An embedded heat dissipation structure led corn lamp

A technology of LED corn light and heat dissipation structure, which is applied in the direction of cooling/heating devices with built-in power supply, lighting and heating equipment, lighting devices, etc., can solve the problems of large energy waste, affecting the use of lights, power outages, etc., and achieve Heat dissipation control, improved maintenance performance, accurate and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

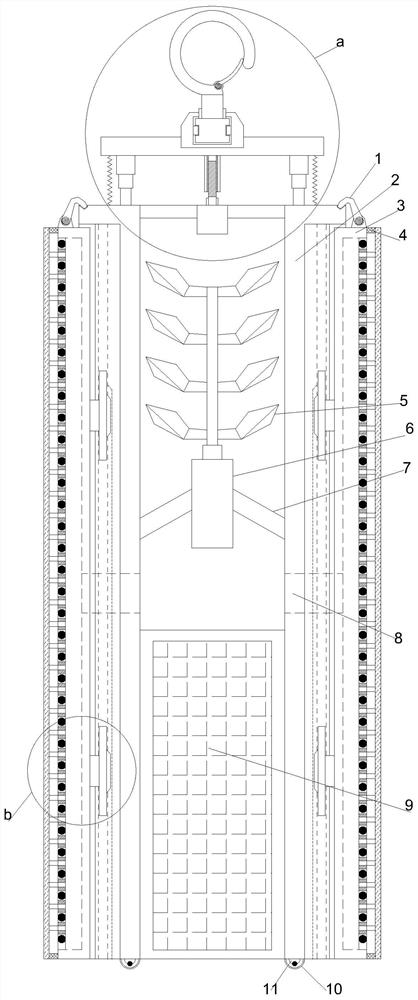

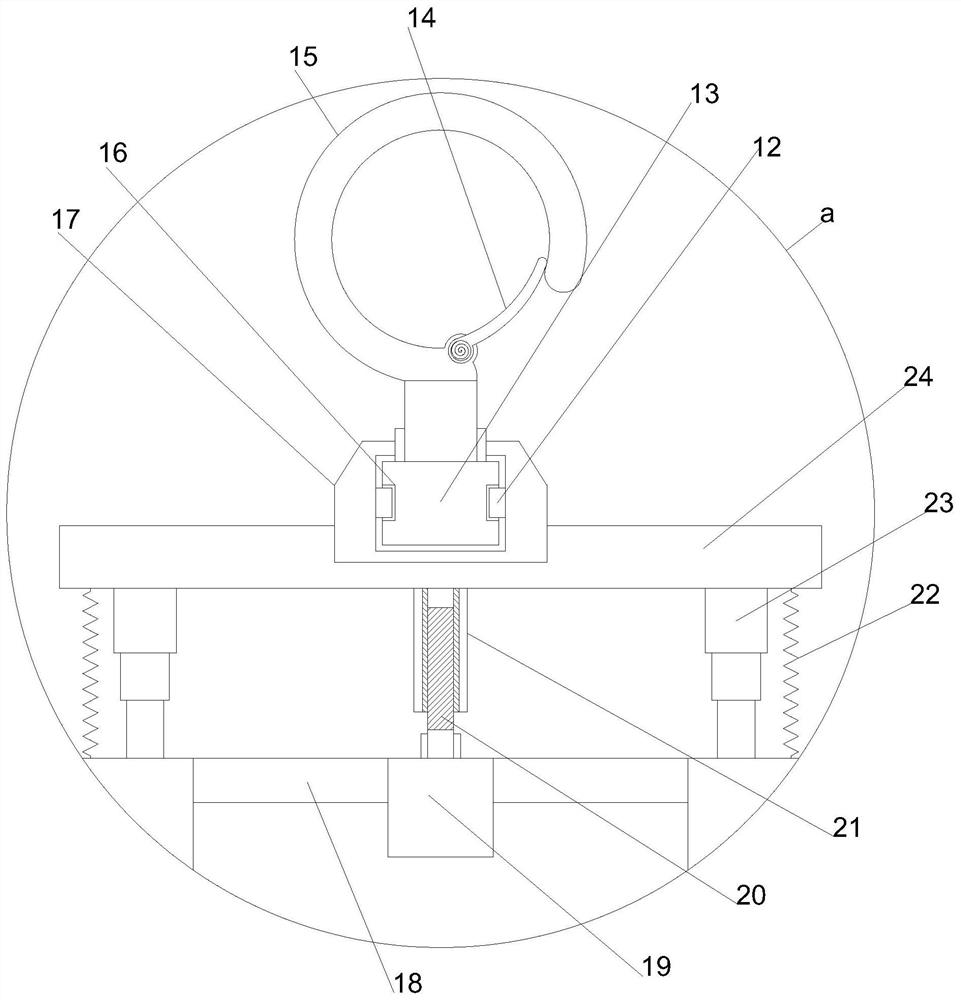

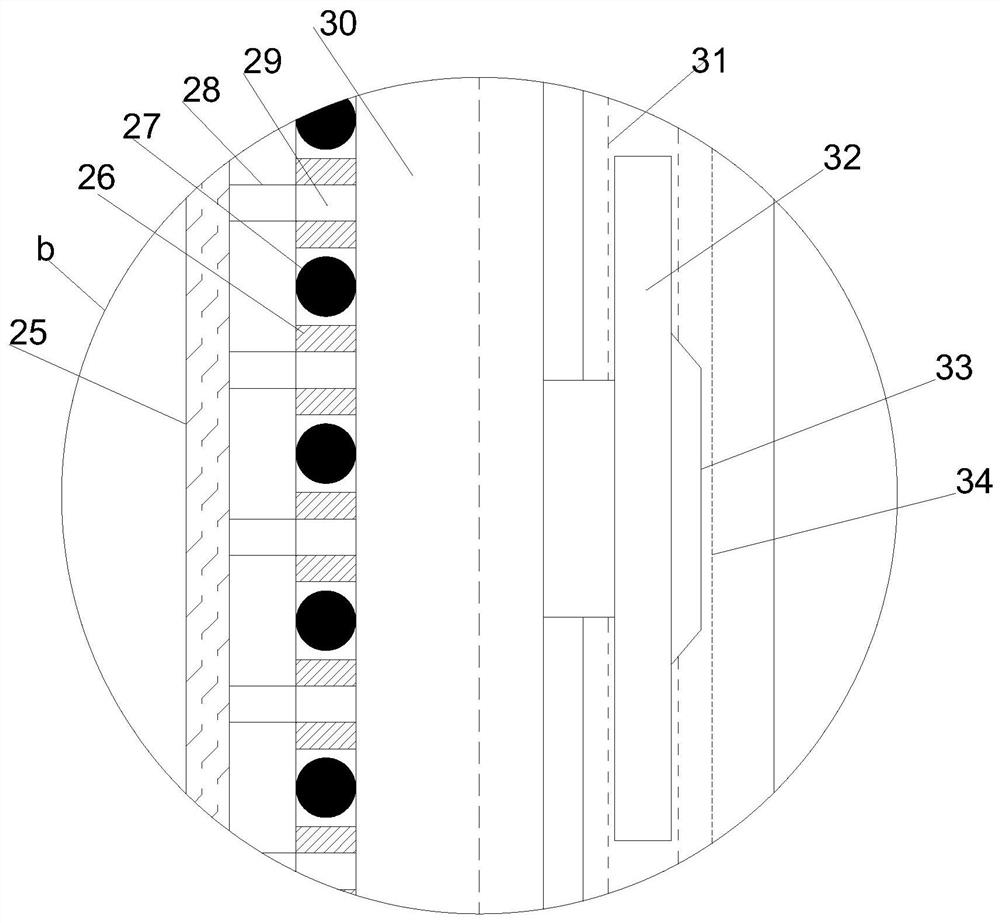

[0022] see Figure 1~4 , in an embodiment of the present invention, an LED corn lamp with an embedded heat dissipation structure includes a vertically arranged support installation cylinder 2, a support installation plate 24 is horizontally arranged directly above the support installation cylinder 2, and the middle of the upper end of the support installation plate 24 The limit rotation sleeve 17 is arranged vertically at the position, and the limit rotation column 13 is vertically arranged with the limit rotation sleeve 17. The inboard of the limit rotation sleeve 17 is horizontally provided with a conductive ring 12, and the outside of the limit rotation column 13 cooperates with the conductive ring 12. A ring-shaped conductive groove 16 is provided, a hook 15 is provided at the upper end of the limit rotation column 13, and a reset rotation plate 14 is provided at the lower end of the hook 15 through a reset rotating shaft, and several guiding telescopic columns are arranged...

Embodiment 2

[0025] On the basis of Embodiment 1, the fixing of the hook 15 is stabilized by resetting the rotating plate 14 to prevent its decoupling. By adjusting the motor 19, the displacement shaft is rotated with the displacement screw cylinder 21 to realize the support installation plate 24 and the support installation cylinder. The distance between 2 is adjusted. At this time, the guide telescopic column 23 makes the adjustment of the device stable, changes the air flow rate, and adjusts the heat dissipation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com