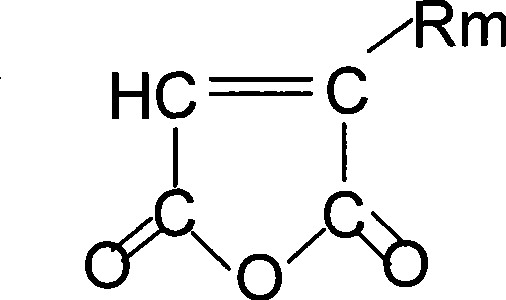

Method for synthesizing heat resisting flame-retarded resin emulsion

A synthetic method of a heat-resistant flame-retardant resin emulsion comprises the following steps: adding primary emulsion (a) formed by a small amount of monomers, an emulsifying agent and an initiator to a reactor, then heating to 30-100 DEG C for a certain time, and respectively and continuously or periodically and intermittently adding a monomer solution (b) with homogeneous phase and emulsion (c) of the emulsifying agent to the reactor to be mixed with the primary emulsion (a) for polymerization. The synthetic method can help obtain polymer emulsion with high conversion ratio and wide adjustment range of copolymer structure and composition, easily control reaction and obtain the product with high heat resistance and good flame retardance. The prepared heat-resistant flame-retardant resin emulsion has uniform structure, high heat resistance and good flame retardance, and very ideal yield and stability, can be widely used for modifying the heat resistance and the flame retardance of such materials as ABS, PC, PBT and the like, or can be used alone for preparing high heat-resistant parts of automobiles and household electrical appliances.

Owner:PETROCHINA CO LTD

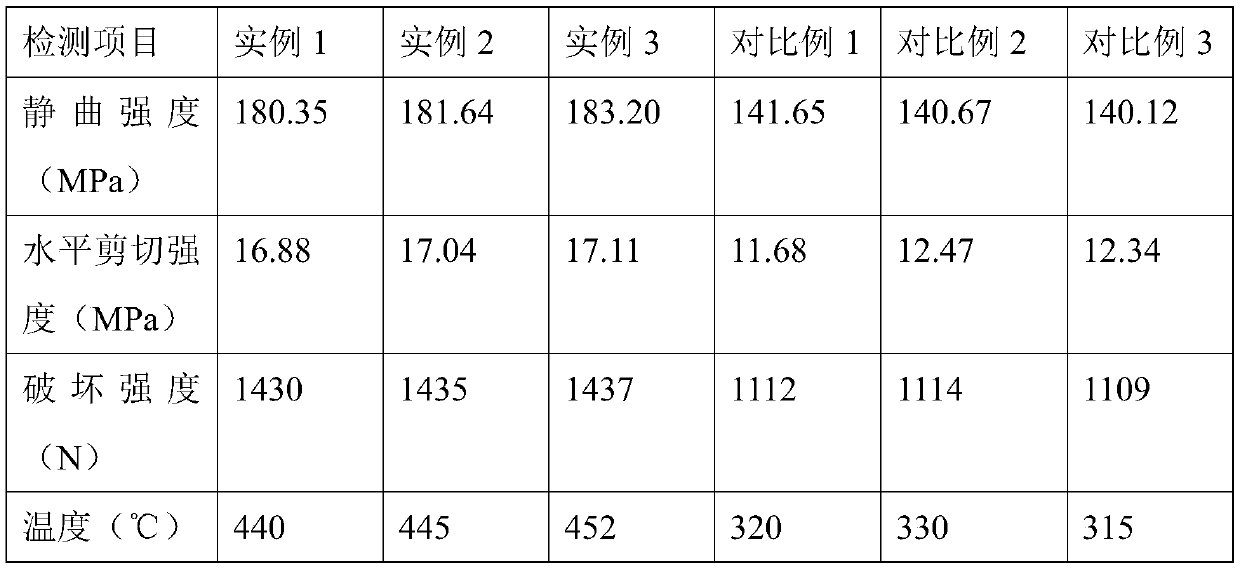

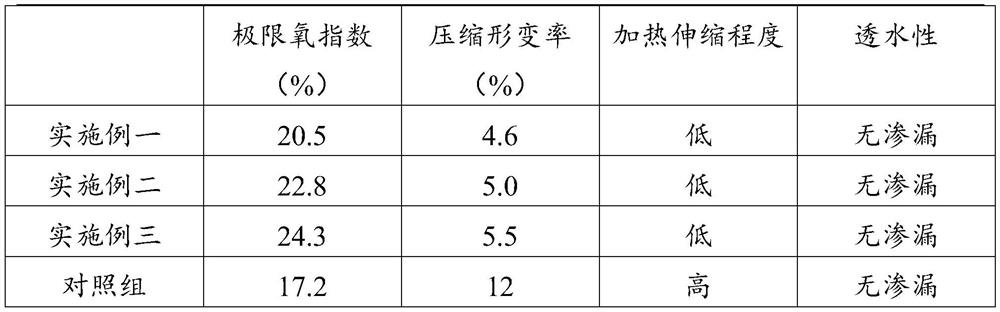

Nanoceramics-reinforced high-precision PVC-NBR composite foaming board and preparation method thereof

InactiveCN106117913AHigh dimensional accuracyImprove heat resistance and flame retardancyGreen environmentMicrosphere

The invention discloses a high-precision PVC‑NBR composite foam board reinforced by nano-ceramic. Improve the dimensional accuracy of the composite board and prevent the board from being deformed by heat. The added nano-ceramic powder is modified by a silane coupling agent to better disperse and bind, and the effect of strengthening and toughening is remarkable, which effectively improves the heat resistance and flame retardancy of the composite board. , more safe and reliable, the composite foam board finally prepared by the present invention has outstanding advantages in terms of thermal stability, flame retardant safety, environmental protection, shape stability, etc., and has a good application prospect.

Owner:CHUZHOU HONGYUAN SPRAYING

Heat-resistant and flame-retardant modified epoxy resin coating

InactiveCN104449219AInhibitionEvenly dispersedFireproof paintsPolyurea/polyurethane coatingsCalcium silicateEpoxy

The invention discloses a heat-resistant and flame-retardant modified epoxy resin coating comprising the following raw materials in parts by weight: 55-58 parts of epoxy resin, 20-23 parts of polyurethane resin, 24-27 parts of alkyd resin, 3-5 parts of hollow glass beads, 13-16 parts of active calcium silicate, 3-4 parts of fumed silica, 7-10 parts of mica powder, 14-17 parts of modified yttrium oxide, 2.1-2.4 parts of calcium stearate, 2.2-2.5 parts of diethyl phthalate, 7-9 parts of 1.5 hydrated zinc borate, 8-11 parts of melamine, 4-7 parts of a drier, 20-24 parts of pigment, 1.9-2.2 parts of a toughening agent, 0.7-1 part of a defoaming agent, 1.2-1.5 parts of a leveling agent and 1-2 parts of a mildew preventive. The heat-resistant and flame-retardant modified epoxy resin provided by the invention has excellent heat resistance and flame retardance, high curing speed and low curing conditions.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Preparation process of 3D printing metal powder

InactiveCN107999776AIncreased shear strengthImprove adhesionAdditive manufacturing apparatusTransportation and packagingOxidation resistantAlloy

The invention discloses a preparation process of 3D printing metal powder, and relates to the technical field of 3D printing powder. The preparation process of the 3D printing metal powder comprises the steps of (1) mixed material pretreatment, (2) smelting, (3) metal powder slurry preparation, (4) air blowing atomization and (5) collection. According to the preparation process of the 3D printingmetal powder, mixed powder of copper powder, nickel powder and tin powder is adopted as a matrix, the use quantity and the size are strictly controlled, and no influence is generated on overall flowability of alloy powder; the purity and quality of a smelted alloy can be improved through high-temperature refining of a multi-component refining agent; the heat resistance, flame retardance and oxidation resistance of the alloy powder are improved through an organic bond; and in the air blowing atomization process, helium serves as subsequent atomization power, the metal size is enlarged fast, theparticle size of atomized metal particles is smaller, the degree of sphericity is good, the crystal structure is more stable, and the particle size uniformity of the 3D printing metal powder is excellent.

