Dandelion-like floccule adsorption equipment for printing and dyeing waste gas

An adsorption equipment, dandelion technology, applied in dispersed particle separation, chemical instruments and methods, dispersed particle filtration, etc., can solve problems such as position reversal, and achieve the effect of improving interception density, improving treatment effect and efficiency, and increasing density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

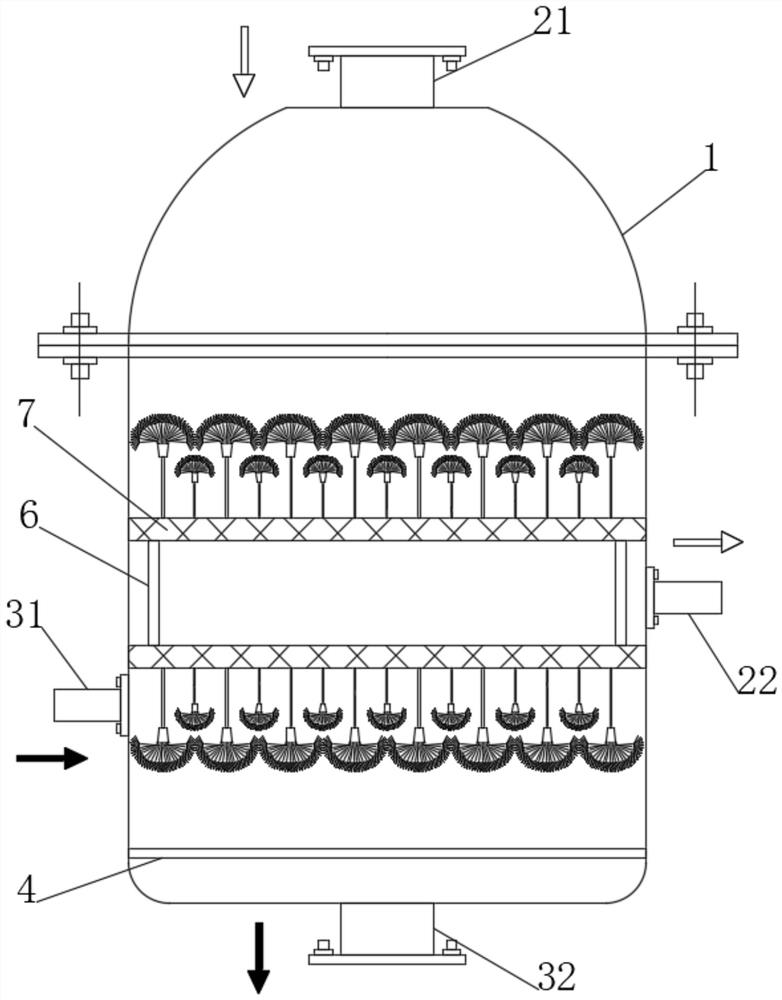

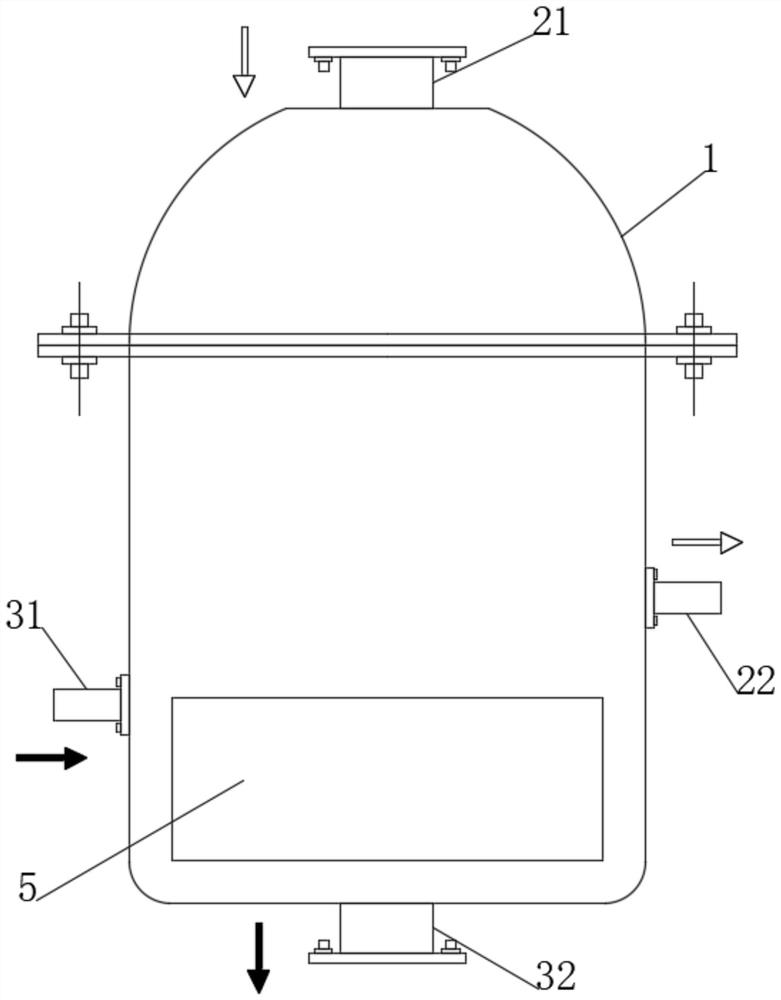

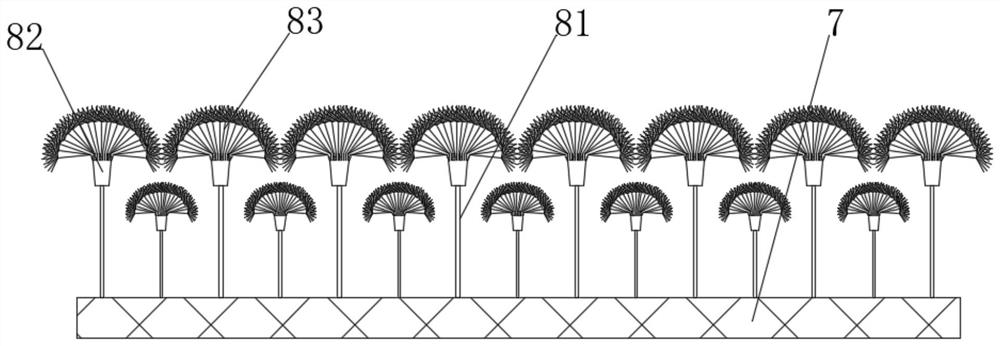

[0043] see Figure 1-2 , the hollow arrow in the figure indicates the flow direction of the exhaust gas, and the solid arrow indicates the flow direction of the gas that needs to be cleaned. A floc adsorption equipment imitating dandelion-style printing and dyeing exhaust gas includes the equipment body 1, the upper and lower ends of the equipment body 1 The air inlet pipe 21 and the air outlet pipe 32 are respectively fixedly connected, the left and right ends of the device body 1 are respectively fixedly connected with the air inlet pipe 31 and the air outlet pipe 22, the air inlet pipe 21, the air outlet pipe 22, the air inlet pipe 31 and the air outlet pipe 32 respectively Connected with the equipment body 1, the outer end of the equipment body 1 is equipped with a sealed door 5, the sealed door 5 is located below the ventilation inlet pipe 31, the inside of the equipment body 1 is connected with a two-way filter screen through an electric rotating shaft, and the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com