Device and method for simulating corrosion fatigue test in marine atmospheric environment

A corrosion fatigue, marine and atmospheric technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as inability to evaluate metal corrosion fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

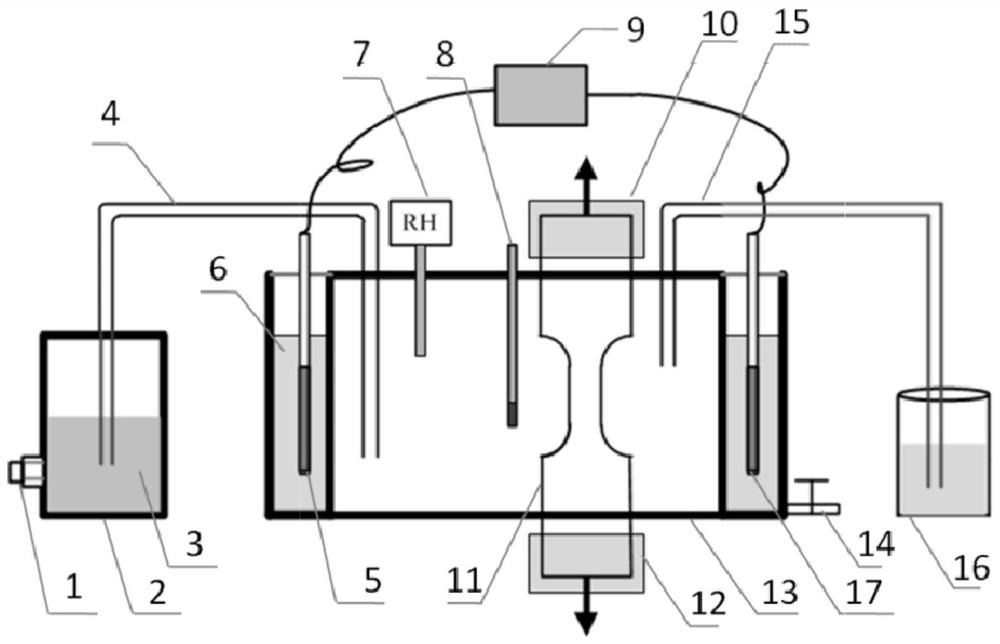

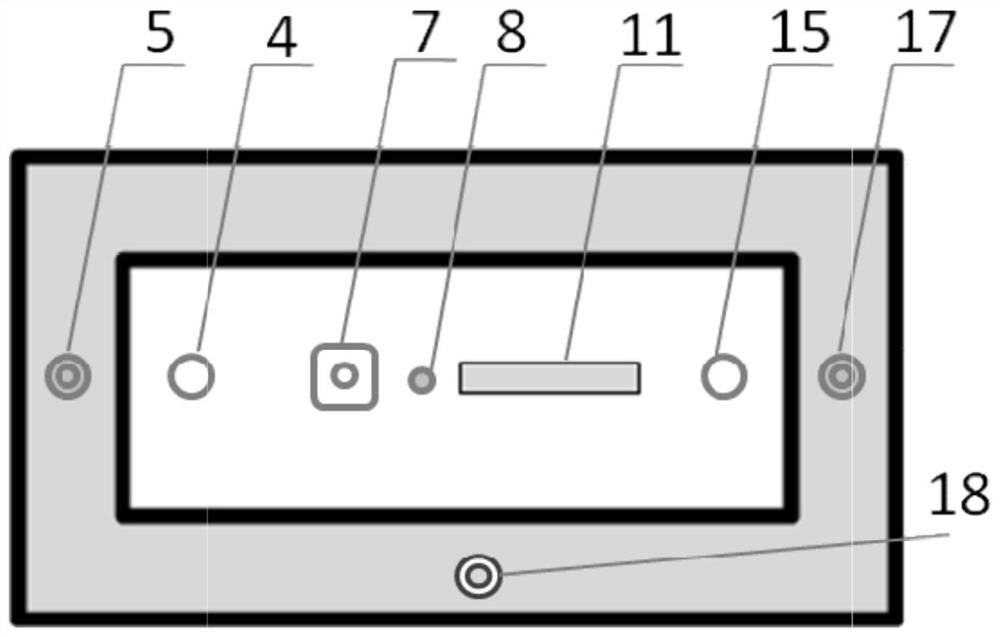

[0021] Below, combined with figure 1 , figure 2 And embodiment the present invention is described in further detail.

[0022] Specifically, when the present embodiment adopts the corrosion fatigue test device in the simulated marine atmosphere environment for the test, the fatigue sample 11 is first processed by wire cutting, and the sample 11 can be processed by the national standard or related standards. Then the processed sample 11 was processed, polished to 2000# step by step with SiC sandpaper, degreased with acetone, cleaned with absolute ethanol, and then dried for use. The two ends of the sample 11 were sealed with silica gel, and only the middle 10 was exposed. Working section with a length of ~20mm.

[0023] Install the sealed fatigue sample 11 in the test chamber 13 with cuboid structure made of plexiglass through a soft rubber stopper, and use silica gel to seal the sample 11 and the rubber stopper and the through hole between the rubber stopper and the test cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com