Application of silver phosphate as PET-RAFT controllable polymerization effective photocatalyst

A photocatalyst, silver phosphate technology, applied in the field of photocatalysis and polymer, to achieve the effect of good time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

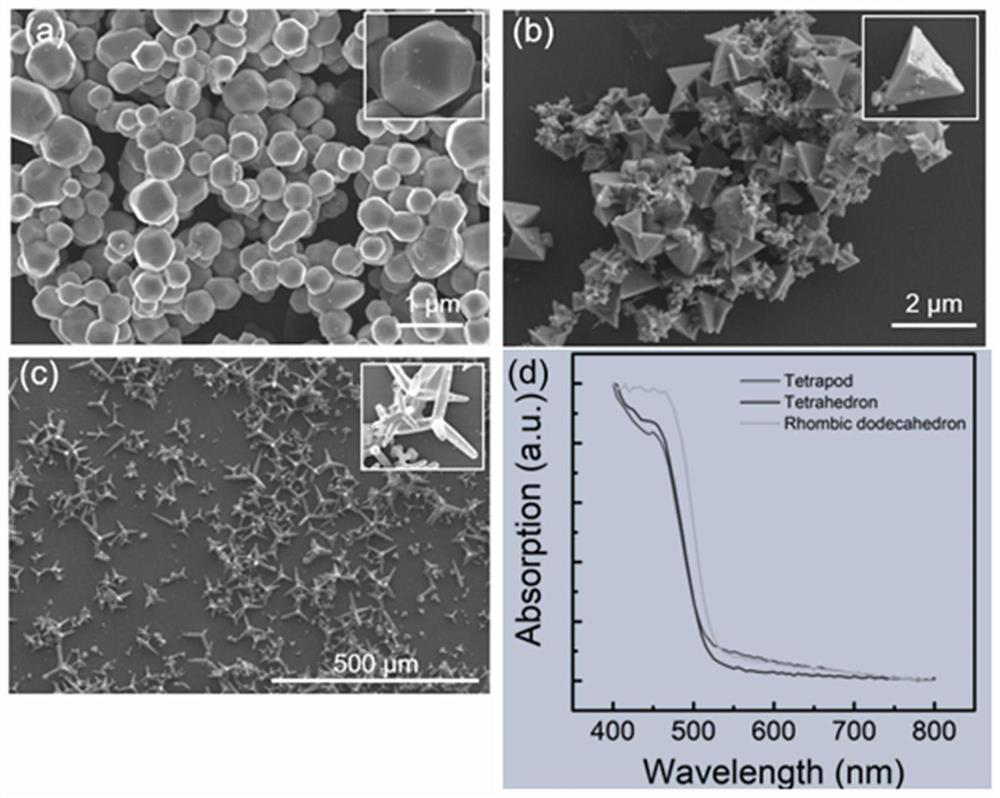

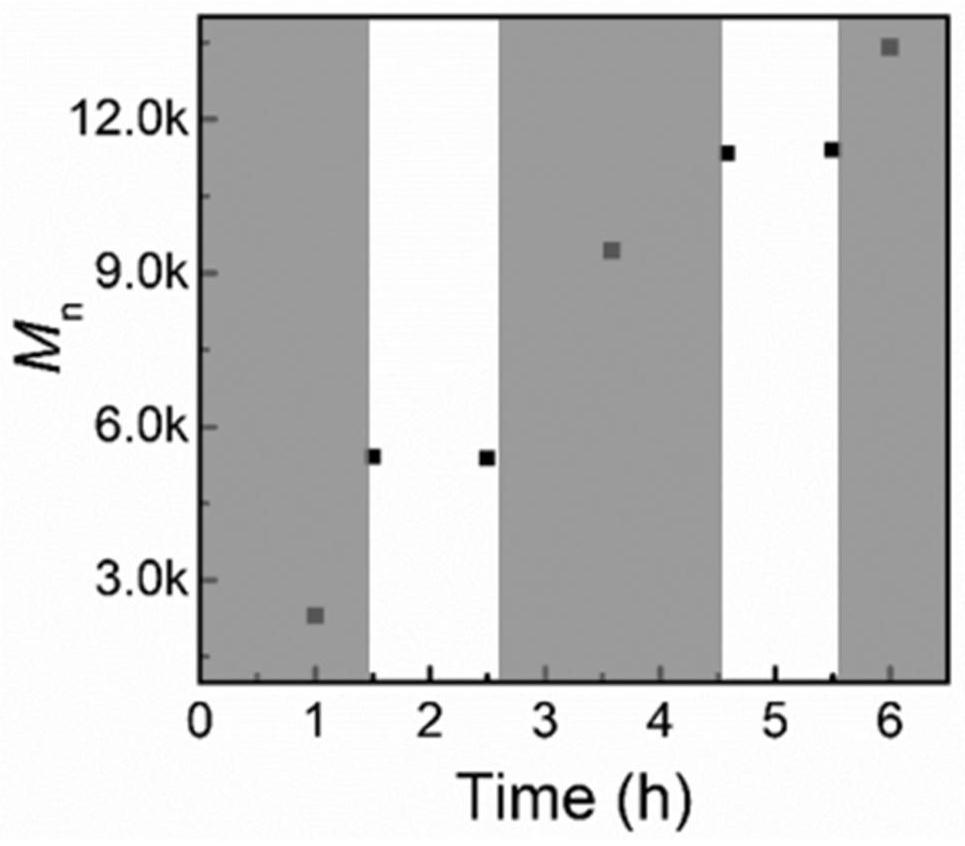

[0028] Take 5 mg rhombohedral dodecahedral silver phosphate, 11.2 mg BTPA, 549 μL methyl acrylate and 1 mL dimethyl sulfoxide, add them to a 10 mL quartz reaction bottle and seal them, use the bubbling method to remove the air in the reaction system, and then put the reaction bottle Into the photoreactor, at 2 mW / cm 2 Under blue light irradiation, the reaction was carried out for 3.7 hours. The conversion rate was 76.5%, the theoretical molecular weight was 8560, the measured molecular weight was 10560, and the molecular weight distribution D was 1.10.

Embodiment 2

[0030] Take 5mg of tetrahedral silver phosphate, 11.2mg of BTPA, 549μL of methyl acrylate and 1mL of dimethyl sulfoxide and add them into a 10mL quartz reaction vial to seal it. Use the bubbling method to remove the air in the reaction system, and then put the reaction vial into the light. In the reactor, at 2mW / cm 2 Under blue light irradiation, the reaction was carried out for 3.7 hours. The conversion rate was 82.6%, the theoretical molecular weight was 9240, the measured molecular weight was 13120, and the molecular weight distribution D was 1.12.

Embodiment 3

[0032] Take 5mg of tetrapod-like silver phosphate, 11.2mg of BTPA, 549μL of methyl acrylate and 1mL of dimethyl sulfoxide, put them into a 10mL quartz reaction bottle and seal it, use the bubbling method to remove the air in the reaction system, and then put the reaction bottle into the light In the reactor, at 2mW / cm 2 Under blue light irradiation, the reaction was carried out for 3.7 hours. The conversion rate was 69.1%, the theoretical molecular weight was 7730, the measured molecular weight was 9200, and the molecular weight distribution D was 1.12.

[0033] figure 1 The morphology (rhombic dodecahedron, tetrahedron, tetrapod) and its ultraviolet-visible diffuse reflectance spectrum of silver phosphate used in Examples 1 to 3 are shown. The catalytic effects of silver phosphate were compared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com