Wind-driven generator tower drum and tower footing yawing type wind-driven generator unit with same

A technology for wind turbines and wind turbines is applied in the control of wind turbines, wind turbines that are consistent with the wind direction, wind turbines and other directions, and can solve problems such as waste of tower manufacturing materials and reduced power generation performance of wind turbines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific examples.

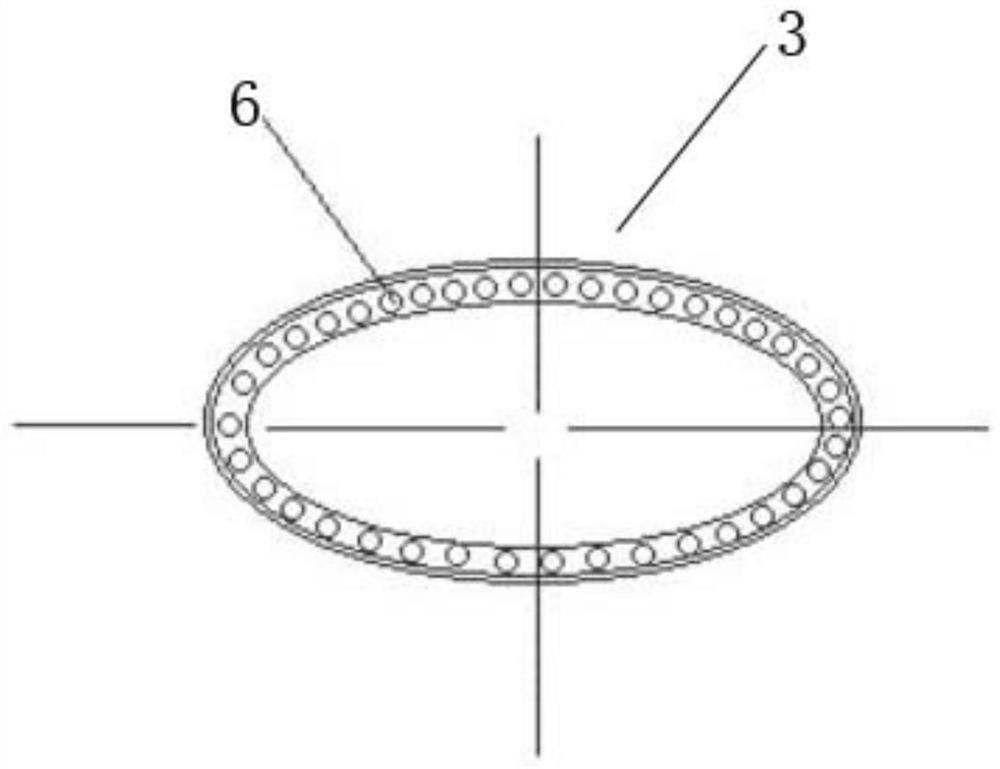

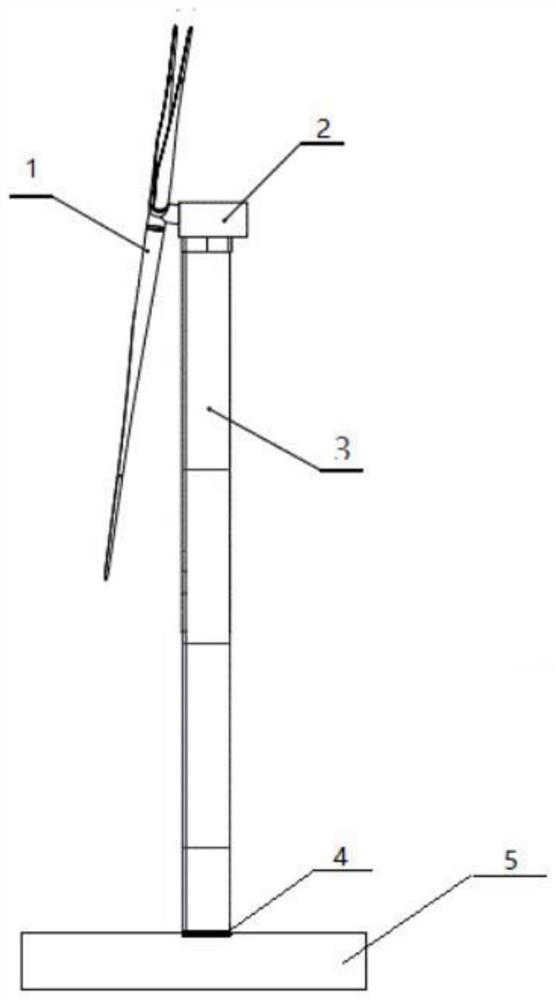

[0013] Such as figure 1 , figure 2 As shown, the wind power generator tower described in this embodiment and the tower-based yaw-type wind turbine with it, the tower-base yaw-type wind turbine includes an impeller system 1, a nacelle system 2, and a tower 3 , a yaw system 4, a foundation 5 and a connecting bolt 6, the impeller system 1 is installed on the nacelle system 2, the nacelle system 2 is fixedly installed on the top of the tower 3, and the bottom of the tower 3 passes through the yaw system 4 Transitionally installed on the foundation 5, the impeller system 1, the nacelle system 2 and the tower 3 can rotate around the central axis of the tower 3 as a whole when the unit yaws against the wind. At this time, the tower 3 bears the main external load (bending The direction of the moment load) is relatively fixed relative to the nacelle 2, so the cross-section of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com