Owner:马斌祥

Stretch-proof wear-resistant oil-resistant modified cable material and preparation method thereof

InactiveCN104231451AGood oil resistanceAccelerated corrosionRubber insulatorsVulcanizationWear resistant

The invention discloses a stretch-proof wear-resistant oil-resistant modified cable material which is prepared from the following raw materials in parts by weight: 8-12 parts of chloroprene rubber, 25-28 parts of hydrogenated butadiene-acrylonitrile rubber, 70-73 parts of an ethylene propylene diene monomer, 17-20 parts of melamine formaldehyde resin, 13-16 parts of pre-treated plant powder, 8-11 parts of aluminum borate crystal whiskers, 2-5 parts of titanium nitride, 4-8 parts of aluminum oxide, 27-30 parts of calcite, 24-27 parts of furnace black, 18-21 parts of quartz powder, 6-8 parts of diethyl phthalate DEP, 3-4 parts of cresyl diphenyl phosphate CDPP, 3.4-5.3 parts of antimonous oxide, 5.3-6.2 parts of red phosphorus capsules, 6-8 parts of a peroxide vulcanization system, 0.4-0.8 part of an antiager D-50 and 1.2-1.8 parts of an antiager SP. The invention further discloses a preparation method of the stretch-proof wear-resistant modified cable material.

Owner:ANHUI LAND GRP

Flame-retardant wear-resisting modified acrylic resin coating

InactiveCN104449136AInhibitionEvenly dispersedFireproof paintsPolyurea/polyurethane coatingsEpoxyAcrylic resin

The invention discloses a flame-retardant wear-resisting modified acrylic resin coating which comprises the following raw materials in parts by weight: 68-71 parts of acrylic resin, 12-15 parts of polyurethane resin, 16-19 parts of aldehyde ketone resin, 7-10 parts of powdery ethylene propylene diene monomer, 6-9 parts of hollow glass beads, 5-7 parts of organic bentonite, 3-5 parts of talcum powder, 7-9 parts of zeolite powder, 12-15 parts of modified yttrium oxide, 5-7 parts of mica powder, 2.5-3 parts of diisononyl phthalate, 5-8 parts of epoxy xanthium sibiricum butyl oleate, 3-6 parts of sodium laurate, 3-5 parts of (1,3-dichloro-2-propyl) phosphotriester, 13-16 parts of nano-magnesium hydroxide, 4-6 parts of antimony trioxide, 8-11 parts of a drying catalyst, 12-15 parts of a pigment, 3-4 parts of a toughening agent, 1.5-2 parts of an antifoaming agent, 2-3 parts of a leveling agent and 1-2 parts of a mould inhibitor. The flame-retardant wear-resisting modified acrylic resin coating has excellent flame retardancy and wear resistance and high curing speed.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Fireproof coal ash heat insulation material and preparation method thereof

The invention discloses a fireproof coal ash heat insulation material which comprises, by weight, 15-25 parts of compressed coal ash, 20-40 parts of acidified coal ash, 10-14 parts of water glass, 12-18 parts of adsorption filling soil, 5-7 parts of coupling agents, 15-25 parts of adhesives, 9-13 parts of glass beads, 8-16 parts of reinforced fibers and 7-11 parts of flame-retardant additives. The coal ash is comprehensively recycled, resources are saved, environments are protected, waste is sufficiently used, the prepared heat insulation material is low in specific gravity, high in strength, good in heat insulation performance, excellent in high-temperature resistance and flame resistance and good in stability. Besides, the preparation method is low in material cost and simple and clear in process and has a high practical value and a good application prospect, and raw materials are easily obtained.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Hybridized melamine-formaldehyde silicon aerogel modified flame-retardant polypropylene foaming plate and preparation method thereof

InactiveCN106750940APromote environmental protectionImprove the defect of poor affinityPolymer scienceHeat stability

The invention discloses a hybridized melamine-formaldehyde silicon aerogel modified flame-retardant polypropylene foaming plate and a preparation method thereof. The foaming material is good in toughness and better heat stability, and melt strength is improved; hybridized melamine-formaldehyde silicon aerogel added has a unique nano-porous structure and can be absorbed in a resin melt during foaming, melt strength can be further improved, heat-resisting and flame-retardant performances of resin can be effectively improved, good synergistic effect of hybridized aerogel on a flame retardant in the system can be achieved, and use amount of the flame retardant is effectively controlled; the prepared polypropylene foaming plate is good in environment protection property, high in foaming rate, lightweight and heat insulating, hydrophobic and corrosion resisting and economic and durable, and use scope of a traditional polypropylene foaming material is greatly widened.

Owner:阜阳市三郁包装材料有限公司

Sound absorption plate and preparation method thereof

The invention discloses a sound absorption plate and a preparation method thereof. The sound absorption plate is prepared from the following raw materials in parts by weight: 30 to 50 parts of gypsum powder, 20 to 30 parts of bamboo carbon fiber, 8 to 15 parts of glass fiber, 1 to 5 parts of attapulgite clay, 5 to 10 parts of blast furnace slag, 1 to 3 parts of magnesium oxide, 0.6 to 2.8 parts of an inorganic adhesive, 0.5 to 1.6 parts of a water repellent and 0.2 to 0.8 part of a flame retardant. The preparation method of the sound absorption plate comprises the steps of purification of the attapulgite clay, preparation of a substrate material, preparation of a molding blank and natural maintenance. The components of the sound absorption plate are safe and environment-friendly, and the sound absorption plate is good in waterproofing and flame retardancy effect and can isolate sound and heat; the intensity and the hardness of a gypsum board are retained.

Owner:合肥慧林建材有限公司

High-flame-retardance and high-toughness expandable polystyrene

The invention discloses high-flame-retardance and high-toughness expandable polystyrene which comprises the following raw materials in parts by weight: 95-105 parts of styrene, 20-30 parts of ethylene-propylene-diene monomer rubber, 25-35 parts of polyethylene, 150-170 parts of water, 0.3-0.4 parts of dibenzoyl peroxide, 0.05-0.1 parts of tert-butyl peroxybenzoate, 0.2-0.3 parts of dicumyl peroxide, 2-5 parts of nano calcium silicate, 0.02-0.04 part of a silane coupling agent KH560, 2-4 parts of polyvinyl alcohol, 1-3 parts of cellulose ether, 2-8 parts of nekal, 0.05-0.15 parts of a defoamer, 0.2-0.5 parts of an antioxidant, 0.4-1.2 parts of a flame retardant and 7-12 parts of a foamer. The high-flame-retardance and high-toughness expandable polystyrene disclosed by the invention is excellent in flame-retardant and heat-resistant performance, good in toughness and excellent in impact resistance.

