Preparation method of antibacterial agent, antibacterial agent thereof, and antibacterial artificial stone using antibacterial agent

An antibacterial agent and artificial stone technology, applied in the field of artificial stone, can solve the problems of easy failure, high price, few sources, etc., and achieve the effects of good safety and environmental protection, strong antibacterial effect and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of an antibacterial agent, comprising the following steps:

[0025] A. After mixing the glass raw materials, a glass mixture is formed;

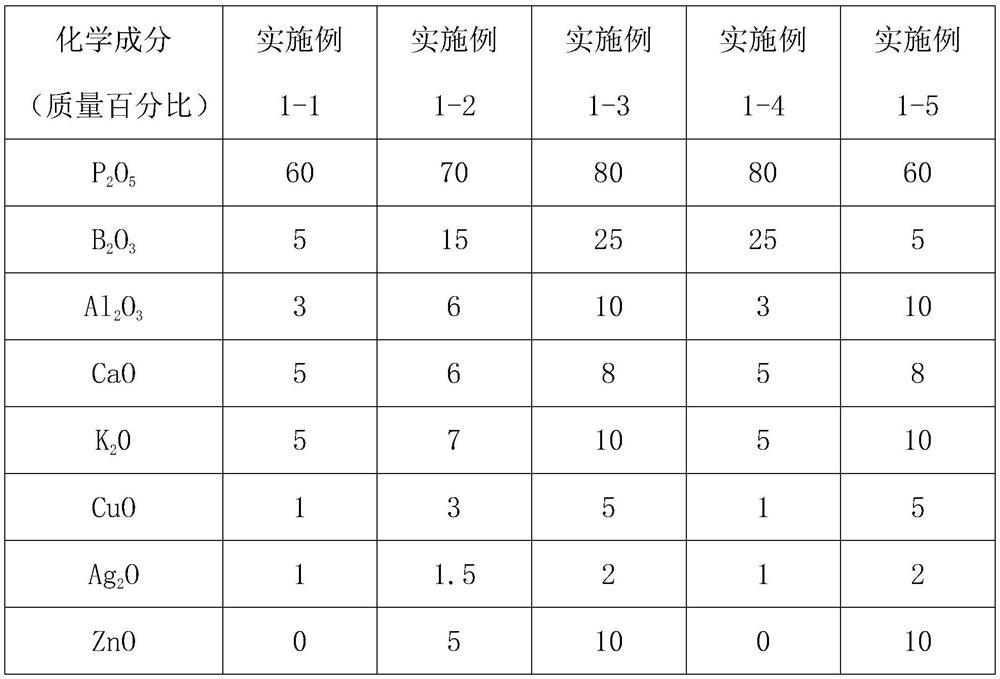

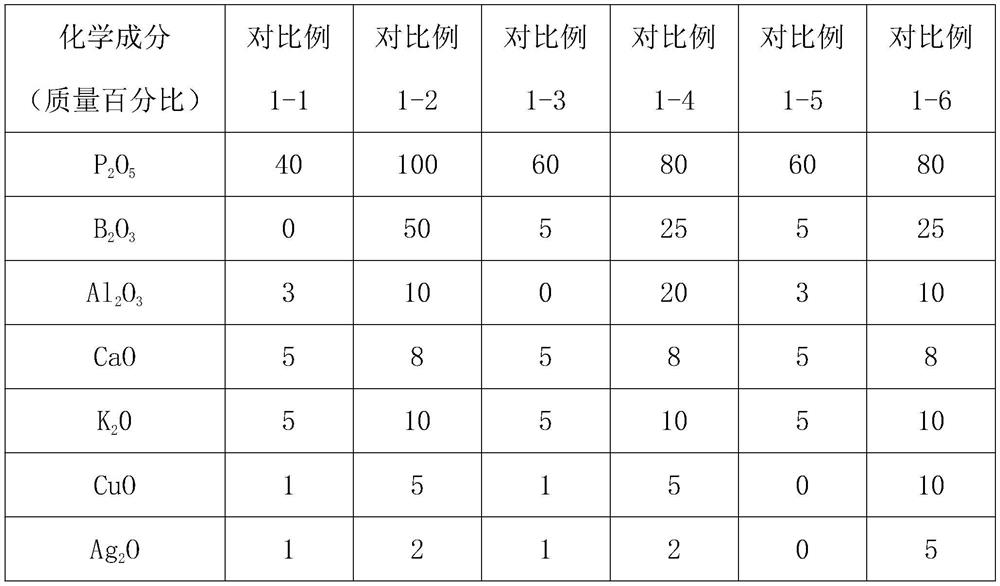

[0026] B. Melting the glass mixture to produce boroaluminophosphate glass that can dissolve antibacterial metal ions; wherein, according to the mass percentage, the chemical composition of the boroaluminophosphate glass includes P 2 o 5 60-80%, B 2 o 3 5~25%, Al 2 o 3 3~10%, CaO5~8%, K 2 05~10%, CuO1~5%, Ag 2 O1~2% and ZnO0~10%;

[0027] C. Add boroaluminophosphate glass into a ball mill for ball milling to form an antibacterial agent.

[0028] In the past, antibacterial and antibacterial agents containing silver ions were commonly used in stone materials. Since metallic silver is a precious and rare metal, it is expensive and costly. Therefore, it has become the biggest obstacle to the popularization of stone materials with antibacterial and antibacterial functions. In addition, silver ions will darken ...

Embodiment 2-1

[0096] Example 2-1: The mixing ratio of antibacterial agent, artificial stone filler and inorganic binder is 7:79:14;

Embodiment 2-2

[0097] Example 2-2: The mixing ratio of antibacterial agent, artificial stone filler and inorganic binder is 10:79:14;

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com