Horizontal automatic betel nut unloading equipment

An automatic unloading and horizontal technology, applied in loading/unloading, container emptying, bottle filling, etc., can solve problems such as lumbar muscle strain, site confusion, and reduced work efficiency, and achieve the goal of reducing labor intensity and workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

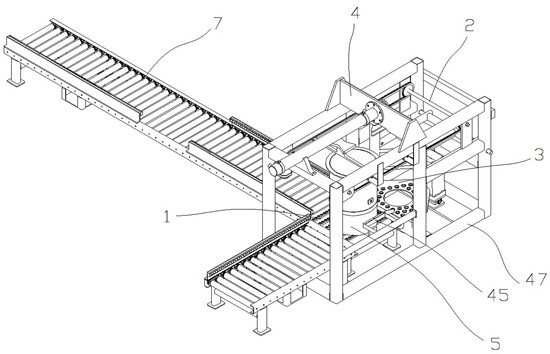

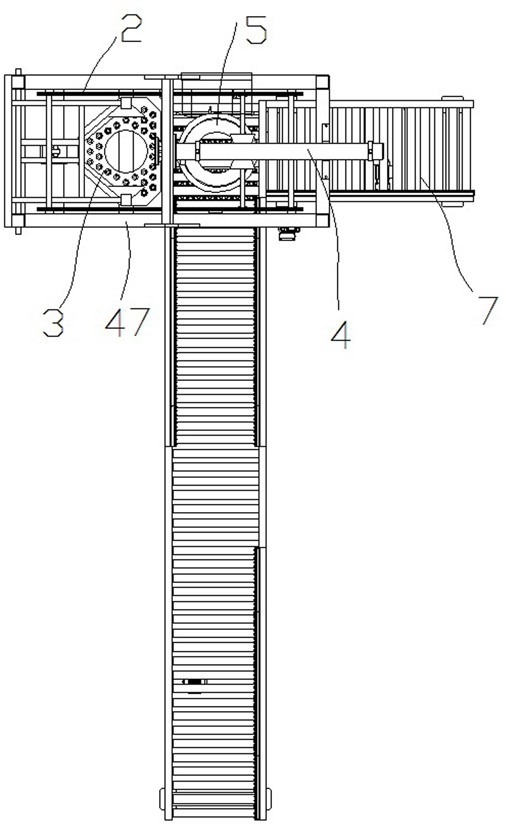

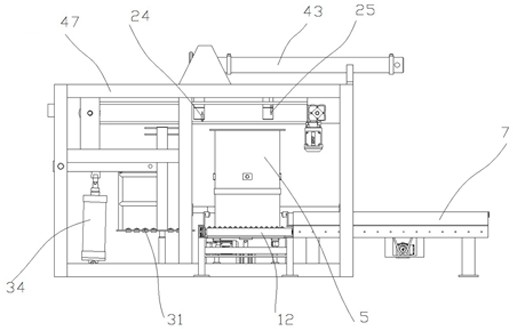

[0039] Such as Figure 1-Figure 3 As shown, a horizontal automatic betel nut unloading device of the present invention includes a conveying line 7, a jacking mechanism 1, a bucket pushing mechanism 2, a turning mechanism 3, a material pushing mechanism 4 and an electrical control system 6;

[0040] Such as Figure 4-Figure 7 As shown, the jacking mechanism 1 is located below the corner of the L-shaped conveying line 7, and it includes a support platform 12. The top surface of the support platform 12 is equipped with universal balls 11, and the bottom of the support platform 12 is respectively equipped with a guide shaft 13 and a top. Lifting cylinder 14, jacking cylinder 14 telescopically drives support platform 12 to move up and down; said support platform 12 table top is arranged with a plurality of square strips 17, and the top of square strip 17 is provided with universal ball 11, and square strip 17 is positioned at conveying line 7 in the gap between the roller 71 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com