Owner:芜湖市京桥精密智造有限公司

External wall penal with excellent silencing and fireproof performances

InactiveCN105838231AImprove lipophilicityPromote softeningFireproof paintsCovering/liningsAntioxidantPotassium hydroxide

The invention discloses an exterior wall panel with excellent sound-absorbing and fire-proof performance, which comprises a base layer, a sound-absorbing fireproof layer, a plastering mortar layer, a waterproof layer, a decorative coating and a wear-resistant layer; the preparation method of the sound-absorbing fireproof layer is as follows: hydroquinone, Potassium hydroxide and toluene are mixed evenly, and then a toluene solution containing hexachlorocyclotriphosphazene is added dropwise, heated up, kept warm, washed with an alkali solution to obtain an organic phase, then the organic phase is distilled under reduced pressure, dried in vacuum, and recrystallized to obtain material a ; Mix material a and polytetrahydrofuran ether glycol evenly, then add trimethyl-1,6-hexamethylene diisocyanate, fill with dry nitrogen for protection, heat up, keep warm, and cool down to obtain material b; Add trimethylpentanediol, glycerin, bismuth neodecanoate, foaming agent, foaming aid, expanded perlite, palygorskite, diatomaceous earth, glass fiber, flax fiber, zinc borate hydrate, anti-aging agent and Acetone is mixed evenly, coated on the surface of the base layer, then heated up, and kept warm to obtain a sound-absorbing and fire-proof layer.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

Elastic flame-retardant EVA emulsion coated polypropylene-based nonwoven sound-absorbing material applied to automotive interiors

InactiveCN104611930ALarge specific surface areaImprove heat resistance and flame retardancyFibre treatmentNon-woven fabricsEmulsionRosin

The invention relates to a nonwoven sound-absorbing material, in particular to an elastic flame-retardant EVA emulsion coated polypropylene-based nonwoven sound-absorbing material applied to automotive interiors. The material is prepared from the following raw materials in parts by weight: 10-15 parts of poly-1-butene, 20-25 parts of 325-400-mesh expanded perlite, 2-3 parts of rosin, 5-8 parts of polycaprolactam, 0.5-0.8 part of a silane coupling agent, 20-24 parts of polypropylene, 12-15 parts of an EVA emulsion with the solid content of 10-12%, 0.5-0.8 part of nano spherical ferroferric oxide powder, 0.1-0.2 part of an anti-oxidant 168, 0.4-0.6 part of ammonium polyphosphate and 1-2 parts of an additive. The sound-absorbing material provided by the invention is high in raw material utilization rate, light, environment-friendly, flexible and compact, and free of pollution to the automotive interior environment; the sound-absorbing material is a novel and practical automotive sound-absorbing material.

