Preparation method of high-strength stamping-resistant and fireproof building material

A fire-proof building, stamping-resistant technology, applied in the field of building materials, can solve the problems of insufficient compressive strength, poor fire resistance, decreased durability, etc., to enhance mechanical properties, improve mechanical properties and compressive strength, and enhance bonding. The effect of firm strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

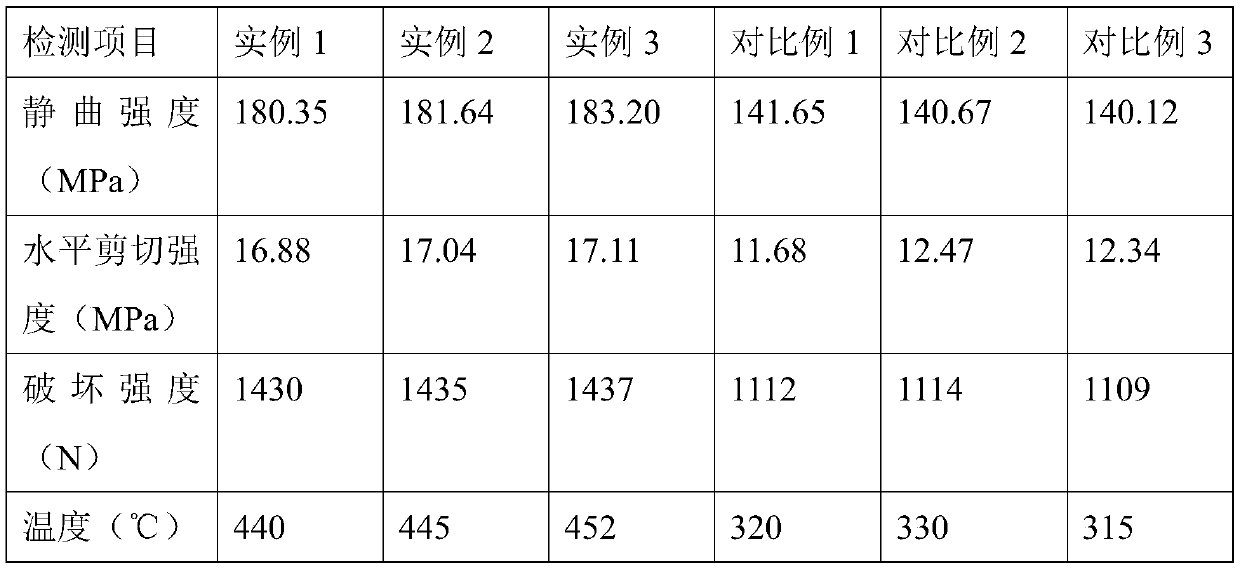

Examples

Embodiment 1

[0032] The log block is preferably: eucalyptus

[0033] Preparation of heat treatment reaction solution:

[0034] Put rice straw and logs into a pulverizer at a mass ratio of 1:5 to pulverize to obtain a mixture, put the mixture and distilled water at a mass ratio of 1:10 and mix them evenly in a reaction kettle to obtain a mixed slurry, which is poured into the reaction kettle Add dropwise citric acid solution with a mass fraction of 10% of the mixed slurry mass and 15%, and continue stirring with a stirring device at a speed of 500r / min for 30min to obtain an acidic solution;

[0035] Add ferric chloride powder with an acidic solution mass of 3% to the above reaction kettle, raise the temperature in the reaction kettle to 80°C, stir with a stirrer at a speed of 500r / min for 30min under constant temperature conditions to prepare a mixed reaction solution, and seal the reaction Reactor, fill the reactor with nitrogen to increase the pressure in the reactor to 1.3MPa, raise th...

Embodiment 2

[0043] The log block is preferably: pine

[0044] Preparation of heat treatment reaction solution:

[0045] Put rice straw and logs into a pulverizer at a mass ratio of 1:5 to pulverize to obtain a mixture, put the mixture and distilled water at a mass ratio of 1:10 and mix them evenly in a reaction kettle to obtain a mixed slurry, which is poured into the reaction kettle Add dropwise a citric acid solution with a mass fraction of 13% of the mixed slurry mass and a mass fraction of 18%, and continue stirring with a stirring device at a speed of 550r / min for 35min to obtain an acidic solution;

[0046] Add ferric chloride powder with an acidic solution mass of 4% to the above reaction kettle, raise the temperature in the reaction kettle to 90°C, stir with a stirrer at a speed of 550r / min for 35min under constant temperature conditions to prepare a mixed reaction solution, and seal the reaction Reactor, fill the reactor with nitrogen to increase the pressure in the reactor to 1...

Embodiment 3

[0054] The log block is preferably: Poplar

[0055] Preparation of heat treatment reaction solution:

[0056] Put rice straw and logs into a pulverizer at a mass ratio of 1:5 to pulverize to obtain a mixture, put the mixture and distilled water at a mass ratio of 1:10 and mix them evenly in a reaction kettle to obtain a mixed slurry, which is poured into the reaction kettle Add 10-15% of the mass of the mixed slurry dropwise with a citric acid solution with a mass fraction of 20%, and continue stirring with a stirring device at a speed of 600r / min for 40min to obtain an acidic solution;

[0057] Add ferric chloride powder with an acidic solution mass of 5% to the above reaction kettle, raise the temperature in the reaction kettle to 100°C, stir with a stirrer at a speed of 600r / min for 40min under constant temperature conditions to prepare a mixed reaction solution, and seal the reaction Reactor, fill the reactor with nitrogen to increase the pressure in the reactor to 1.5MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com