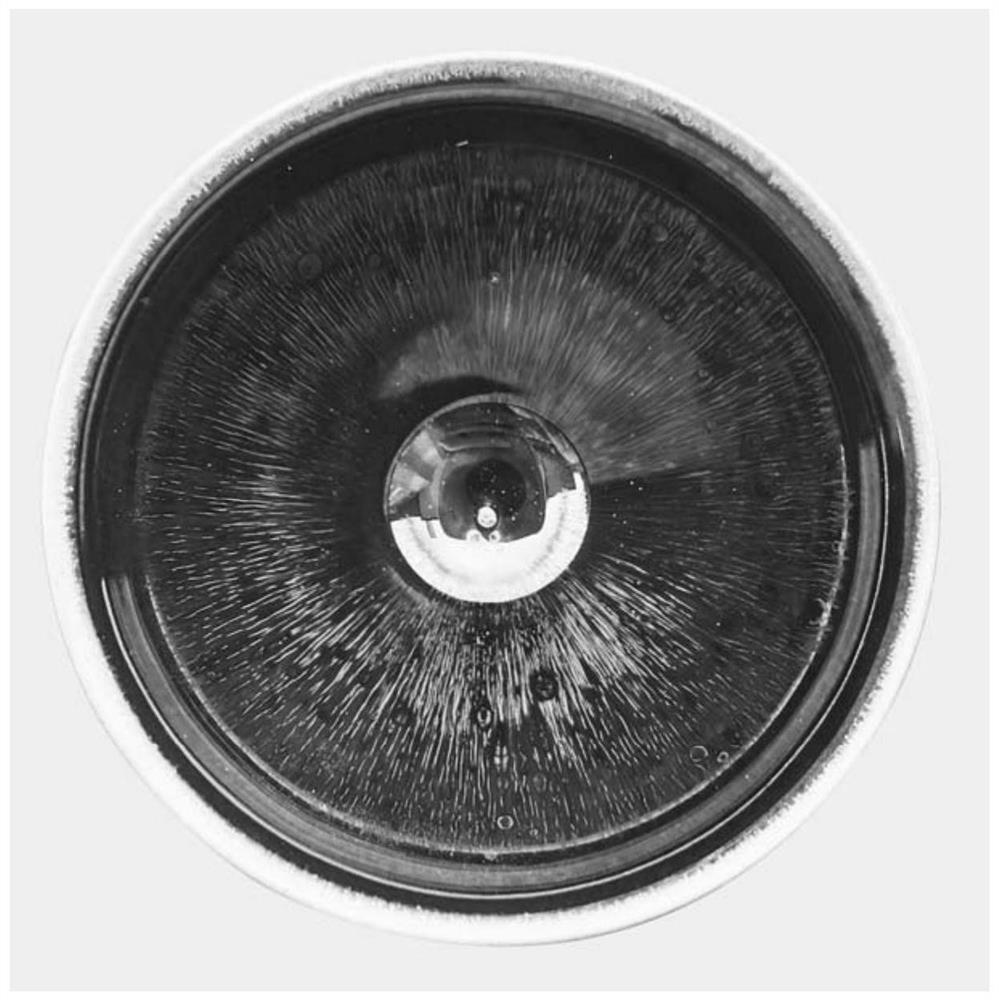

Manufacturing process of shining Jianzhan tea bowl

A kind of production process and kiln technology, applied in the field of Yaobian Jianzhan production process, can solve the problems of difficult experiment success, complex itself, and few reference materials, and achieve the effect of enriching daily life, high appreciation value, and less bubble defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Yaobian Jianzhan production process includes the following steps:

[0034] (1) preparing green body and glaze slurry;

[0035] Mix 7 parts by weight of yellow soil, 2 parts by weight of high clay and 1 part by weight of field mud, add water to wash, pass through a 100-mesh sieve, press filter, smelt, stale, pull the billet into a green body, dry it, and then trim it into a shape , dried again and bisque fired at 800°C for 7 hours to obtain the green body;

[0036] Get 100 parts by weight of red glaze ore, 50 parts by weight of water, 11 parts by weight of plant ash, 13 parts by weight of potassium feldspar powder, 9 parts by weight of quartz powder, 8 parts by weight of talcum powder, 4 parts by weight of iron red and 1 part by weight of aluminum powder; The red glaze ore is crushed and ground to a particle size of 100 mesh, and stale for 7 days; plant ash, potassium feldspar powder, quartz powder, talc powder, iron red, and aluminum powder are all ground to a particle...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is:

[0049] Step (1) preparing green body and glaze slurry;

[0050] Mix 7 parts by weight of yellow soil, 2 parts by weight of high clay and 1 part by weight of field mud, add water to wash, pass through a 110-mesh sieve, press filter, smelt, stale, pull the blank into a green body, dry it, and then trim it into a shape , dried again and bisque fired at a temperature of 850°C for 6 hours to obtain a green body;

[0051] Get 100 parts by weight of red glaze ore, 48 parts by weight of water, 12 parts by weight of plant ash, 15 parts by weight of potassium feldspar powder, 8 parts by weight of quartz powder, 6 parts by weight of talcum powder, 5 parts by weight of iron red and 1 part by weight of aluminum powder; The red glaze ore is crushed and ground to a particle size of 80 mesh, and stale for 6 days; plant ash, potassium feldspar powder, quartz powder, talc powder, iron red, and aluminum powder are all ground to a...

Embodiment 3

[0054]The difference between embodiment 3 and embodiment 1 is:

[0055] Step (1) preparing green body and glaze slurry;

[0056] Mix 7 parts by weight of yellow soil, 2 parts by weight of high clay and 1 part by weight of field mud, add water to wash, pass through a 100-mesh sieve, press filter, smelt, stale, pull the billet into a green body, dry it, and then trim it into a shape , after drying again, biscuit firing, bisque firing temperature 820 ° C, firing for 8 hours, to obtain the green body;

[0057] Get 100 parts by weight of red glaze ore, 52 parts by weight of water, 10 parts by weight of plant ash, 12 parts by weight of potassium feldspar powder, 10 parts by weight of quartz powder, 7 parts by weight of talcum powder, 3 parts by weight of iron red and 2 parts by weight of aluminum powder; The red glaze ore is crushed and ground to a particle size of 90 mesh, and stale for 5 days; plant ash, potassium feldspar powder, quartz powder, talc powder, iron red, and aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com