Passive electronic voltage sensor and manufacturing method thereof

A voltage sensor, electronic technology, applied in the direction of measuring current/voltage, measuring only voltage, instruments, etc., can solve the problems of large size of the voltage sensor, inconvenient installation, etc., to ensure the electrical insulation performance, improve the withstand voltage performance, measurement wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

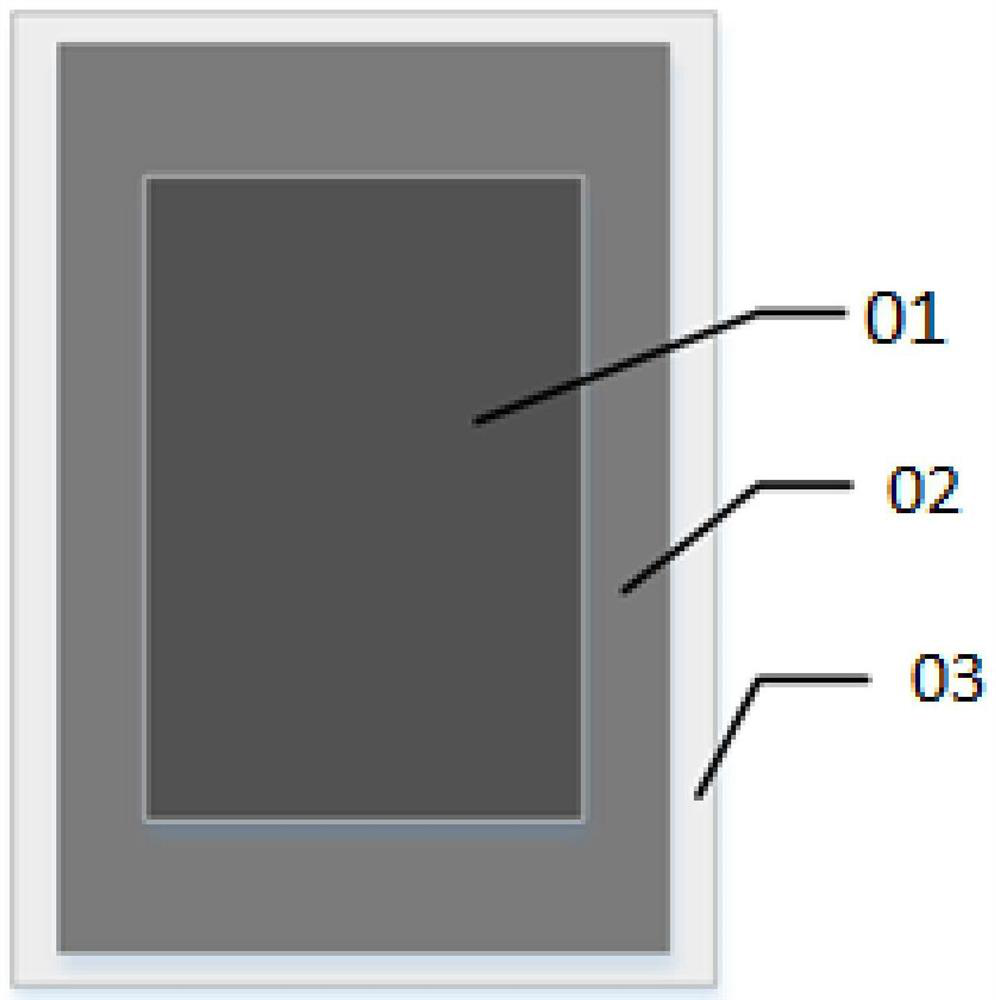

[0031] Such as figure 1 As shown, a passive electronic voltage sensor provided by an embodiment of the present invention includes a film capacitor 01 and a potting body, and the potting body includes an inner potting body 02 and an outer potting body 03 . The film capacitor 01 is arranged inside the inner casting body 02 , and the outer casting body 03 is arranged outside the inner casting body 03 .

[0032] The passive electronic voltage sensor provided by the embodiment of the present invention encapsulates the film capacitor through a layered casting body, which can solve the problems of existing sensors such as air bubbles, cracks and partial discharge, and can ensure the electrical insulation performance of the passive electronic sensor.