Owner:安徽省中日农业环保科技有限公司

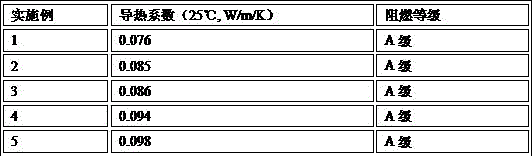

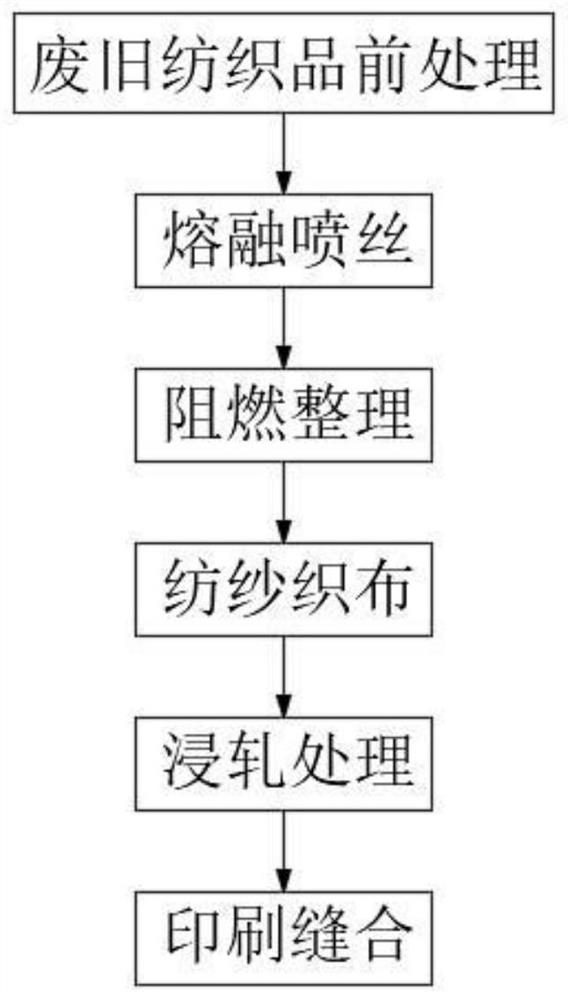

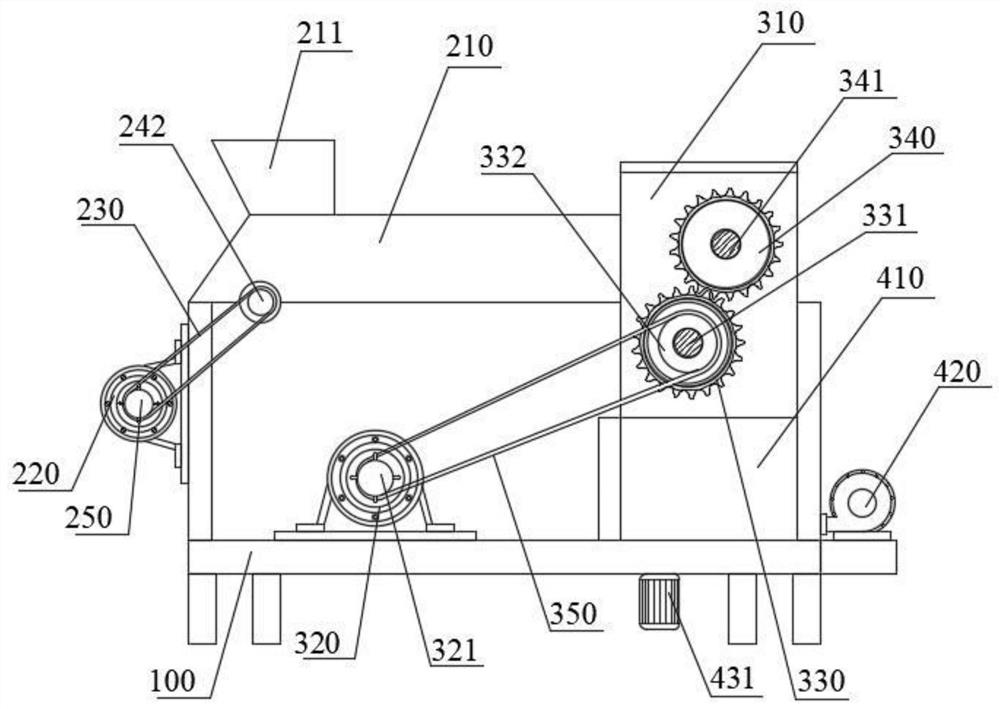

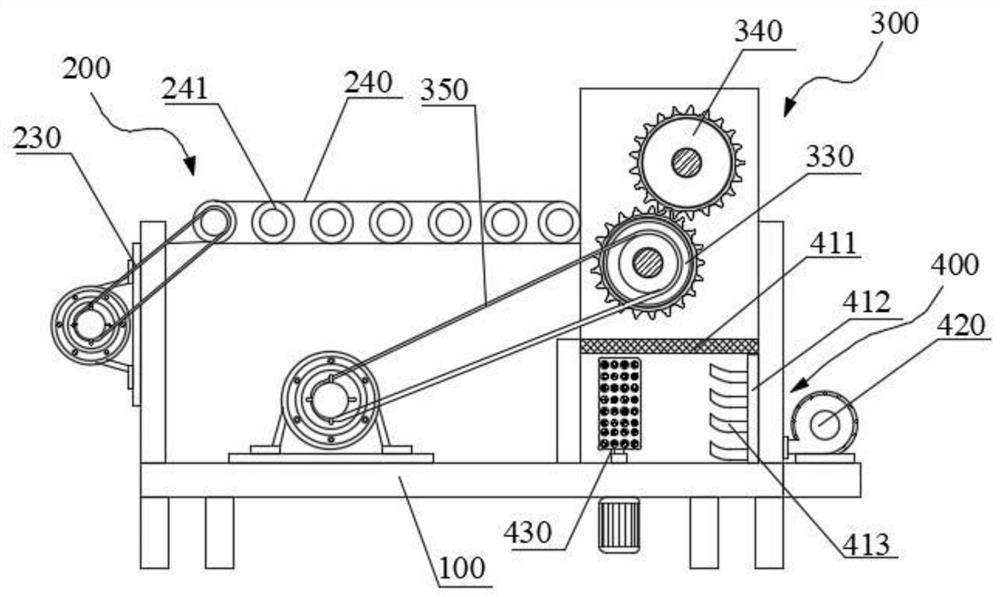

Production process for manufacturing flame-retardant canvas bag from waste textiles

PendingCN113914103AImprove cleanlinessImprove heat resistance and flame retardancyHeat resistant fibresWoven fabricsPolyesterPolymer science

The invention discloses a production process for manufacturing a flame-retardant canvas bag from waste textiles, and relates to the technical field of canvas bag manufacturing. The technological process comprises the steps of waste textile pretreatment, melt spinning, flame-retardant finishing, spinning and weaving, padding treatment, and printing and sewing. Continuous cutting, smashing and magnetic separation are carried out through cutting, smashing and magnetic separation integrated equipment to obtain polyester fiber short filaments which are fixed in specification, free of metal impurities and high in cleanliness, and then cleaning liquid dipping, filtering and drying are carried out through dipping, filtering and drying equipment to obtain separated fiber short filaments which are free of oily impurities and high in cleanliness; in the flame-retardant finishing and padding treatment procedures, a flame retardant and a dipping liquor both contain flame-retardant components, and regenerated fiber filaments and a canvas are subjected to flame-retardant finishing, so that the heat-resistant and flame-retardant performance of the canvas bag is improved; and the moisture absorption and air permeability performance, strength and heat-resistant and flame-retardant performance of the canvas bag are improved by adding cotton fibers and aramid fibers in the spinning and weaving procedure.

