Rapid cooling device for processing fried foods

A fried food and rapid cooling technology, which is applied in the field of food processing, can solve the problems of accumulation, low cooking oil, and messy equipment, etc., and achieve the effects of increasing the diffusion speed, reducing oil, and accelerating cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

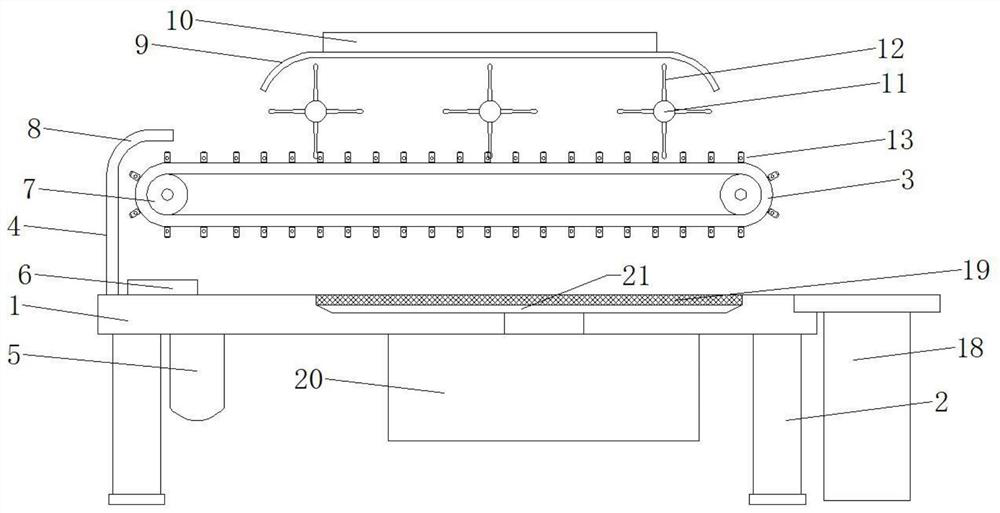

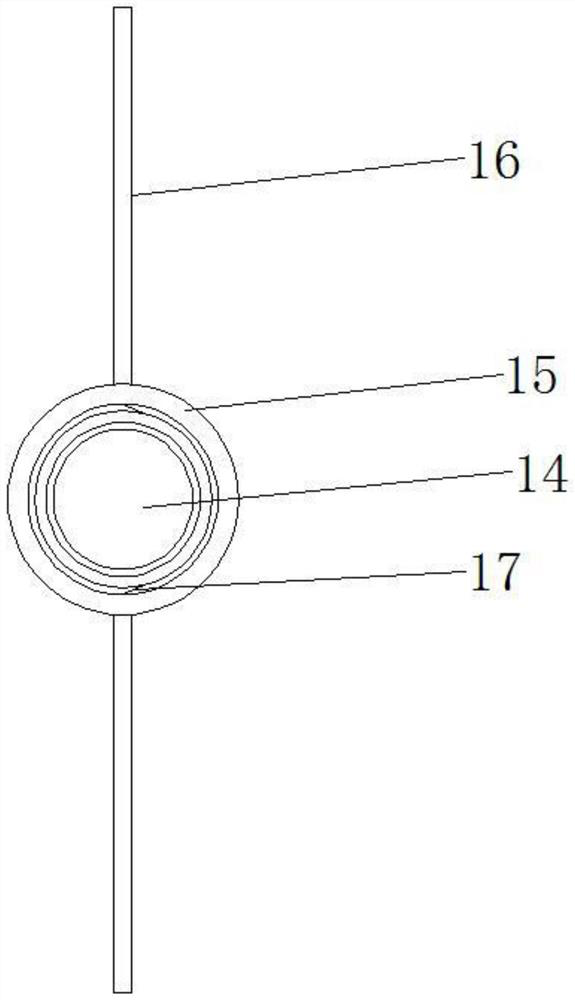

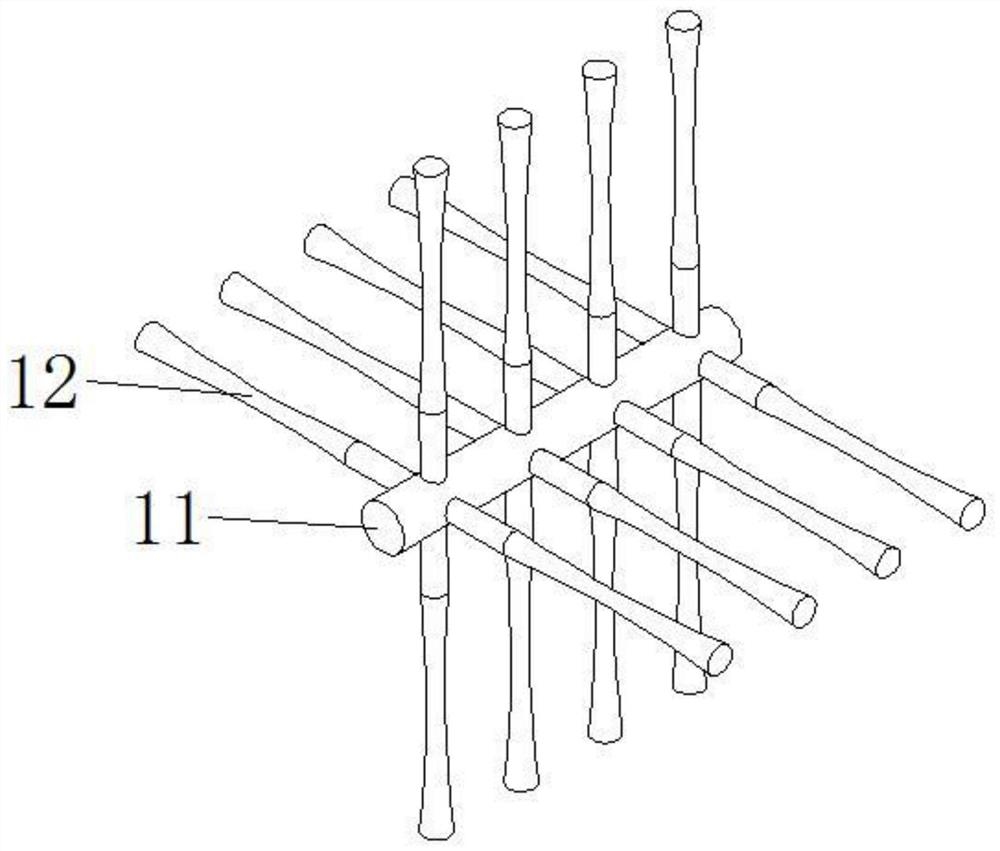

[0021] Please refer to the figure, in the embodiment of the present invention, a fast cooling device for fried food processing includes a base 1, legs 2, a conveyor belt 3, a baffle plate 4 and a refrigeration compressor 5; the four corners of the bottom of the base 1 Outriggers 2 are fixedly installed on the top, and the base 1 is supported. A refrigeration compressor 5 is fixedly installed on the lower side of the base 1. The refrigeration compressor 5 generates cooling to cool the fried food in the device; the conveyor belt 3 is horizontally arranged above the base 1, and both ends are wound with a horizontal transmission wheel 7, and the transmission wheel 7 is coaxially fixedly connected to the motor, and the transmission wheel 7 is driven by the motor to rotate, so that the conveyor belt 3 moves and will fall on the conveyor belt 3 The food on the conveyor belt 3 is transported to the right; on the base 1 corresponding to the left end of the conveyor belt 3, a vertical ba...

Embodiment 2

[0027] On the basis of Embodiment 1, the conveyor belt 3 is a hollow structure. Specifically, the conveyor belt 3 includes a belt body 31, and the hollow inside the belt body 31 is a collection chamber 32, and the corresponding belt body above the collection chamber 32 The upper surface of 31 is provided with several through holes 33, and the fried food falling on the conveyer belt 3 is located above the collection chamber 32, and the oil in it enters into the collection chamber 32 through the through holes 33, and is stored in the collection chamber 32. Moving along with the conveyor belt 3, in order to prevent fried food from entering the collection chamber 32, a blocking material net 34 is embedded in the upper end of the through hole 33, so that the oil can only fall from the through hole 33 into the collection chamber 32.

[0028]The upper surface of the base 1 corresponding to the bottom of the conveyor belt 3 is provided with a collection port 21, the right end of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com