Washing machine

A washing machine and laundry bin technology, applied in the field of washing machines, can solve the problems of damaged clothes and difficult to remove stains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

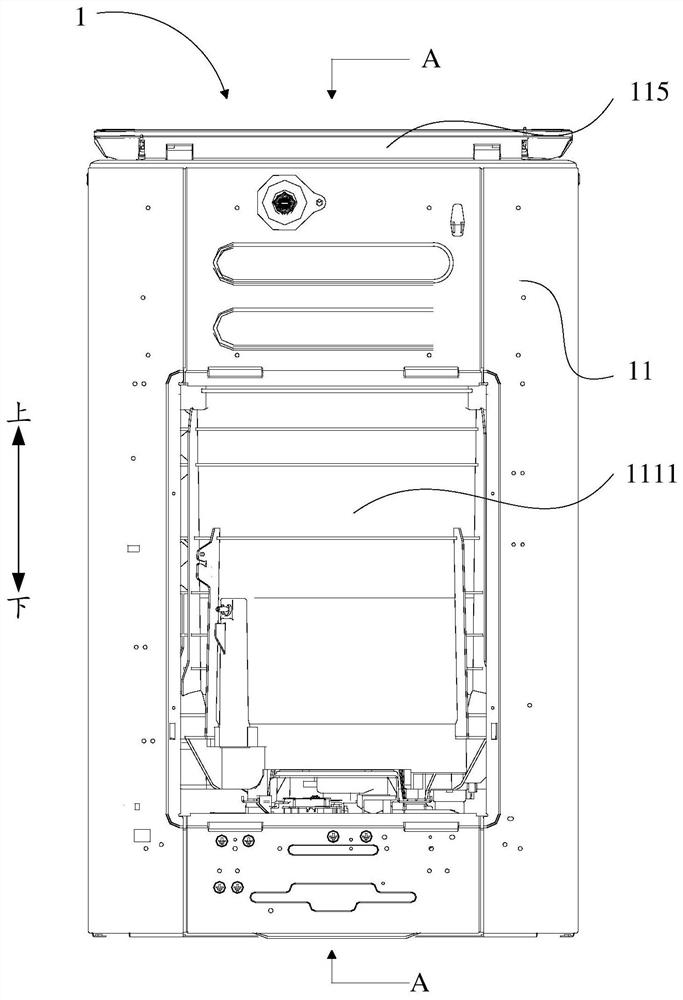

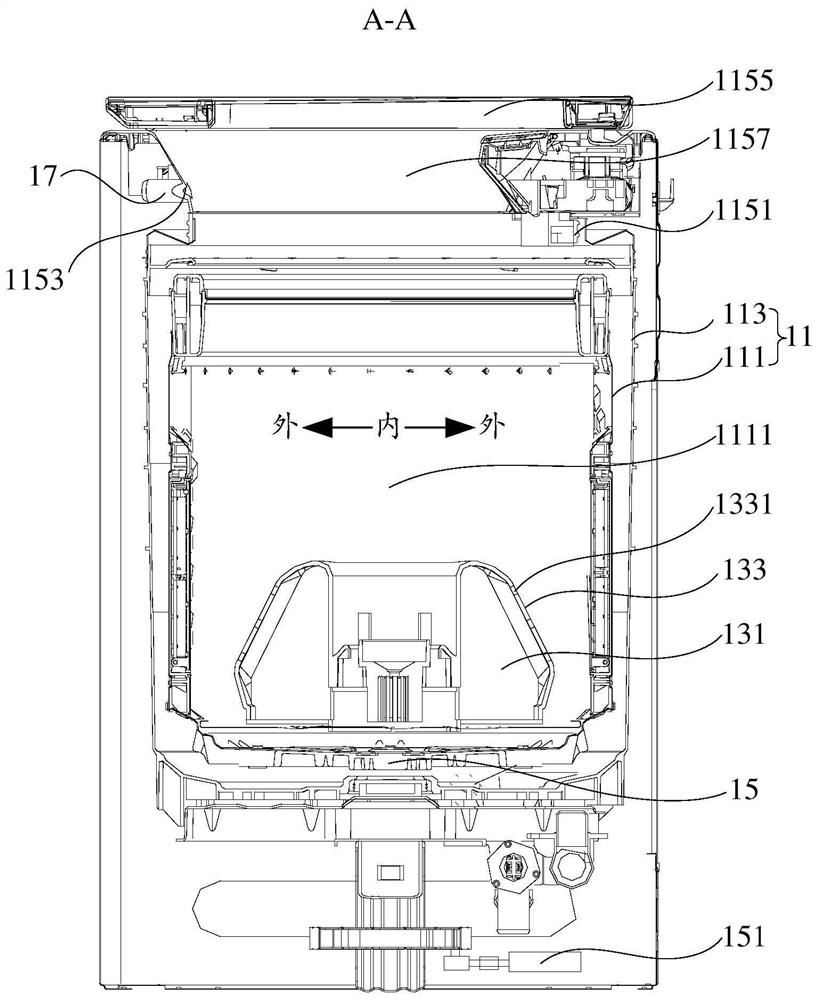

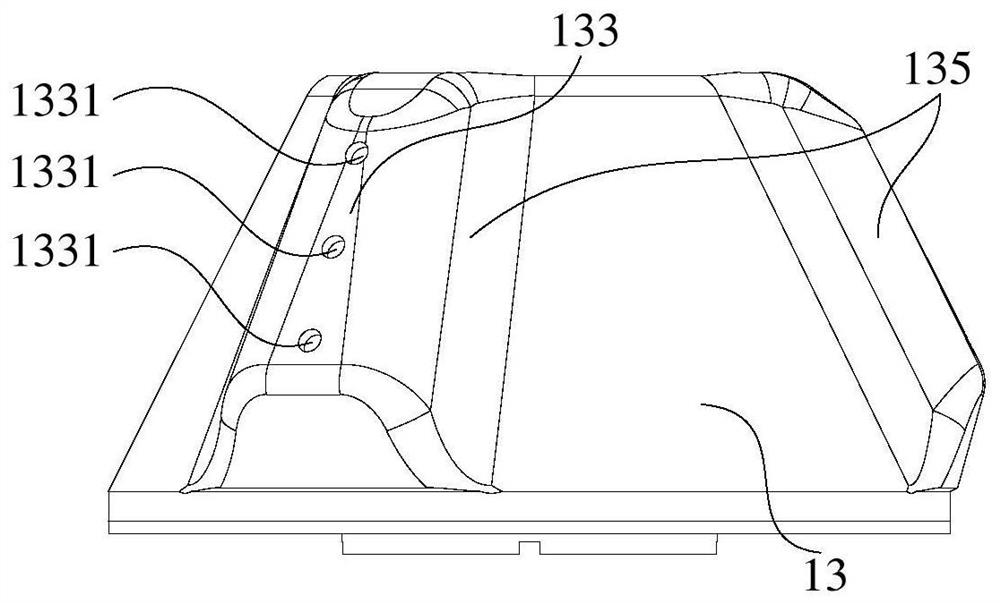

[0063] The barrel part 11 is provided with a laundry compartment 1111, such as figure 1 Shown; The water flow forming member 13 is located in the laundry compartment 1111, as figure 2 , Image 6 with Figure 7As shown, the water-air flow forming member 13 is provided with a water-air mixing chamber 131, and the water-air mixing chamber 131 has an air inlet and an inlet and outlet 1331 connected to the laundry compartment 1111; the air intake system 15 includes an air source 151 connected to the air inlet ,Such as figure 2 , Image 6 with Figure 7 As shown, it is used to supply air to the water-air mixing chamber 131, so that the water-air mixing chamber 131 delivers water flow to the laundry compartment 1111, so that the clothes in the laundry compartment 1111 can be washed by the water flow.

[0064] The washing machine 1 provided by the present invention is provided with an air intake system 15 and a water-air flow forming part 13, and the water-air mixing chamber 13...

Embodiment 2

[0075] Embodiment 2 (not shown in the figure)

[0076] The difference from Embodiment 1 is that the slope 133 surrounds the laundry chamber 1111 in the circumferential direction to form an annular slope 133 , there are multiple entrances and exits 1331 , and the multiple entrances and exits 1331 are evenly distributed along the circumferential direction of the slope 133 .

