A kind of environmental protection type nitrocellulose leather brightener and preparation method thereof

A technology of nitrocellulose and brightening agent, applied in chemical instruments and methods, polishing compositions and other directions, can solve the problems of poor stability of nitrocellulose emulsion, high flammability and explosiveness, and unsatisfactory rotation speed, and achieves improvement. Nursing effect, longevity improvement, emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

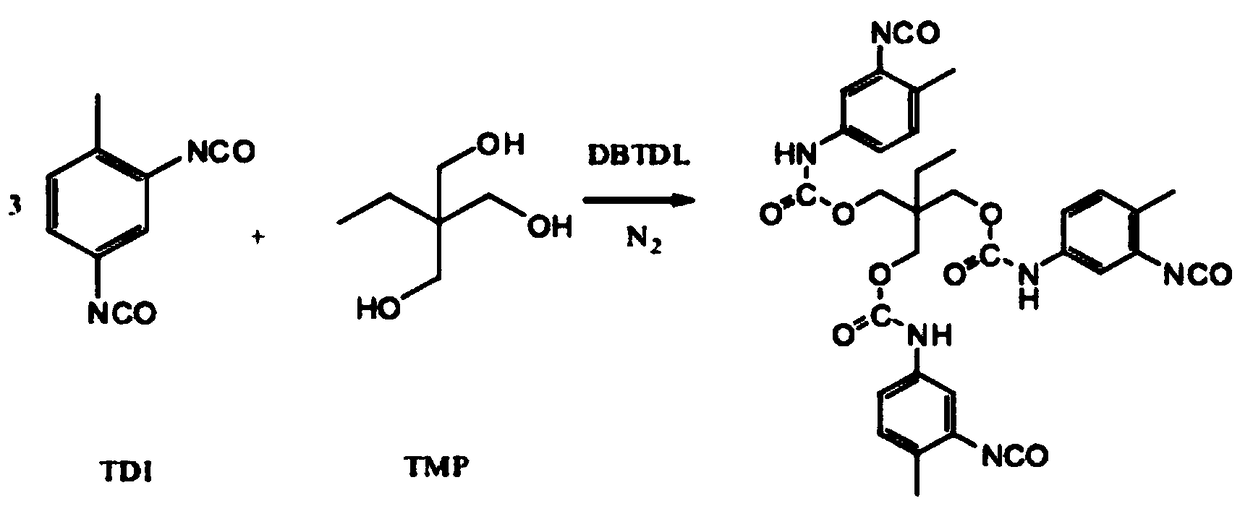

Method used

Image

Examples

Embodiment 1

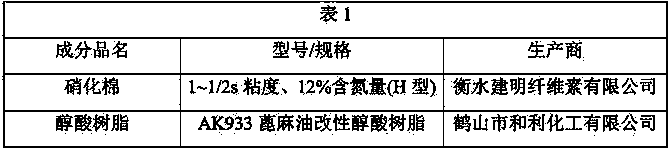

[0022] Environmentally friendly nitrocellulose leather brightener, comprising the following components in parts by weight, 15 parts of nitrocellulose, 9 parts of alkyd resin, 7 parts of melamine formaldehyde resin, 22 parts of cyclohexanone, 10 parts of butyl acetate, ethyl acetate 14 parts, ethanol 3 parts, dibutyl phthalate 8 parts, butanol 10 parts, castor oil 2 parts.

[0023] The preparation method of environment-friendly type nitrocellulose leather brightener comprises the following steps, a, oil phase preparation: drop into the organic solvent of formula quantity in dissolving kettle, the mixture of cyclohexanone, butyl acetate, ethyl acetate and ethanol, stir, Make the organic solvent mix evenly, then drop into the nitrocellulose of formula quantity under stirring condition, continue to stir, then drop into the melamine formaldehyde resin of formula quantity, then drop into the butylene phthalate that plays plasticizer effect of formula quantity, stir Evenly for subseq...

Embodiment 2

[0025] Environmentally friendly nitrocellulose leather brightener, comprising the following components in parts by weight, 15 parts of nitrocellulose, 9 parts of alkyd resin, 7 parts of melamine formaldehyde resin, 22 parts of cyclohexanone, 10 parts of butyl acetate, ethyl acetate 14 parts, ethanol 5 parts, dibutyl phthalate 8 parts, butanol 10 parts.

[0026] The preparation method of environment-friendly type nitrocellulose leather brightener comprises the following steps, a, oil phase preparation: drop into the organic solvent of formula quantity in dissolving kettle, the mixture of cyclohexanone, butyl acetate, ethyl acetate and ethanol, stir, Make the organic solvent mix evenly, then drop into the nitrocellulose of formula quantity under stirring condition, continue to stir, then drop into the melamine formaldehyde resin of formula quantity, then drop into the butylene phthalate that plays plasticizer effect of formula quantity, stir After uniformity, it is ready for use...

Embodiment 3

[0028] Environmentally friendly nitrocellulose leather brightener, comprising the following components in parts by weight, 15 parts of nitrocellulose, 17 parts of alkyd resin, 7 parts of melamine formaldehyde resin, 22 parts of cyclohexanone, 10 parts of butyl acetate, ethyl acetate 14 parts, ethanol 3 parts, butanol 10 parts, castor oil 2 parts.

[0029]The preparation method of environment-friendly type nitrocellulose leather brightener comprises the following steps, a, oil phase preparation: drop into the organic solvent of formula quantity in dissolving kettle, the mixture of cyclohexanone, butyl acetate, ethyl acetate and ethanol, stir, Mix the organic solvent evenly, then put in the formula amount of nitrocellulose under the condition of stirring, continue to stir, then put in the formula amount of melamine formaldehyde resin, stir well and set aside; b. Water phase preparation: take another reactor and add The butanol, castor oil and alkyd resin that play auxiliary agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com