A method for automatic separation of spindles for mule spinning

An automatic separation and spindle technology, applied in textiles and papermaking, etc., can solve problems such as inconvenient use, achieve the effects of reducing time-consuming processes, keeping clean, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

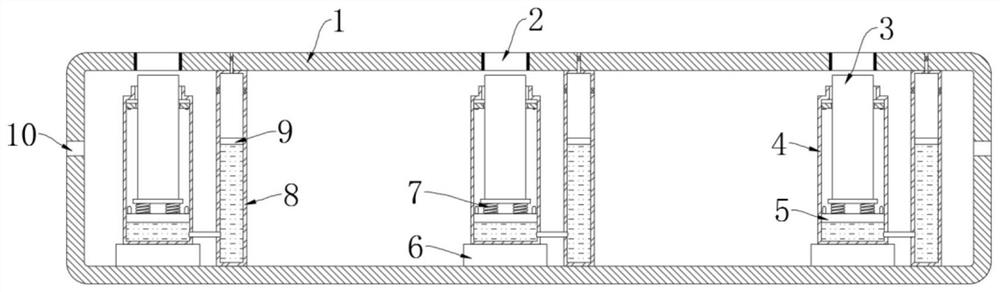

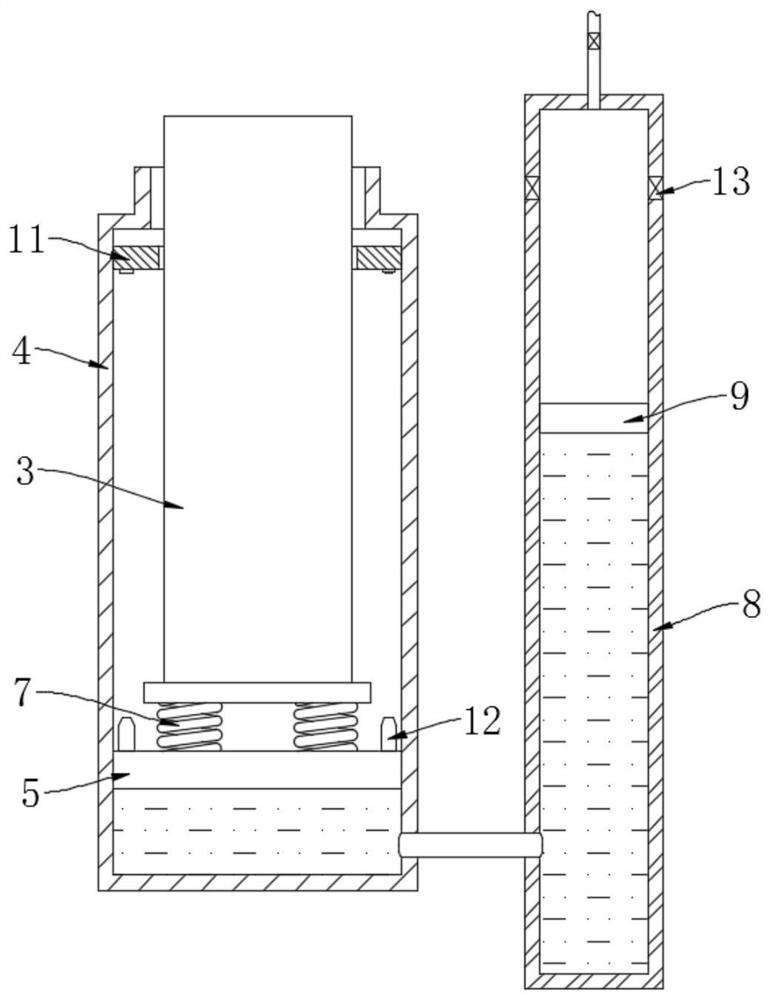

[0031] refer to Figure 1-5 , a method for automatic separation of spindles for mule spinning, the specific method of use is as follows:

[0032] S1. Conveying the spinning bobbin: place the spinning bobbin in the fixed box 14, open the drive mechanism, make the driving mechanism drive the conveyor belt to run, transfer the fixed box 14 to the top of the magnetic isolation box 1, and the circular groove and the ring Opening 2 is opposite;

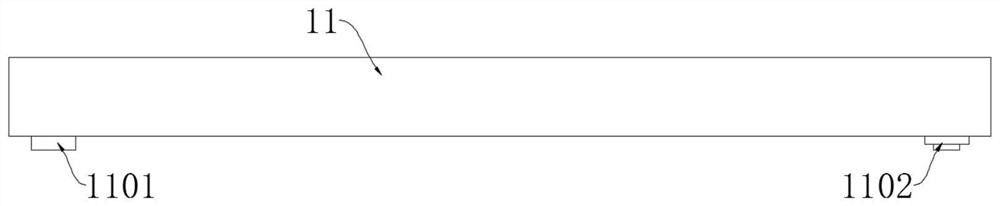

[0033] S2. Fixing the spinning bobbin: supplying power to the magnetic field generator 6 to excite the magnetic field. Under the repulsion of the magnetic field, the first sealing plate 5 moves upward until the two trigger keys 12 are connected to the first delay switch 1101 and the second delay switch 1101 respectively. The delay switch 1102 offsets, and the spinning bobbin is sleeved on the spindle 3 at this time;

[0034] S3, yarn covering: open the yarn covering mechanism 17, so that the yarn is covered on the outside of the spinning ...

Embodiment 2

[0050] refer to Figure 6 , the present embodiment differs from Embodiment 1 in that: each annular opening 2 is fixedly installed with a heightening baffle 18, the upper surface of the magnetic isolation box 1 is provided with a plurality of hollow redirection plates 19, and each sealing cylinder 8 The upper ends of each are connected to the corresponding hollow redirecting plate 19 through a straight pipe, and the plane where the top of the hollow redirecting plate 19 is located is located below the plane where the top of the heightening baffle 18 is located;

[0051] The hollow redirecting plate 19 is in the shape of a raised arc, and its side wall is provided with a plurality of air outlets in the circumferential direction. After the air flows from the sealed cylinder 8 to the hollow redirecting plate 19, it can only be discharged outward through the air outlets, thereby forming a radiant atmosphere. airflow.

[0052] When this embodiment is working, there will be thread e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com