Burner for a gas turbine and method for operating the burner

一种燃烧器、燃烧室的技术,应用在燃烧方法、涡轮/推进装置的燃料控制、涡轮/推进燃料输送系统等方向,能够解决影响等问题,达到减少压力波动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

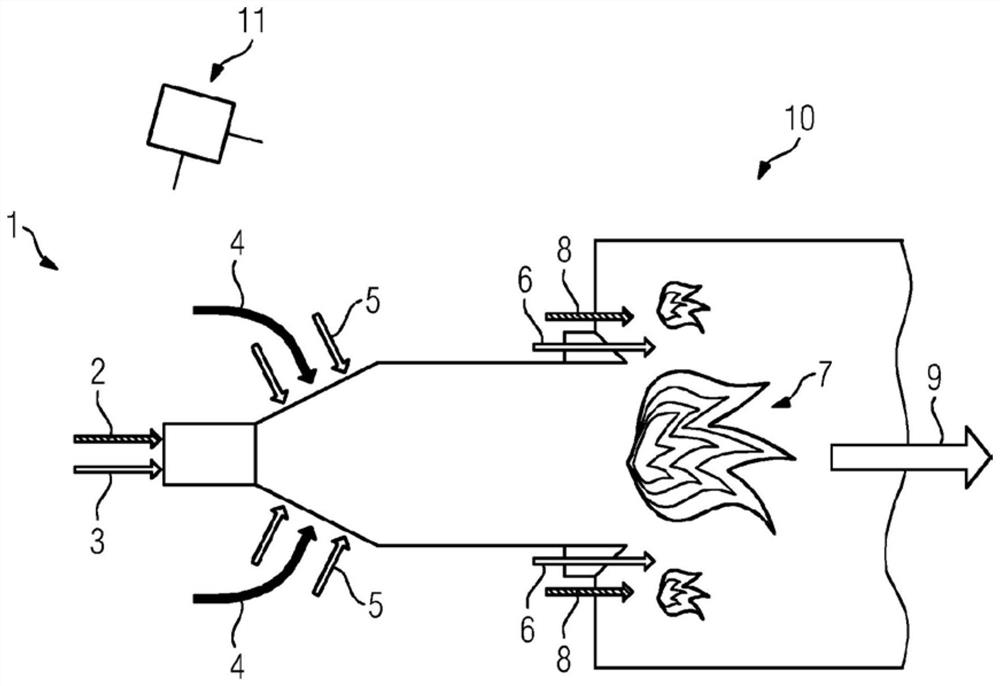

[0035] figure 1 A burner 1 with a combustion chamber 10 , a control unit 11 and fuel stages 2 , 3 , 5 , 6 , 8 is shown. Fuel stages 2 , 3 , 5 , 6 , 8 supply fuel to the combustion chamber 10 . The fuel stages 2 , 3 , 5 , 6 , 8 are a first liquid fuel stage 2 , a first gaseous fuel stage 3 , a second gaseous fuel stage 5 , a third gaseous fuel stage 6 and a second liquid fuel stage 8 . Liquid fuel is supplied to the combustion chamber 10 via liquid fuel stages 2 , 8 and gaseous fuel is supplied to the combustion chamber 10 via gaseous fuel stages 2 , 5 , 6 . Compressed air 4 is also supplied to the combustion chamber 10 . The compressed air 4 is combusted together with fuel in the combustion chamber 10 . exist figure 1 The flame 7 drawn in represents combustion, and the arrow 9 represents the direction of the main flow in the combustion chamber 10 . The control unit 11 is adapted to control the supply of fuel to the combustion chamber 10 via at least one of the fuel stages...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com