Bisphenol A cyanate ester resin prepolymer and preparation method thereof

A type of cyanate ester and prepolymer technology, applied in the field of cyanate ester resin, can solve the problems of increasing the stability and storage time of the prepolymer, improve the polymerization curing efficiency, increase the toughness and heat resistance and flame retardant performance, The effect of increasing the curing reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A bisphenol A cyanate ester resin prepolymer of this embodiment is composed of bisphenol A cyanate ester monomers, polymerization compatible catalysts, and composite hygroscopic agents through heat preservation and stirring reaction. When the refractive index reaches 1.586, the temperature is lowered , Post-processing;

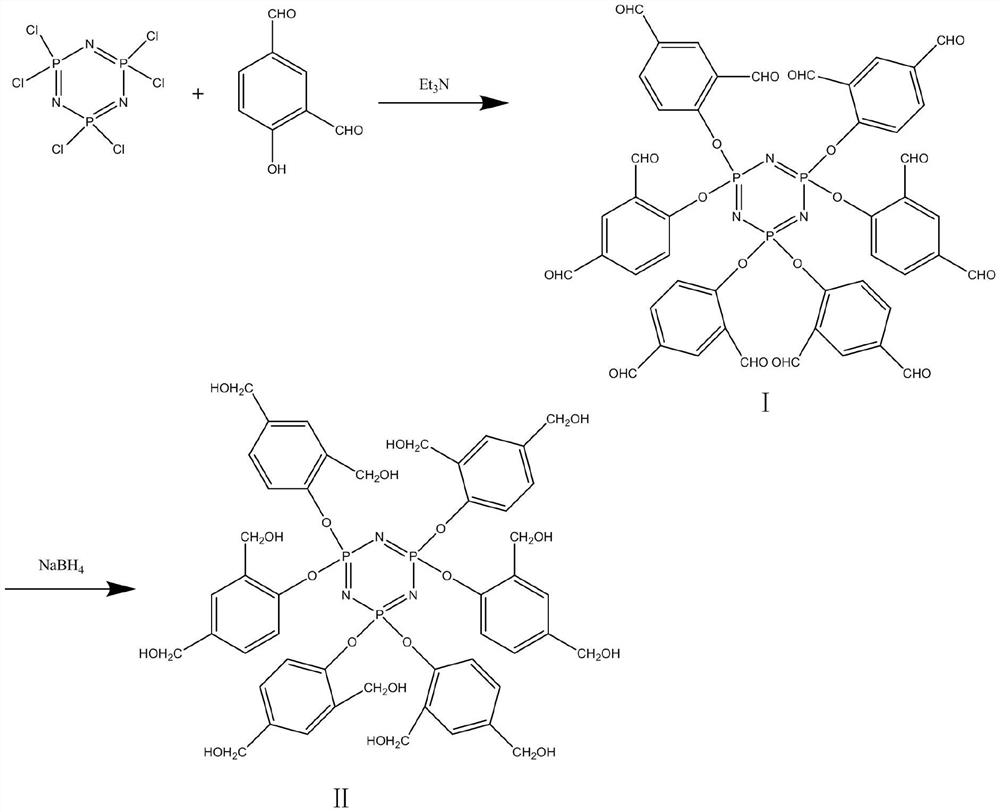

[0030] The synthesis reaction formula of the polymerization compatible catalyst is as follows:

[0031]

[0032] The composite moisture absorbent is obtained by polymerization reaction of diatomaceous earth, anhydrous magnesium sulfate and super absorbent acrylic resin under the action of a crosslinking agent and an initiator.

[0033] The preparation method of the polymerization compatible catalyst is as follows:

[0034] S1. Add 930g (6.2mol) of 4-hydroxy-1,3-phthalaldehyde, 16740g of solvent tetrahydrofuran, and then add 647.62g (6.4mol) of triethylamine to the reaction kettle, increase the temperature to 70°C, and stir at 460rpm. 346.74g (1mol) of hexachlo...

Embodiment 2

[0041] The bisphenol A cyanate ester resin prepolymer of this embodiment is composed of bisphenol A cyanate ester monomer, polymerization compatible catalyst, and composite moisture absorbent after heat preservation and stirring reaction. When the refractive index reaches 1.587, the temperature is lowered , Post-processing;

