Production process for manufacturing flame-retardant canvas bag from waste textiles

A technology of waste textiles and production technology, which is applied in the direction of textiles, papermaking, textiles, flame-retardant fibers, etc. It can solve the problems of lack of moisture absorption and breathability, strength, heat resistance, and flame-retardant properties of canvas bags, and achieve improved cleanliness and improved Moisture absorption and air permeability, promote the effect of continuous cutting and crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

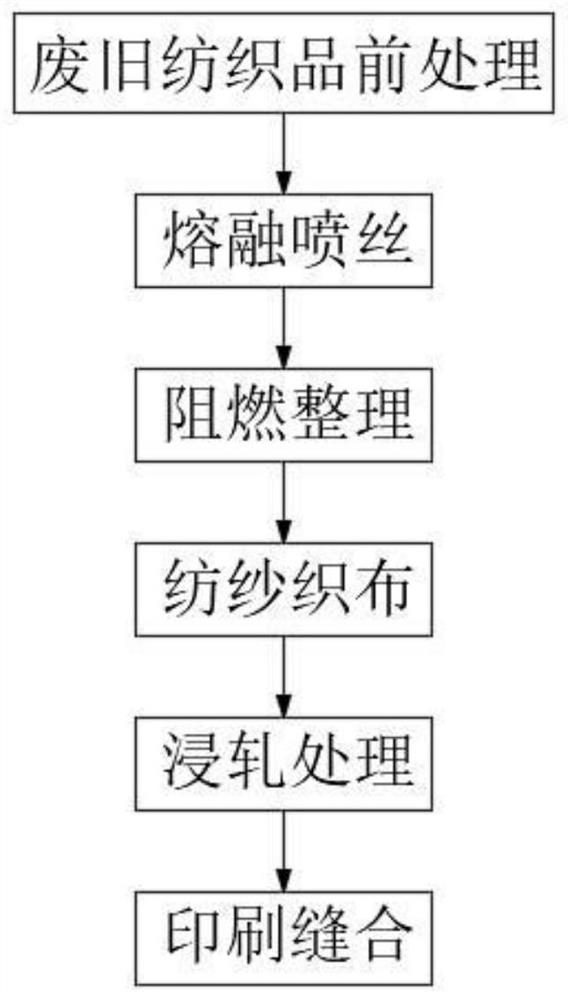

[0038] Such as figure 1 As shown, this embodiment provides a production process for using waste textiles to manufacture flame-retardant canvas bags, including the following steps:

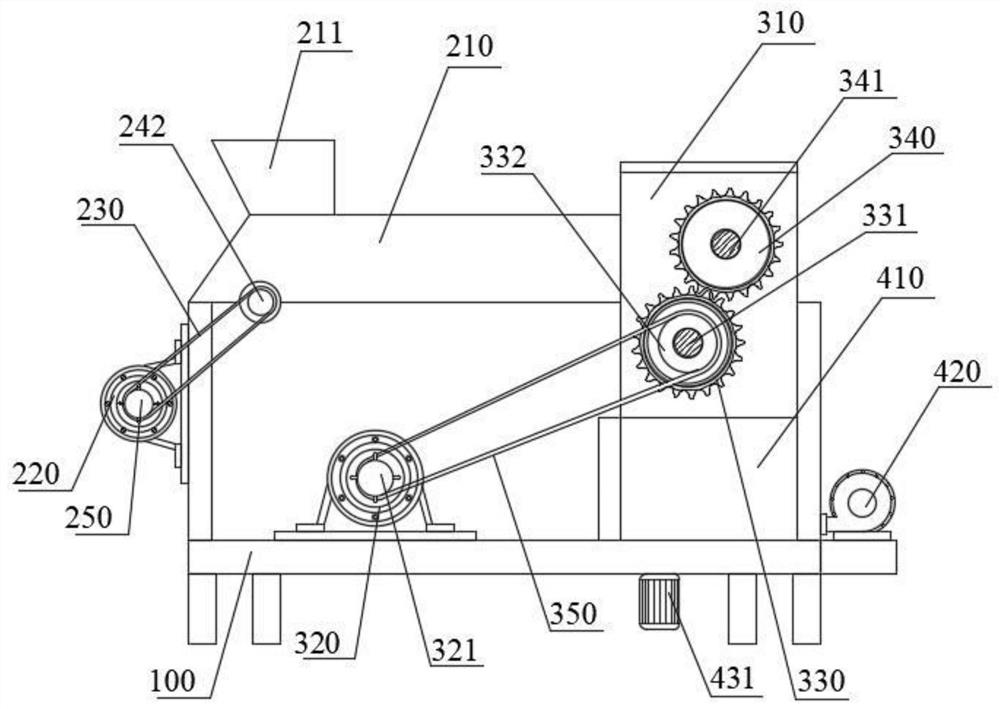

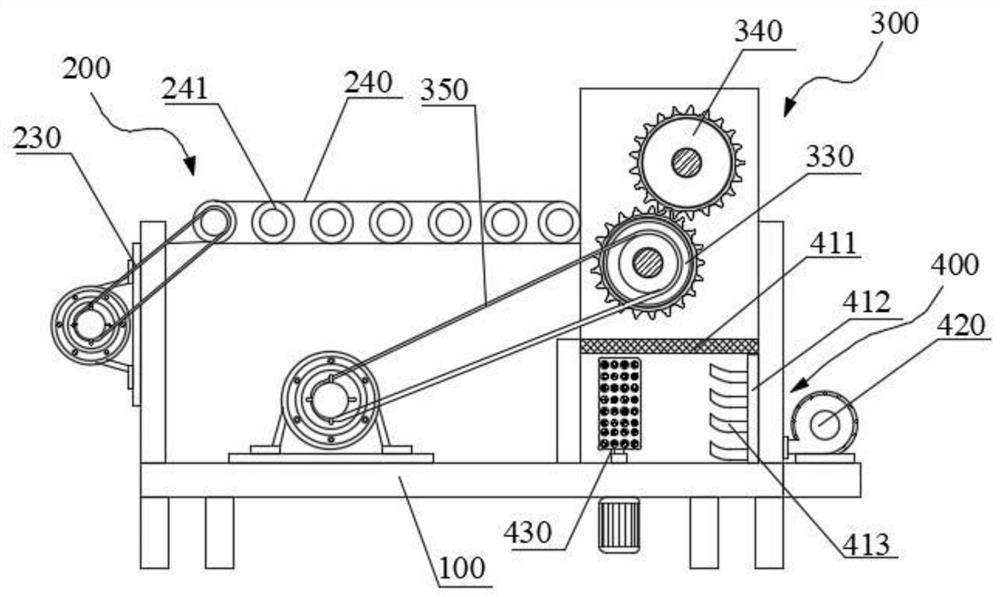

[0039] Pre-treatment of waste textiles: After cleaning and drying the collected waste textiles, the continuous cutting, crushing and magnetic separation processes are carried out through the integrated equipment of cutting, crushing and magnetic separation to obtain short filaments of textile fibers; The silk is impregnated with cleaning liquid, filtered, and dried to obtain separated fiber short filaments; wherein, the cleaning liquid is prepared by mixing the following raw materials in parts by weight: 8-15 parts of hydroxyethyl cellulose, 5-10 parts of fatty alcohol polyoxyethylene ether , 3-8 parts of sodium bicarbonate, 2-6 parts of lauric acid diethanolamide, 8-15 parts of citric acid, and 25-40 parts of ethanol; the waste textiles are selected from the waste textiles of polyester fiber fabri...

Embodiment 2

[0047] The difference between this example and Example 1 is that the cleaning solution is prepared by mixing the following raw materials in parts by weight: 14 parts of hydroxyethyl cellulose, 9 parts of fatty alcohol polyoxyethylene ether, 6 parts of sodium bicarbonate, dilauric acid 5 parts of ethanolamide, 12 parts of citric acid, 35 parts of ethanol.

[0048] The flame retardant is prepared from the following raw materials in parts by weight: 5 parts of melamine cyanurate, 3 parts of antimony trioxide, 11 parts of fatty alcohol polyoxyethylene ether, 4 parts of pentaerythritol, and 22 parts of ethanol.

[0049] The impregnation solution is prepared from the following raw materials in parts by weight: 9 parts of fatty alcohol polyoxyethylene ether, 5 parts of epoxy resin, 3 parts of melamine cyanurate, and 252 parts of soft water.

Embodiment 3

[0051] The difference between this example and Example 1 is that the cleaning solution is prepared by mixing the following raw materials in parts by weight: 13 parts of hydroxyethyl cellulose, 8 parts of fatty alcohol polyoxyethylene ether, 6 parts of sodium bicarbonate, dilauric acid 5 parts of ethanolamide, 13 parts of citric acid, 35 parts of ethanol.

[0052] The flame retardant is prepared from the following raw materials in parts by weight: 5 parts of melamine cyanurate, 2 parts of antimony trioxide, 10 parts of fatty alcohol polyoxyethylene ether, 4 parts of pentaerythritol, and 18 parts of ethanol.

[0053] The dipping solution is prepared from the following raw materials in parts by weight: 8 parts of fatty alcohol polyoxyethylene ether, 4 parts of epoxy resin, 2 parts of melamine cyanurate, and 250 parts of soft water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com