Handheld building material mounting device

A technology for installing devices and building materials, applied in the processing of building materials, construction, building components, etc., can solve problems such as increasing work difficulty, threatening life safety, and low efficiency, so as to reduce production safety hazards, strengthen structural stability, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

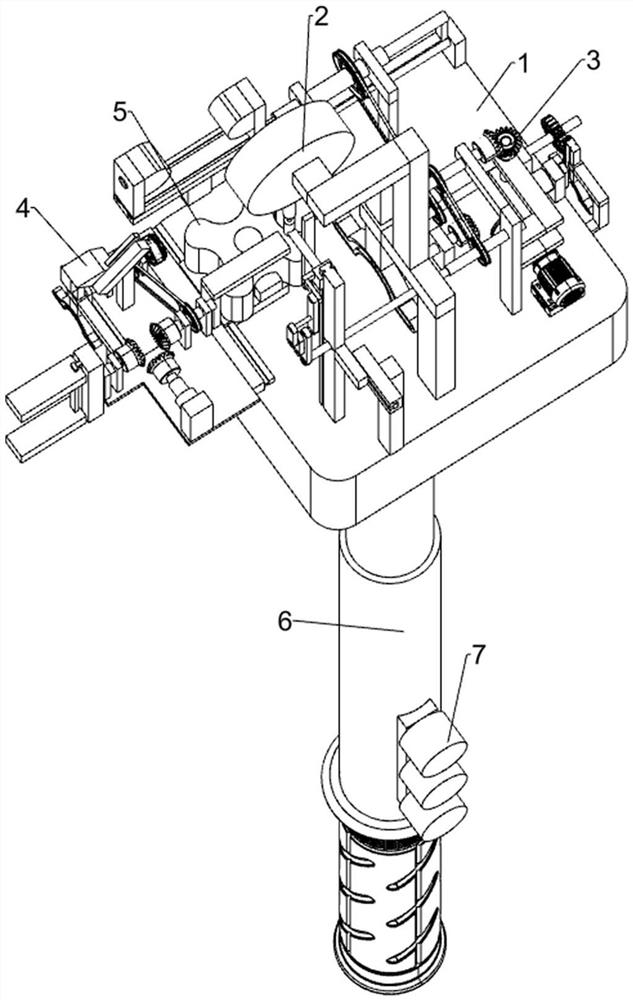

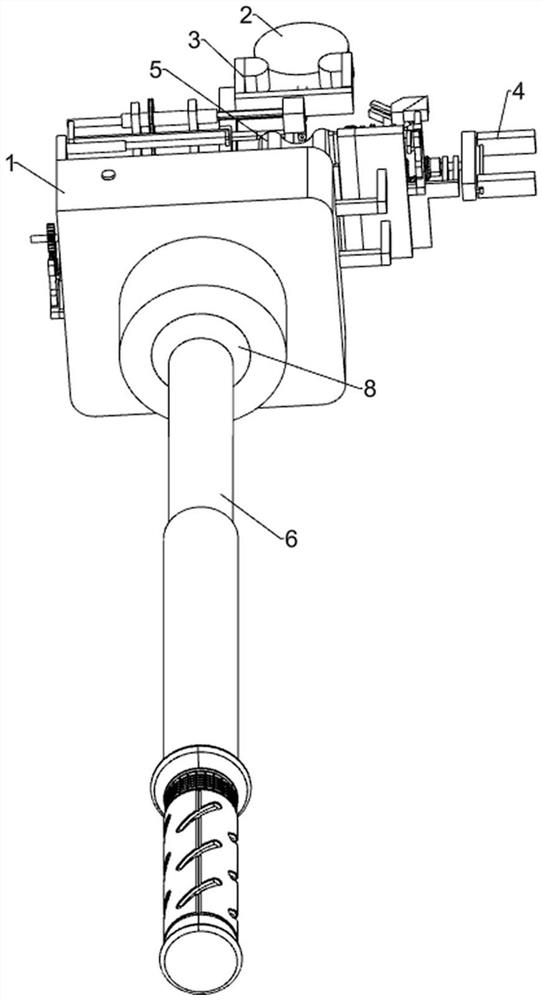

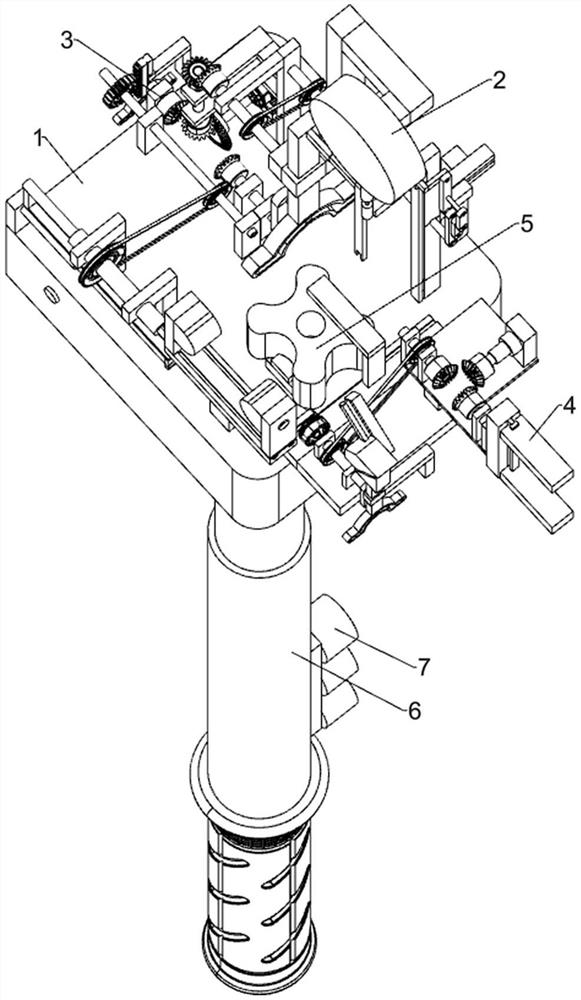

[0029] A hand-held building material installation device, such as Figure 1-8 As shown, it includes a first underframe 1, a double-layer wire threading mechanism 2, a steel pad rotation insertion mechanism 3, a wire tightening mechanism 4, a reinforced concrete pad 5, a first electric telescopic rod 6, a control switch 7 and an electric cardan shaft 8. A wire tightening mechanism 4, a reinforced cement pad 5, a double-layer wire threading mechanism 2 and a steel pad rotation insertion mechanism 3 are arranged above the first chassis 1 in sequence; the bottom of the first chassis 1 is connected with the electric universal shaft 8; One side of the double-layer wire-threading mechanism 2 is provided with a steel bar pad rotation insertion mechanism 3, and the other side of the double-layer wire-threading mechanism 2 is provided with a wire tightening mechanism 4; the double-layer wire-threading mechanism 2 is connected with the reinforced concrete pad 5; The electric cardan shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com