Owner:JIESHOU TIANZHU TEXTILE MATERIAL

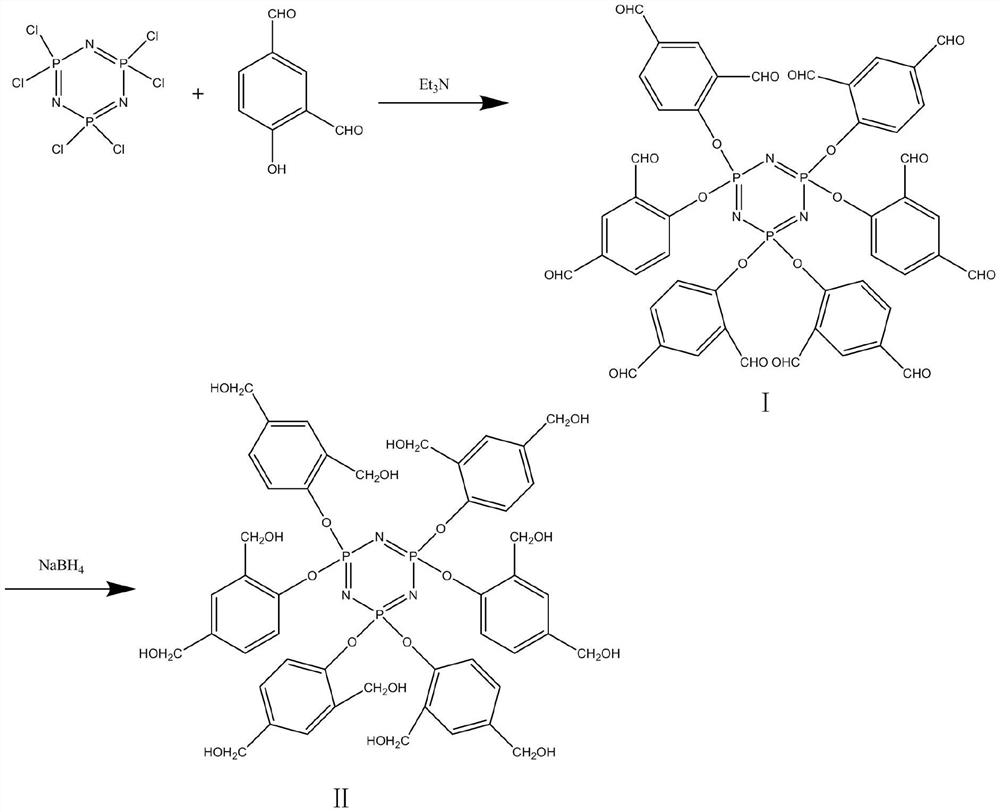

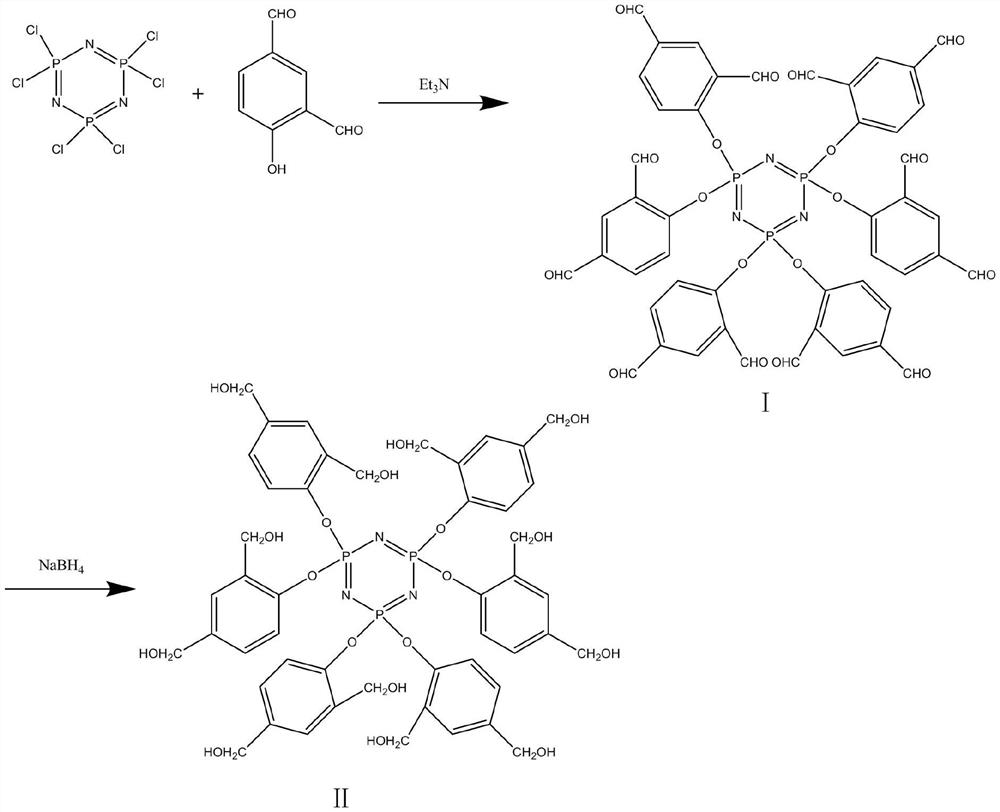

Bisphenol A cyanate ester resin prepolymer and preparation method thereof

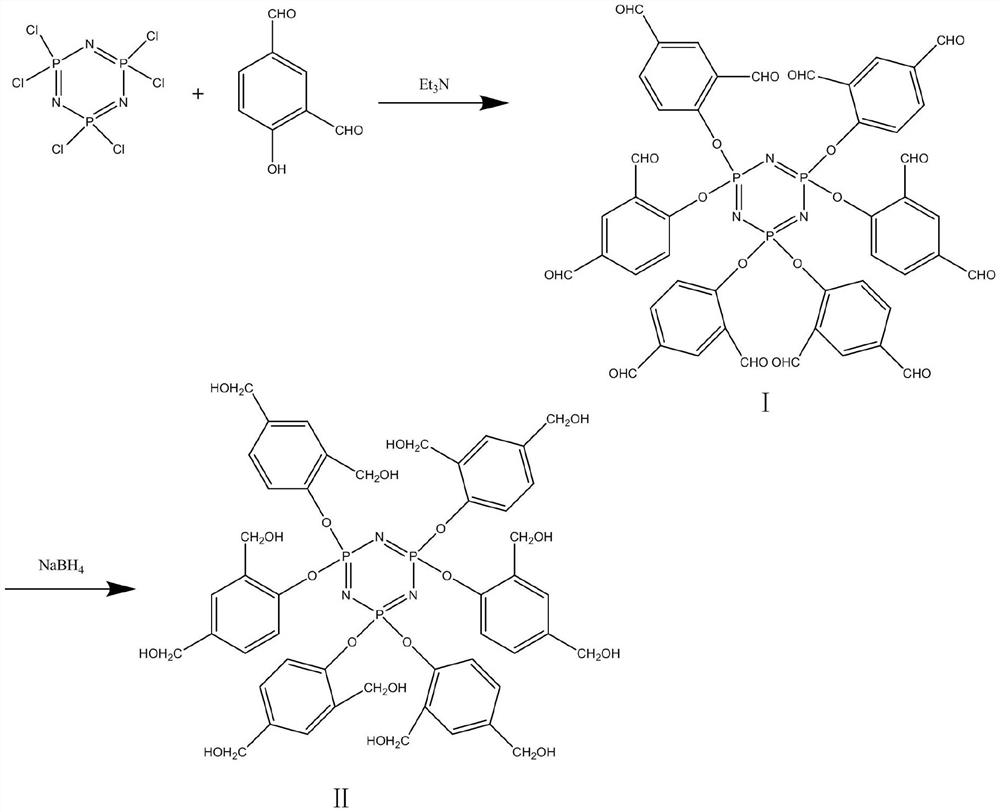

ActiveCN111848952AImprove polymerization curing efficiencyImprove toughnessGroup 5/15 element organic compoundsPolymer sciencePtru catalyst

The invention discloses a bisphenol A cyanate ester resin prepolymer and a preparation method thereof. The preparation method comprises the following steps of: heating and melting a bisphenol A type cyanate ester monomer, adding a prepared polymerization compatible catalyst and a composite moisture absorbent, carrying out a heat preservation reaction, terminating the reaction by monitoring a refraction coefficient, cooling, adding butanone, and cooling to obtain the bisphenol A type cyanate ester resin prepolymer. Compared with the traditional bisphenol A type cyanate ester resin prepolymer, the prepolymer has the advantages that the cyclic structure of cyclotriphosphazene has good compatibility with a bisphenol A type cyanate ester monomer and can participate in the polymerization reaction of the bisphenol A type cyanate ester monomer, the curing reaction rate is greatly increased, rigid units of a phosphazene ring and a benzene ring greatly improve the toughness of the prepolymer anddo not influence the tensile strength and the thermal performance, the cyclotriphosphazene core can exert a phosphorus-nitrogen synergistic flame-retardant effect, and the polymerization compatible catalyst improves the polymerization curing efficiency of the bisphenol A type cyanate ester monomer, and improves the toughness, heat resistance and flame retardancy of the bisphenol A type cyanate ester resin prepolymer.

Owner:YANGZHOU TECHIA MATERIAL CO LTD

Silicon rubber composite cable material and preparation method thereof

InactiveCN108659538AImprove heat resistanceImprove aging resistancePlastic/resin/waxes insulatorsCarbon fibersCarbon nanotube

The invention discloses a silicon rubber composite cable material and a preparation method thereof. The cable material comprises silicon rubber, ethylene propylene rubber, butadiene rubber, polyarylacetylene resin, stearic acid, zinc oxide, sulfur, 2, 4-dichlorobenzoyl peroxide, coupling agents, graphite, accelerants, anti-aging agents, modified fire retardants, 1, 4-cyclohexanedimethanol diglycidyl ether, carbon fibers, white mica and melamine polyphosphate. The modified fire retardants are prepared according to the process including the steps: gelatinizing starch; adding the starch into water; adding nano-sized magnesium oxide, zirconium oxide, iron oxide and carbon nano-tubes; performing ultrasonic treatment, drying, carbonization, crushing and sieving. The preparation method of the silicon rubber composite cable material is simple in process, and the prepared silicon rubber composite cable material is good in heat resistance and aging resistance and excellent in fire resistance.

Owner:李侠

Heat-resistant flame-retardant epoxy resin latent curing agent

The invention discloses a heat-resistant flame-retardant epoxy resin latent curing agent and a preparation method thereof, and belongs to the technical field of organic synthesis. According to the preparation method, a reaction of cyanuric chloride and a primary amino-containing imidazole compound is carried out at a molar ratio of 1:1 at 0-10 DEG C in a suitable solvent, then a melamine intermediate containing an imidazole group is produced by pressurized ammonolysis at 100 DEG C, finally a complex is produced by reacting with cyanuric acid according to a molar ratio of 1:1 in a hot water, and the latent curing agent is obtained by filtering, drying and crushing. The compounded substance of the latent curing agent prepared by the method and epoxy resin can be stored for a long period of time and can be cured at a medium temperature, and the cured product has high heat resistance and excellent flame retardancy.