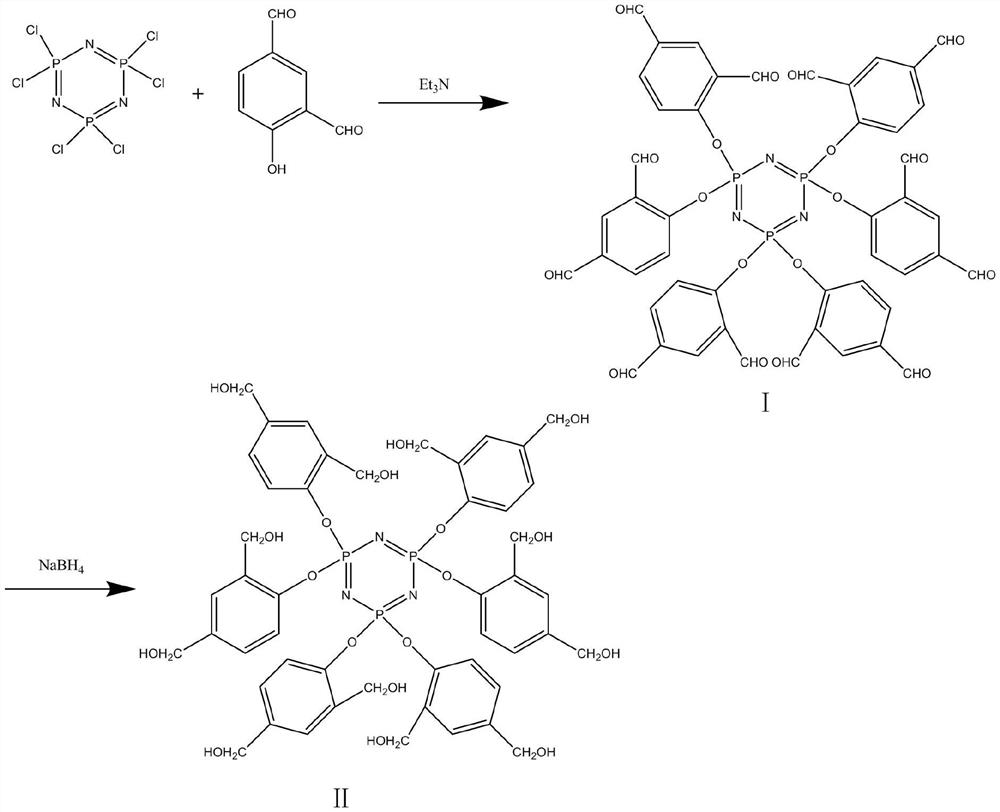

[0042] The synthesis reaction formula of the polymerization compatible catalyst is as follows:

[0043]

[0044] The composite moisture absorbent is obtained by polymerization reaction of diatomaceous earth, anhydrous magnesium sulfate and super absorbent acrylic resin under the action of a crosslinking agent and an initiator.

[0045] The preparation method of the polymerization compatible catalyst is as follows:

[0046] S1. Add 918g (6.12mol) of 4-hydroxy-1,3-phthalaldehyde, 17442g of solvent tetrahydrofuran to the reaction kettle, then add 637.50g (6.3mol) of triethylamine, raise the temperature to 69°C, stir at 500rpm, 346.74g (1mol) of hexachlorocyclotriph...

Embodiment 3

[0053] A bisphenol A cyanate ester resin prepolymer of this embodiment consists of a bisphenol A cyanate ester monomer, a polymerization compatible catalyst, and a composite hygroscopic agent through heat preservation and stirring reaction. When the refractive index reaches 1.584, the temperature is lowered , Post-processing;

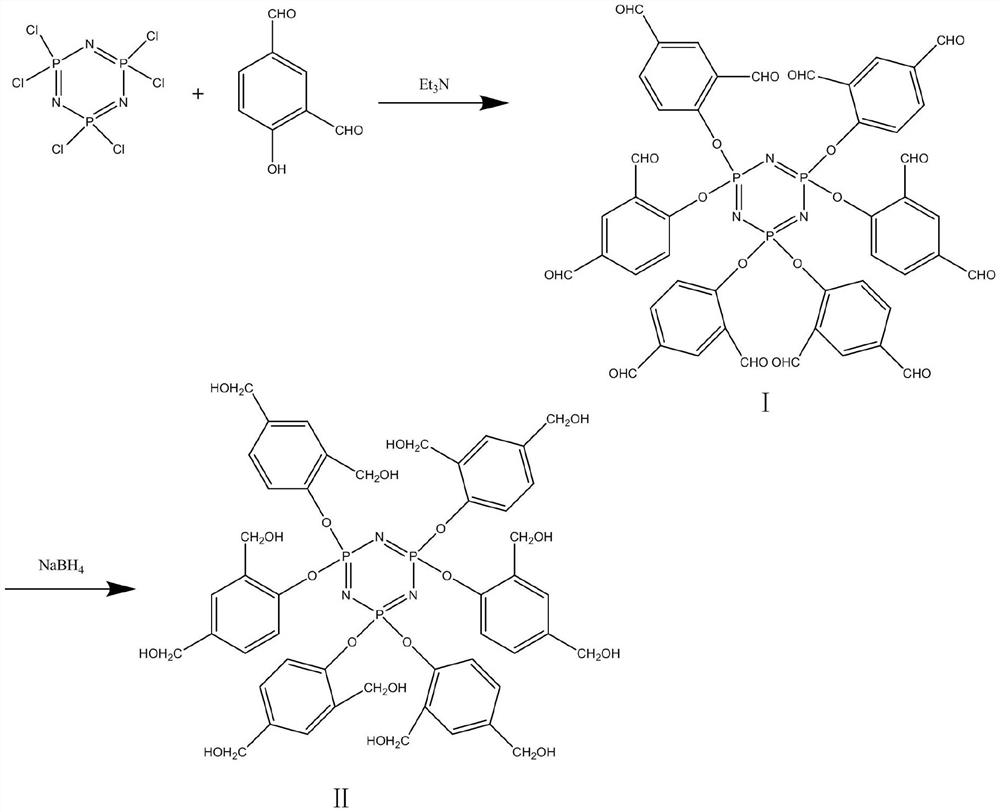

[0054] The synthesis reaction formula of the polymerization compatible catalyst is as follows:

[0055]

[0056] The composite moisture absorbent is obtained by polymerization reaction of diatomaceous earth, anhydrous magnesium sulfate and super absorbent acrylic resin under the action of a crosslinking agent and an initiator.

[0057] The preparation method of the polymerization compatible catalyst is as follows:

[0058] S1. Add 927g (6.18mol) of 4-hydroxy-1,3-phthalaldehyde, 12051g of solvent tetrahydrofuran to the reaction kettle, then add 632.44g (6.25mol) of triethylamine, raise the temperature to 69°C, stir at 490rpm, 346.74g (1mol) of hexachlorocyclotr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com