Double-motor synchronous motion control device with adjustable wheel track of conveying belt

A technology of synchronous motion and control devices, applied in non-electric variable control, electromechanical devices, two-dimensional position/channel control, etc., can solve problems such as strong limitations, frequent generator accidents, high cost and manpower and material resources, and achieve The effect of high space utilization, light weight and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

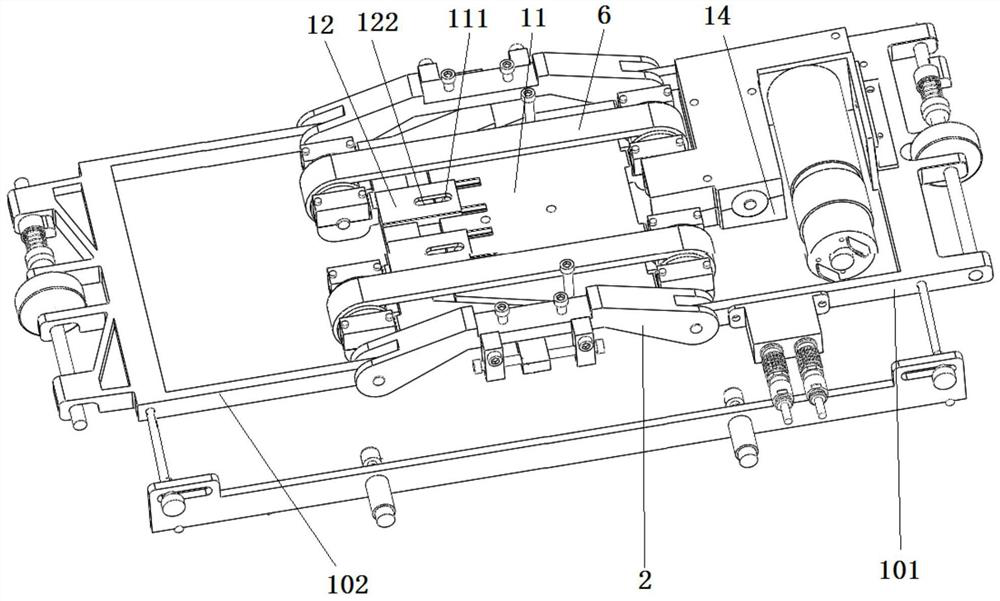

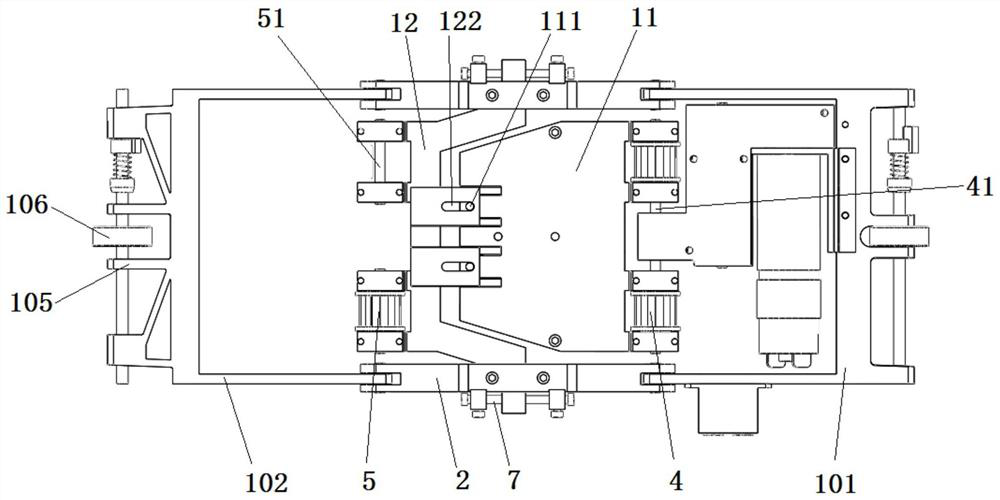

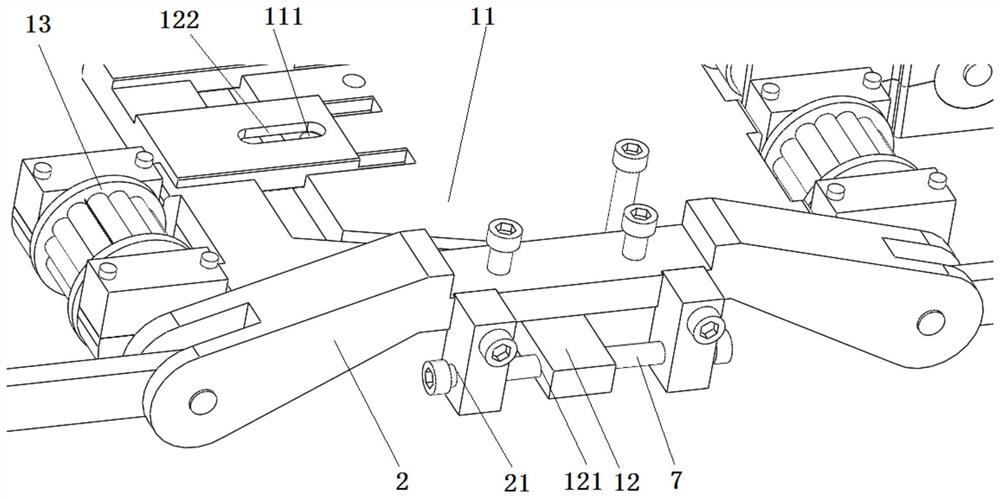

[0023] A dual-motor synchronous motion control device with adjustable wheelbase of the conveyor belt, as shown in the figure, includes a power bracket 1 installed on the outer wall of the stator, and also includes a first mounting plate 11 and a second mounting plate 12, the first mounting plate 11 Fixed on the power bracket 1, the second mounting plate 12 is movably installed on the power bracket 1, the motor 3 and the first pulley 4 driven by the motor 3 are fixed on the first mounting plate 11, and the second mounting plate 12 is fixed on the power bracket 1. The second pulley 5 is equipped with a belt 6, and the two ends of the belt 6 are respectively sleeved on the first pulley 4 and the second pulley 5 and are driven by the first pulley 4. The first pulley 4 and the second pulley 5 are both There are two, and there are two belts 6. Each belt 6 is equipped with a first pulley 4 and a second pulley 5 respectively. The belts 6 are placed in parallel on the left and right. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com