Owner:广东固研电子材料有限公司

Preparation method of high-strength stamping-resistant and fireproof building material

The invention relates to a preparation method of a high-strength stamping-resistant and fireproof building material, and belongs to the technical field of building materials. The preparation method comprises the following steps: firstly pulverizing and mixing straws and log wood blocks, feeding the mixture and water into a reaction kettle, dropwise adding citric acid to obtain an acidic solution,then adding ferric chloride, stirring at a high temperature, then performing high temperature and high pressure reaction to obtain heat treatment reaction liquid, dropwise adding an alkali solution into the heat treatment reaction solution, then adding silicon dioxide for reaction to obtain reaction slurry, adding copper powder into the reaction slurry, shaking for a reaction, then adding sulfuricacid and stirring after the reaction, filtering the mixture to obtain a self-made fiber product, and finally, mixing the self-made fiber product with clay, perlite and other raw materials, then mixing the mixture with resin, feeding into an extruder for extrusion, and performing hot pressing and discharging to obtain the high-strength stamping-resistant and fireproof building material. The fiberis modified, so that the high-temperature-resistance, the flame retardant property and the mechanical strength of the fiber are improved, and the mechanical properties and the flame retardant strengthof the building material are enhanced; the preparation method has a good application prospect.

Owner:宁波柏尔环保科技有限公司

High-strength, waterproof and wear-resistant cable sheath material and preparation method thereof

The invention relates to the field of wires and cables, in particular to a high-strength, waterproof and wear-resistant cable sheath material and a preparation method thereof. The high-strength, waterproof and wear-resistant cable sheath material is prepared from, by weight, 70-100 parts of nitrile silicone rubber, 45-60 parts of styrene-butadiene rubber, 17-30 parts of chlorosulfonated polyethylene, 10-13 parts of butyl epoxy stearate, 10-18 parts of modified muscovite powder, 4-12 parts of zinc stannate, 5-7 parts of expanded perlite, 7-11 parts of vinyltriethoxysilane, 6-15 parts of aluminum hydroxide, 5-8 parts of semi-reinforced carbon black, 5-11 parts of nano-silica, 10-16 parts of filler reinforcer and 6-15 parts of protective agent. The cable sheath material is good in strength, toughness, heat resistance, waterproof property, corrosion resistance and flame retardance, excellent in comprehensive performance, and suitable for many fields.

Owner:ANHUI WANGDA COPPER DEV

Flame-retardant cable sheath and preparation method thereof

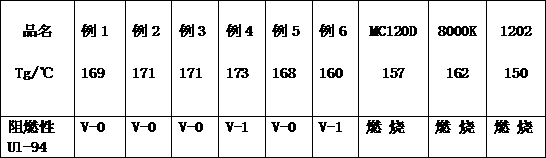

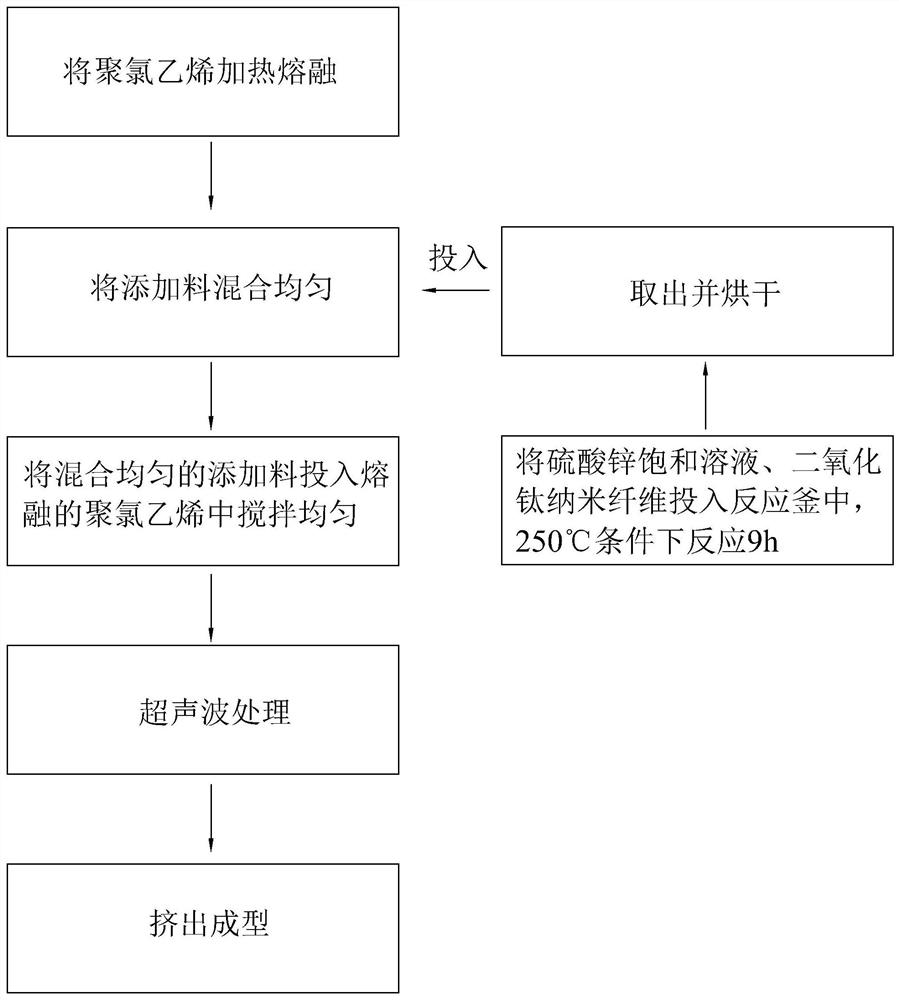

InactiveCN111690215AImprove flame retardant performanceEnhanced interactionPlastic/resin/waxes insulatorsCarbon layerPolyvinyl chloride

The invention relates to the field of wires and cables, and particularly discloses a flame-retardant cable sheath and a preparation method thereof. The sheath is prepared from, by weight, 90-100 partsof polyvinyl chloride; 4 to 7 parts of titanium dioxide nanometer fiber; 1-2 parts of antimony trioxide; and 4-6 parts of trichloroethyl phosphate. Polyvinyl chloride (PVC) has good flame retardant property, and SbCl3 generated by Cl and Sb in PVC combustion can play a role in capturing free radicals and isolating air, therefore, the antimony trioxide added into the polyvinyl chloride can generate a better flame-retardant effect on polyvinyl chloride. The titanium dioxide nanofibers provide a skeleton supporting effect for the charring process of the system in the thermal degradation processof the polymer; amorphous carbon particles are attached to a network framework to generate a continuous compact barrier carbon layer with few holes, the barrier effect of the expansion carbon layer ona polymer, a heat source and oxygen is enhanced, the further combustion process of the polymer is delayed, and the limit oxygen index of the system is increased.

