Flame-retardant cable sheath and preparation method thereof

A technology for flame-retardant cables and sheaths, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as limited flame-retardant effects, achieve enhanced interaction force, improve heat-resistant flame-retardant performance, and connect tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A flame-retardant cable sheath, the raw material components are shown in Table 1 in parts by weight.

[0051] Wherein, zinc sulfate is loaded on the titanium dioxide nanofiber, and the loading method comprises the following steps:

[0052] S1, put the saturated solution of zinc sulfate and titanium dioxide nanofibers into the reaction kettle, and react at 250°C for 9 hours;

[0053] S2, take out and dry.

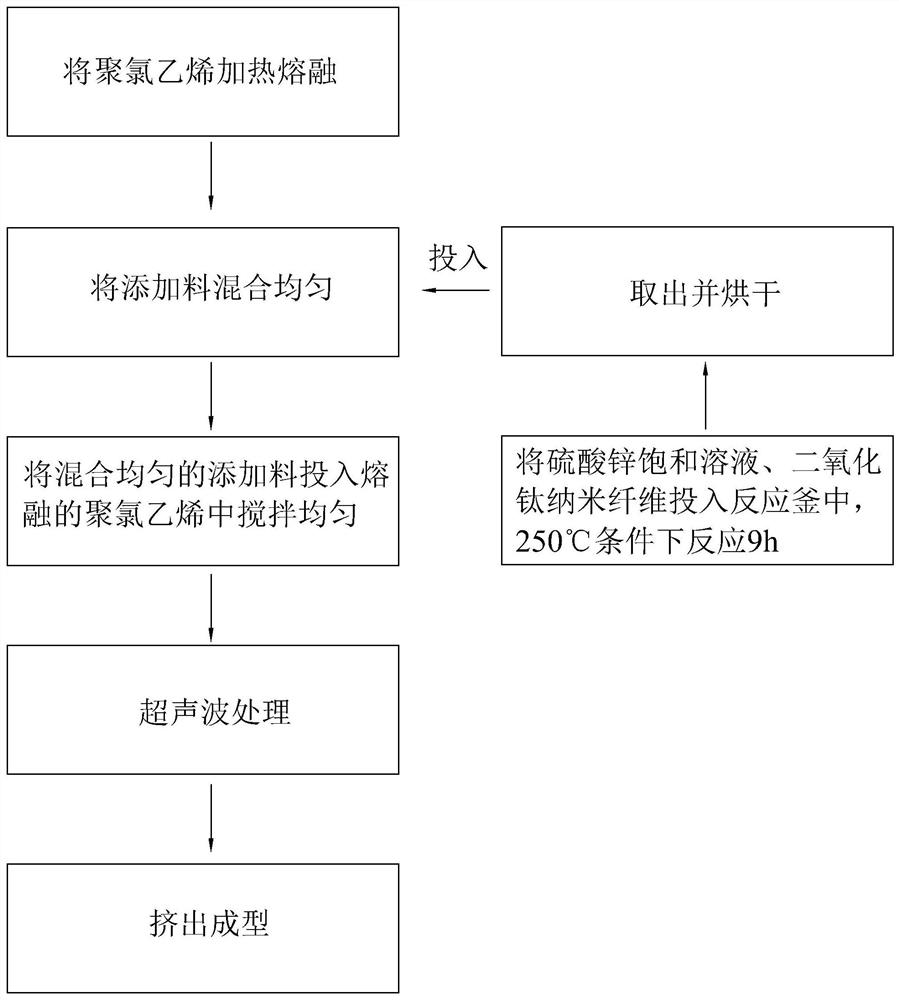

[0054] Such as figure 1 Shown, the preparation method of flame retardant cable sheath comprises the following steps:

[0055] S1, loading zinc sulfate on titanium dioxide nanofibers for subsequent use;

[0056] S2, heating and melting polyvinyl chloride;

[0057] S3, uniformly mixing titanium dioxide nanofibers loaded with zinc sulfate, antimony trioxide, trichloroethyl phosphate, zinc borate, aluminum hypophosphite, ammonium polyphosphate, and pentaerythritol;

[0058] S4, putting the uniformly mixed additive into the molten polyvinyl chloride and stirring evenl...

Embodiment 2

[0062] A flame-retardant cable sheath, the raw material components are shown in Table 1 in parts by weight.

[0063] The preparation method of flame retardant cable sheath comprises the following steps:

[0064] S1, heating and melting polyvinyl chloride;

[0065] S2, uniformly mixing titanium dioxide nanofibers, antimony trioxide, trichloroethyl phosphate, zinc borate, aluminum hypophosphite, ammonium polyphosphate, and pentaerythritol;

[0066] S3, putting the uniformly mixed additive into the molten polyvinyl chloride and stirring evenly;

[0067] S4, ultrasonic treatment for 1 hour, extrusion molding.

Embodiment 3

[0069] A flame-retardant cable sheath, the raw material components are shown in Table 1 in parts by weight.

[0070] Wherein, zinc sulfate is loaded on the titanium dioxide nanofiber, and the loading method comprises the following steps:

[0071] S1, put the saturated solution of zinc sulfate and titanium dioxide nanofibers into the reaction kettle, and react at 250°C for 9 hours;

[0072] S2, cooled to room temperature, washed 5 times with distilled water;

[0073] S3, take out and dry.

[0074] The preparation method of flame retardant cable sheath comprises the following steps:

[0075] S1, loading zinc sulfate on titanium dioxide nanofibers for subsequent use;

[0076] S2, heating and melting polyvinyl chloride;

[0077] S3, uniformly mixing titanium dioxide nanofibers loaded with zinc sulfate, antimony trioxide, trichloroethyl phosphate, zinc borate, aluminum hypophosphite, ammonium polyphosphate, and pentaerythritol;

[0078] S4, putting the uniformly mixed additive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com