Method for synthesizing heat resisting flame-retarded resin emulsion

A technology of flame retardant resin and synthesis method, which is applied in the field of synthesis of styrene resin emulsion, can solve the problems of unsatisfactory cost performance, increased process difficulty, serious PC resin degradation, etc., and achieves ideal yield and stability, Ease of reaction and wide range of composition adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

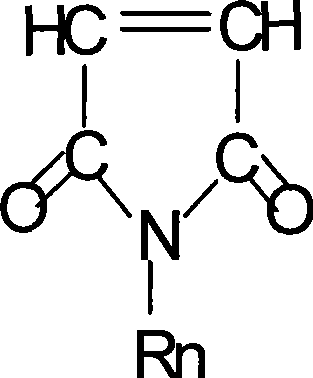

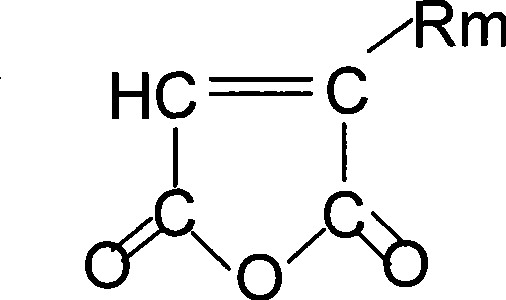

[0037] At 20°C, add 100 parts of desalted water and 2.7 parts of sodium lauryl sulfate into the emulsifier, turn on the stirring, control the rotation speed at about 60-100 rpm, and prepare emulsifier 2 emulsion (c). Mix 10 parts of N-phenylmaleimide, 20 parts of tribromophenyl maleic anhydride, 44.5 parts of styrene, 24.5 parts of acrylonitrile, 0.2 parts of azobisisobutyronitrile, and 0.2 parts of mercaptan, and start Stir to form a homogeneous monomer mixture solution (b). After mixing and dissolving 0.5 part of styrene, 0.5 part of acrylonitrile and 0.1 part of azobisisobutyronitrile, mix 1 part of sodium lauryl sulfate with 30 parts of water to make emulsifier 1 emulsion and mix it with the just dissolved benzene Mix the solution of ethylene, acrylonitrile and initiator into the reactor, stir until the system forms primary emulsion (a), raise the temperature to 75°C, and keep the temperature at a constant temperature for 10 minutes after the temperature of the water phase...

Embodiment 2

[0044] When the temperature is 20°C, add 100 parts of desalinated water, 2.0 parts of sodium lauryl sulfate, and 1.0 part of synthetic fatty acid potassium into the emulsifier, start stirring, and control the speed at about 60-100 rpm to configure emulsifier 2 emulsion (c) . 10 parts of N-phenylmaleimide, 30 parts of tribromophenyl maleic anhydride, 29.5 parts of α-methylstyrene, 29.5 parts of acrylonitrile, 0.2 parts of azobisisoheptanonitrile, 0.2 parts of t-dodecyl The carbon mercaptans are mixed and stirring is started to form a homogeneous monomer mixture solution (b). After mixing and dissolving 0.5 part of α-methylstyrene, 0.5 part of acrylonitrile and 0.1 part of azobisisobutyronitrile, mix 0.8 part of sodium lauryl sulfate, 0.4 part of synthetic fatty acid potassium and 30 parts of water to make an emulsifier 1 emulsion and mixed with the solution of just dissolved styrene, acrylonitrile and initiator, put into the reactor, stir until the system forms a primary emuls...

Embodiment 3

[0050] When the temperature is 20°C, add 100 parts of desalinated water, 2.0 parts of sodium lauryl sulfate, and 1.0 part of synthetic fatty acid potassium into the emulsifier, start stirring, and control the speed at about 60-100 rpm to configure emulsifier 2 emulsion (c) . 20 parts of N-phenylmaleimide, 15 parts of m-bromophenyl maleic anhydride, 34.0 parts of styrene, 29.5 parts of acrylonitrile, 0.25 parts of azobisisobutyronitrile, 0.19 parts of tertiary dodecyl mercaptan Mixing is performed and agitation is turned on to form a homogeneous monomer mixture solution (b). After mixing and dissolving 1.0 part of styrene, 0.5 part of acrylonitrile, 0.05 part of azobisisoheptanonitrile and 0.01 part of tert-dodecyl mercaptan, mix 1 part of sodium lauryl sulfate with 40 parts of water to make an emulsifier 1 emulsion and mixed with the solution of just dissolved styrene, acrylonitrile, initiator and regulator, put into the reactor, stir until the system forms primary emulsion (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com