Owner:温州网牌电线电缆有限公司

Waterproof flame-retardant acoustic panel and production process thereof

InactiveCN107311598AThe production process is simple and easy to controlImprove sound absorptionFiberPolyester

The invention discloses a waterproof flame-retardant acoustic panel and a production process thereof. The waterproof flame-retardant acoustic panel comprises the following raw materials in parts by weight: 40-60 parts of gypsum powder, 15-35 parts of bamboo carbon fibers, 10-20 parts of polyester fibers, 8-15 parts of glass fibers, 6-10 parts of attapulgite, 5-15 parts of blast furnace slag, 3-8 parts of calcium hydroxide, 1-5 parts of magnesium oxide, 0.5-3 parts of an inorganic adhesive, 1-3 parts of a water repellent and 0.5-1.5 parts of a flame retardant. The production process of the waterproof flame-retardant acoustic panel comprises the four steps of purification of attapulgite, preparation of a matrix material, preparation of a molding blank and natural curing. The waterproof flame-retardant acoustic panel is safe and environment-friendly in component, good in waterproof and flame-retardant effect, and resistant to sound and heat, and maintains the strength and the hardness of a gypsum board.

Owner:合肥慧林建材有限公司

Environmental-protection heatproof flame-retardation silicone rubber and preparation method thereof

The invention discloses an environmental-protection heatproof flame-retardation silicone rubber. The heatproof flame-retardation silicone rubber comprises the following components: methyl vinyl silicone rubber, carbon black, carboxyethyl phenyl hypophosphorous acid metal salt, melamine cyanurate, zinc borate, a silane coupling agent, zinc stearate, a plasticizer, sulfur powder, a promoter, and anantioxidant. The invention also provides a preparation method of the environmental-protection heatproof flame-retardation silicone rubber. The method comprises the following steps: adding methyl vinylsilicone rubber, carbon black, carboxyethyl phenyl hypophosphorous acid metal salt, melamine cyanurate, zinc borate, the silane coupling agent, the plasticizer, and the antioxidant in a mixing machine and uniformly mixing the raw materials, adding zinc stearate, sulphur and the promoter and uniformly mixing the materials to prepare a mother material, and adding the mother material in a vulcanizerfor sulfuration to prepare the environmental-protection heatproof flame-retardation silicone rubber. The silicon material of the heatproof flame-retardation silicone rubber has the advantages of highoxygen index, no halogen, safety, environmental protection, and wide application prospect.

Owner:天长市荣盛有机硅科技有限公司

Heat-resistant and flame-retardant bridge frame and preparation method thereof

InactiveCN109679294AImprove heat resistance and flame retardancyExcellent flame retardancyPlasticizerFire retardant

The invention provides a heat-resistant and flame-retardant bridge frame and a preparation method thereof, and relates to the technical field of bridge frame processing. The heat-resistant and flame-retardant bridge frame is made of the following raw materials in parts by weight: 80-100 parts of bisphenol-A epoxy resin, 6-10 parts of unsaturated polyester, 3-4 parts of alumina ceramics, 1-3 partsof azobenzene, 2-4 parts of polypropylene glycol, 2-6 parts of polyvinyl formal, 2-4 parts of phosphonitrilic chloride trimer, 1-3 parts of nano-silica, 0.8-1.6 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 2-4 parts of a plasticizer, 1-3 parts of a flame retardant and 0.2-0.4 part of a defoamer. According to the invention, the defects of the prior art are overcome, the flame retardant performance of the traditional glass steel bridge frame is improved, and by adopting the preparation method of one-time molding after the raw materials are mixed, the production efficiency of a product is effectively improved, the production cost is reduced, and the heat-resistant and flame-retardant bridge frame is suitable for popularization and production.

Owner:安徽祥君电气有限公司

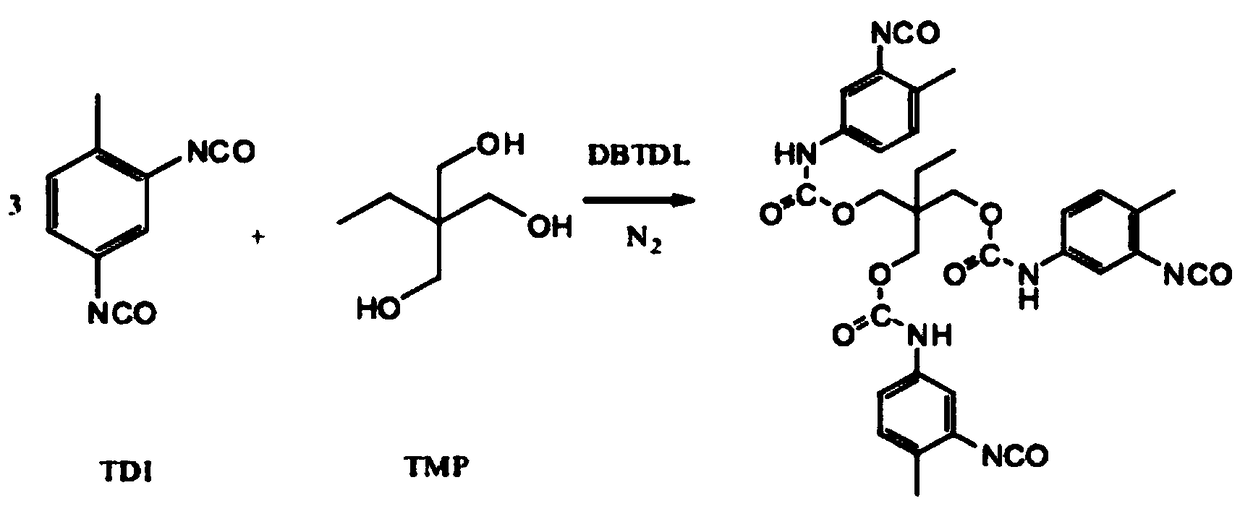

A kind of environmental protection type nitrocellulose leather brightener and preparation method thereof

The invention relates to the field of leather care, in particular to an environment-friendly nitrocotton leather brightener and a preparation method thereof. The environment-friendly nitrocotton leather brightener of the present invention comprises the following components in parts by weight: 10 to 30 parts of nitrocellulose , 5-20 parts of alkyd resin, 2-20 parts of melamine formaldehyde resin, 35-65 parts of organic solvent, 6-12 parts of plasticizer, 5-30 parts of auxiliary agent, 1-10 parts of castor oil. The nitrocotton leather brightener of the invention is energy-saving, environment-friendly, low in price, good in heat resistance, good in use effect and beneficial to prolonging the service life of leather.

Owner:DONGGUAN UNIV OF TECH

A heat-resistant and flame-retardant latent curing agent for epoxy resin

ActiveCN110016123BImprove heat resistance and flame retardancyHeat resistantPolymer scienceOrganic synthesis

The invention discloses a latent curing agent for heat-resistant and flame-retardant epoxy resin and a preparation method thereof, belonging to the technical field of organic synthesis; the latent curing agent of the invention is composed of cyanuric chloride and imidazole compounds containing primary amino groups React with a 1:1 mole ratio at 0-10°C in a suitable solvent, then pressurize ammonia at 100°C to generate a melamine intermediate containing an imidazole group, and finally mix with cyanuric acid at a ratio of 1:1 mole Than generate complexes in hot water, filtered, dried, and crushed. The latent curing agent prepared by the method of the invention and the epoxy resin compound can be stored for a long time and can be cured at medium temperature, and the cured product has high heat resistance and excellent flame retardancy.