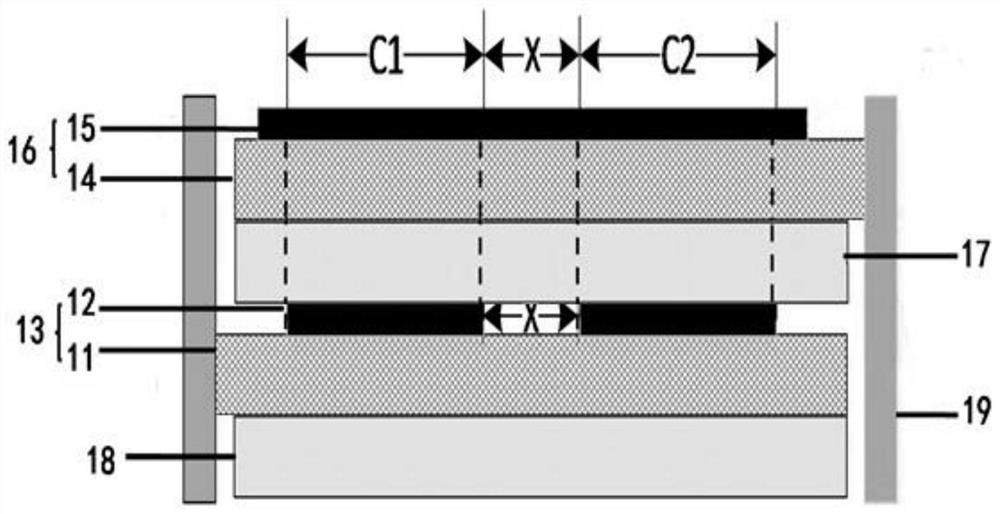

[0033] Such as figure 2 As shown, the film capacitor 01 includes a first electrode layer 13 and a second electrode layer 16, and an insulating layer 17 is filled between the first electrode layer 13 and the second electrode layer 16, ...

Embodiment 2

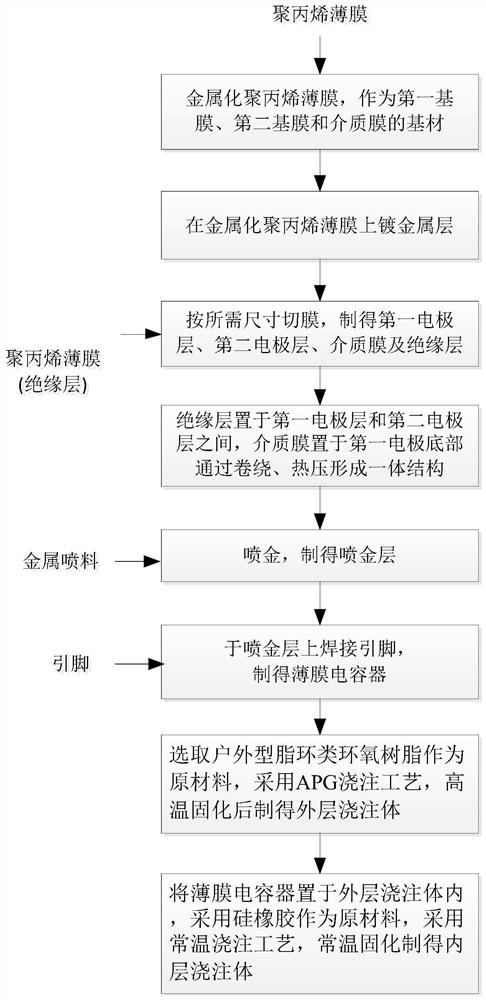

[0041] An embodiment of the present invention provides a method for manufacturing a passive electronic voltage sensor, which can be used to manufacture the passive electronic voltage sensor 01 as described in Embodiment 1, such as image 3 As shown, the method includes the following steps:

[0042] Step 1: select the metallized polypropylene film as the base material, cut out the first base film 11, the second base film 14 and the dielectric film 18 according to the required size, and plate the first metal layer 12 on the first base film 11 to form The first electrode layer 13 is plated with the second metal layer 15 on the second base film 14 to form the second electrode layer 16. The structures of the first metal layer 12 and the second metal layer 15 can be referred to figure 2 ;

[0043] Wherein, the metallized polypropylene film can be prepared by metallizing the polypropylene film.

[0044] Step 2: the pre-cut polypropylene film is placed between the first electrode l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com