Polymer rubber waterproof coiled material based on TPV (thermoplastic vulcanizate) main material and preparation method of polymer rubber waterproof coiled material

A waterproof membrane and polymer technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of service life and waterproof effect, waterproof membrane heat resistance, poor flame retardancy, etc., to achieve Efficient anti-oxidation and anti-aging ability, improved anti-static ability, improved heat resistance and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

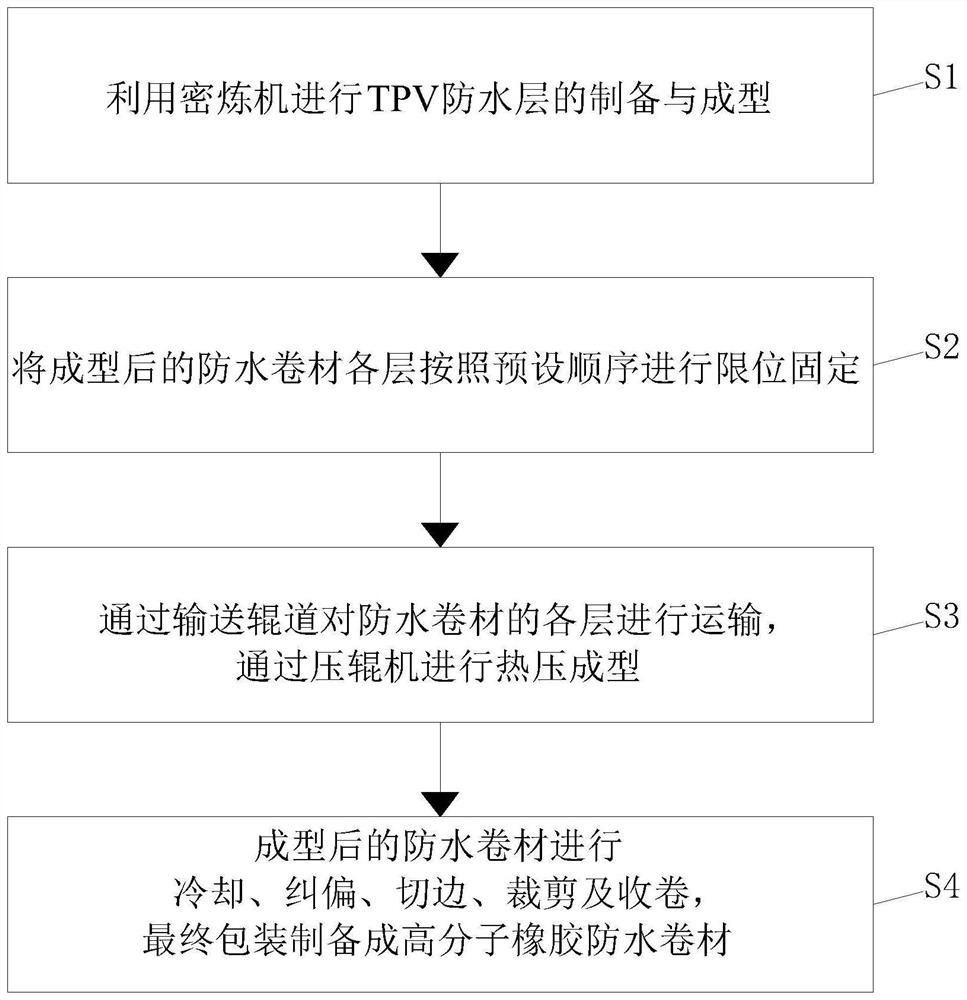

[0087] According to another embodiment of the present invention, as figure 2 As shown, a preparation method of a polymer rubber waterproofing membrane based on a TPV main material is also provided, and the preparation method comprises the following steps:

[0088] S1, use an internal mixer to prepare and shape the TPV waterproof layer 4;

[0089] Wherein, step S1 includes:

[0090] S11, preparing modified TPV elastomer;

[0091] At present, two methods are often used for the preparation of modified TPV elastomers, namely one-step method and two-step method.

[0092] The equipment usually used in the one-step method is a twin-screw extruder, which completes the dynamic vulcanization process inside the screw through the method of segmented feeding. Because the twin-screw extruder can provide a strong shear force, the blend can be well mixed, and at the same time, the residence time can be precisely set between each stage. On the basis of ensuring continuous production, the ...

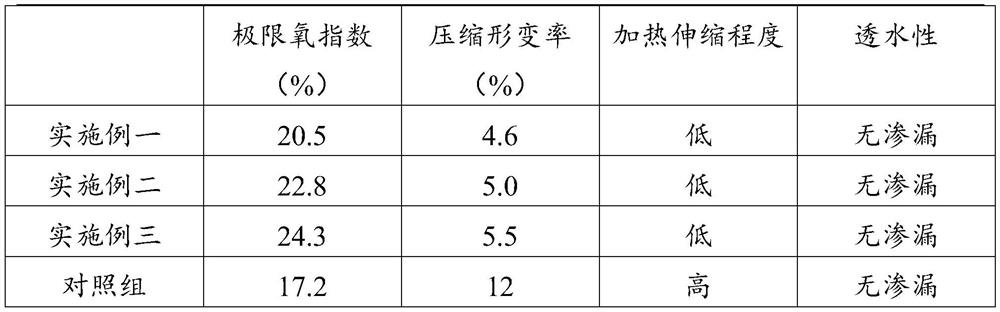

Embodiment 1

[0115] 90 parts of modified TPV elastomer; 20 parts of ABS plastic; 2 parts of carbon nanotube masterbatch; 2 parts of dopamine modified sodium-based montmorillonite; 2 parts of antioxidant; 3 parts of plasticizer; 2 parts of dispersant; anti-aging 1 part of the agent; 1 part of the preservative.

[0116] The TPV waterproof layer 4 is prepared according to the above composition ratio, and a complete polymer waterproof membrane is prepared through the thermoplastic processing process of the waterproof membrane, and the finished product is laid in the experimental control area.

Embodiment 2

[0118] 105 parts of modified TPV elastomer; 30 parts of ABS plastic; 3 parts of carbon nanotube masterbatch; 5 parts of dopamine modified sodium-based montmorillonite; 5 parts of antioxidant; 4 parts of plasticizer; 3 parts of dispersant; anti-aging 3 parts of the agent; 2 parts of the preservative.

[0119] The TPV waterproof layer 4 is prepared according to the above composition ratio, and a complete polymer waterproof membrane is prepared through the thermoplastic processing process of the waterproof membrane, and the finished product is laid in the experimental control area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com