Owner:广东固研电子材料有限公司

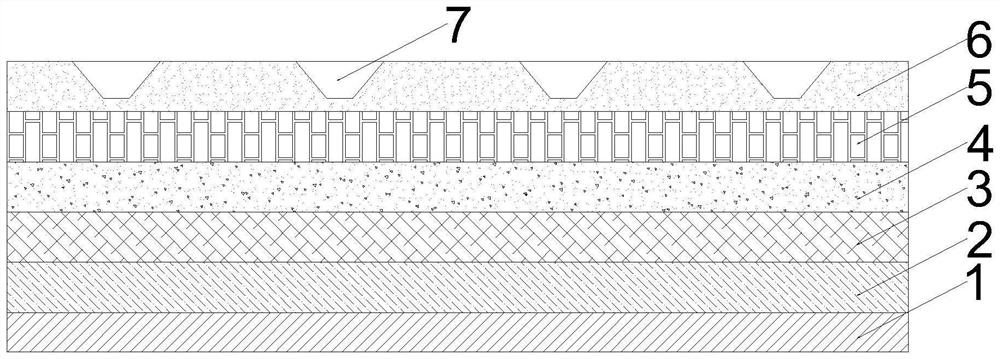

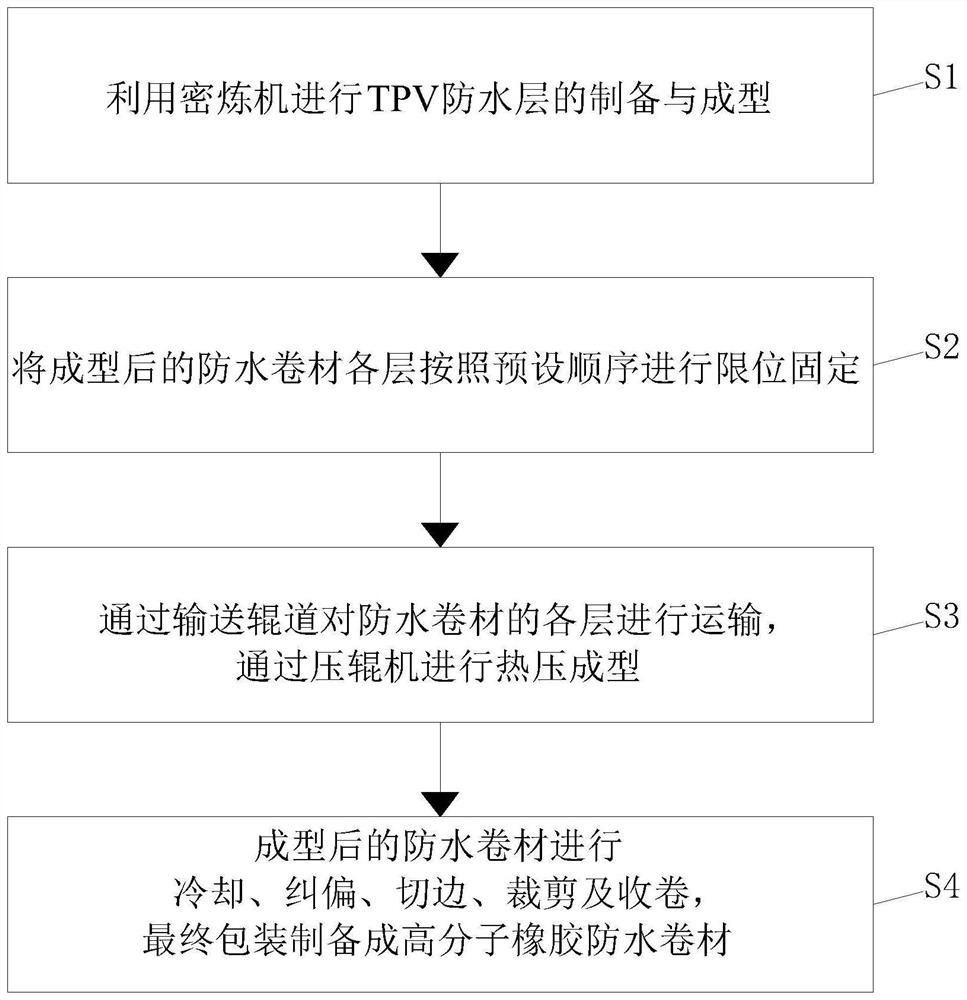

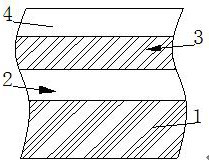

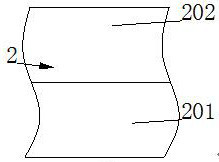

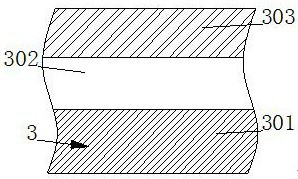

Polymer rubber waterproof coiled material based on TPV (thermoplastic vulcanizate) main material and preparation method of polymer rubber waterproof coiled material

PendingCN114806442AIncrease elasticityGood dimensional stabilityRoof covering using flexible materialsFilm/foil adhesivesElastomerThermoplastic

The invention discloses a polymer rubber waterproof roll based on a TPV main material and a preparation method. The polymer rubber waterproof roll comprises a self-adhesion base layer, a heat preservation and insulation layer, a sound insulation layer, a fiber core wire layer, a TPV waterproof layer and an isolation protection layer which are sequentially connected from bottom to top. A plurality of anti-wrinkling holes which are arranged at equal intervals and distributed in a rectangular mode are formed in the top of the isolation protection layer, and the fiber core wire layer is of a grid woven structure. The modified TPV elastomer is used as a core material, so that the modified TPV elastomer has good rebound resilience, dimensional stability, high impact resistance and high mechanical strength; meanwhile, complex and tedious vulcanization procedures are not needed, processing can be directly carried out like common thermoplastic plastics, the technological procedures are simplified, and the forming period is shortened; and in the aspect of sustainable utilization, processing residual materials or waste materials can be recycled for reprocessing treatment, so that the material has a good regeneration recycling characteristic, and has positive significance on environmental protection while the cost is reduced.

Owner:上海豫宏(金湖)防水科技有限公司

A high-strength wear-resistant and tear-resistant rubber material

Owner:宁国日格美橡塑股份有限公司

Preparation process of light composite structure toughened glass

InactiveCN111844960AImprove toughnessAvoid damageSynthetic resin layered productsLaminationToughened glassToughness

The invention belongs to the technical field of tempered glass preparation, and particularly relates to a preparation process of light composite structure tempered glass. The tempered glass comprisesa tempered glass main body, a tough layer is fixedly adhered to the surface of the tempered glass main body, and an anti-corrosion layer is fixedly adhered to the surface of the tough layer. Accordingto the invention, through the bonding of the tough layer, the toughness of the whole structure is effectively improved during use, and therefore, the damage to the structure due to overlarge stress is avoided; through the bonding of the anti-corrosion layer, the anti-corrosion capability of the whole structure is effectively improved, and the damage to the structure caused by external corrosion in long-time use is avoided; and quartz sand and a flame-retardant coordinating agent are used, so that the heat-resistant and flame-retardant capacity of the whole structure is effectively improved, and the situation that the structure spontaneously combusts and melts under the high-temperature condition and normal use is thus affected is avoided.

Owner:YANGZHOU HENGTAI GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com