Method for preparing tiagabine and precursor compound of tiagabine

The technology of a compound and tiagabine, which is applied in the field of pharmaceutical preparation, can solve the problems of low N-alkylation yield, difficulty in large-scale production and application, waste of piperidine formate, etc., and achieves simplified purification process and easy product purification. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

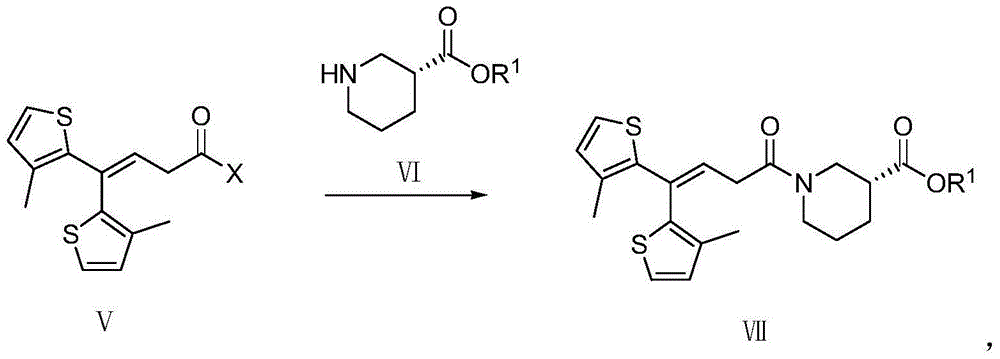

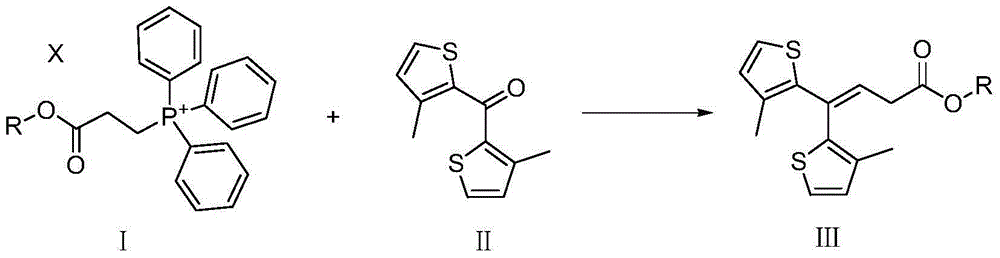

[0046] Embodiment 1: the preparation of the compound of chemical formula III (R=C 2 h 5 )

[0047] Under N2 protection, the compound of chemical formula I (wherein R=C 2 h 5 ) (100.86g, 245mmol) was dissolved in 500ml of dry toluene, the compound of chemical formula II (50.0g, 223mmol) was suspended in 1500ml of dry toluene, and the toluene suspension of the compound of chemical formula II was dropped into chemical formula I under stirring solution of the compound in toluene. Heated to reflux and stirred for 23h. The solution was spin-dried under reduced pressure to obtain a yellow oil. Add 1000ml of n-hexane: acetone (9:1) to the oil, stir, filter, and concentrate the filtrate to obtain 70.67g of compound of chemical formula III, HPLC purity>80%. The obtained compound of chemical formula III contains part of unremoved triphenylphosphine oxide, which will be removed in the next step, and the sample used for structure determination is purified by column chromatography (9:...

Embodiment 2

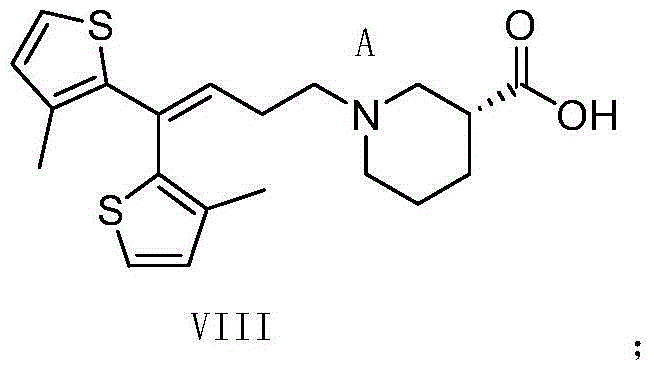

[0048] Embodiment 2: Preparation of the compound of chemical formula IV

[0049] Add 12.0mol / L NaOH (25mL, 300mmol) to the ethanol (300mL) solution of the compound of chemical formula III (40.63g, 151mmol), stir at room temperature for 4h, after TLC monitors that the reaction is complete, filter, the resulting solid is added to 200ml of water, and dilute with concentrated Acidify with hydrochloric acid to pH 4, a white solid precipitates out, stir at room temperature for 2 hours, and then filter with suction. The filter cake was washed with water and dried in vacuum to obtain 30.78 g of the compound of chemical formula IV, with a yield of 90% and a purity of 96% by HPLC. MS(ESI-):277.2; 1 H NMR (500MHz, Chloroform) δ: 2.17(s, 6H), 3.49(d, J=7.0Hz, 2H), 6.53(s, 1H), 7.19–7.03(m, 2H), 7.64–7.49(m ,2H).

Embodiment 3

[0050] Embodiment 3: Preparation of the compound of chemical formula V:

[0051] Put the compound of chemical formula IV (47.33g, 170mmol) into the reaction flask, add 3000ml freshly distilled toluene, stir to dissolve. After cooling in an ice bath, 20ml of N,N-dimethylformamide was added dropwise. Keeping the temperature of the reaction system, 560ml of thionyl chloride was slowly added dropwise at 20°C. After the dropwise addition was completed, the reaction was stirred at room temperature for 1h, and then the reaction was incubated and stirred at 50°C. TLC followed the reaction process (condition: petroleum ether: ethyl acetate = 3:1), the reaction was complete after about 3 hours. Concentrate under reduced pressure to remove the solvent, add 500ml of freshly distilled toluene and continue to concentrate until no solvent is concentrated, and add 500ml of THF to dissolve the residue for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com