Micro-surfacing emulsified asphalt suitable for low-temperature construction at night as well as preparation method and application thereof

An emulsified asphalt and micro-surface technology, which is applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of slow demulsification, long curing time, and low temperature at night at the micro-surface, so as to improve anti-skid and anti-skid. The effect of water seepage performance, shortened construction period and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

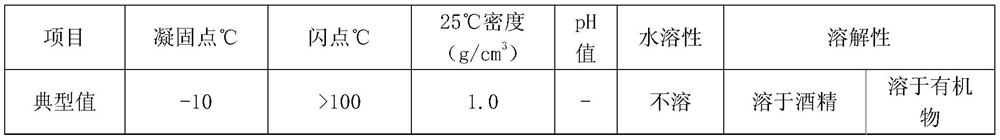

Image

Examples

Embodiment 1

[0048] A preparation method for micro-surface emulsified asphalt suitable for nighttime low-temperature construction conditions. The mass components of each raw material are: 50 parts of petroleum asphalt, 1 part of emulsifier, 40 parts of water, 2 parts of warm mixing agent, and 2 parts of modified latex parts, 3 parts of additives. A kind of micro-surfacing mixture for paving, the specific implementation process comprises the following steps:

[0049] (1) Heat the 90# petroleum asphalt to 160°C, add Cecabase RT surfactant-type warm mix agent, and mix and stir for 3 minutes;

[0050] (2) Add MQK-3 cationic emulsifier into water to prepare an aqueous solution, then add SBR modified latex, then heat the prepared soap to 65°C, and finally adjust the pH of the soap to 2.5 with acid;

[0051] (3) Quickly pour the soap liquid into the colloid mill of the emulsifier for shearing, and then pour the hot-melt asphalt and rock asphalt additives stirred in step (1) into the shearing soa...

Embodiment 2

[0060] A kind of micro-surface emulsified asphalt suitable for low-temperature construction at night. The mass components of each raw material are: 52 parts of petroleum asphalt, 2 parts of emulsifier, 35 parts of water, 4 parts of warm mixing agent, 3 parts of modified latex, Additive 2 parts.

[0061] The specific implementation process is basically the same as that of Example 1, the difference is that the quality components of each raw material are slightly different, and in step 4, 2 parts of inorganic filler, 10 parts of emulsified asphalt and 95 parts by weight of aggregate are mixed and stirred.

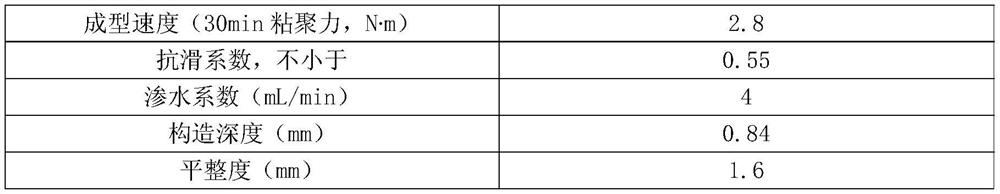

[0062] In order to verify the effect of this patent, the low-temperature micro-surfacing mixed material in the proportion of Example 2 was used for actual paving, and the test was carried out according to E20 of the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering". The test results are shown in Table 2:

[0063] Table 2 Performance test indicators of ...

Embodiment 3

[0067] A micro-surfacing emulsified asphalt suitable for low-temperature construction at night. The mass components of each raw material are: 50 parts of petroleum asphalt, 5 parts of emulsifier, 40 parts of water, and 5 parts of modified latex.

[0068] The specific implementation process is basically the same as in Example 1, the difference being that the amount of emulsifier and modified latex added is slightly different, no warm mixing agent is added in the step (1), and no inorganic filler is added in the step (4).

[0069] In order to verify the effect of this patent, the low-temperature micro-surfacing mixture in the proportion of Example 3 was used for actual paving, and the test was carried out according to E20 of the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering". The test results are shown in Table 3:

[0070] Table 3 Performance test index of mixture at low temperature microsurfacing

[0071] Test items results of testing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com