[0077] The inclined surface 133 is designed as an annular inclined surface 133, and the annular inclined surface 133 surrounds the circumferential direction of the laundry bin 1111, and a plurality of inlets and outlets 1331 are evenly arranged on the annular inclined surface 133, and the water vapor flow ejected from the plurality of inlets and outlets 1331 can also affect the laundry bin 1111. Clothes in different positions in the circumferential direction play an impact role, and the clothes in different positions in the circumferential direction of the laundry compartment 1111 can drive the movement of t...

Embodiment 3

[0079] The difference from any of the above-mentioned embodiments is that: on the basis of any of the above-mentioned embodiments, further, there are multiple inlets and outlets 1331, and the multiple inlets and outlets 1331 are distributed at intervals along the height direction of the water flow forming member 13, such as figure 2 , image 3 with Figure 5 shown.

[0080] Further, a plurality of inlets and outlets 1331 are arranged in multiple layers along the height direction of the water flow forming member 13 .

[0081] The number of inlets and outlets 1331 is multiple, which can generate multiple water vapor flows, and different water vapor flows impact different parts of the clothes to achieve the effect of fully washing the clothes; multiple inlets and outlets 1331 are arranged at intervals along the height direction of the water flow forming member 13 It is multi-layered, which can generate multi-layer water flow, which can impact the clothes of different heights i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com