Urban pollution treatment device

A pollution control and urban technology, applied in the field of urban pollution control, can solve the problems of separation of difficult-to-waste metals and ordinary waste slag, pollute the environment, occupy a large space, etc., and achieve the effect of easy separation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

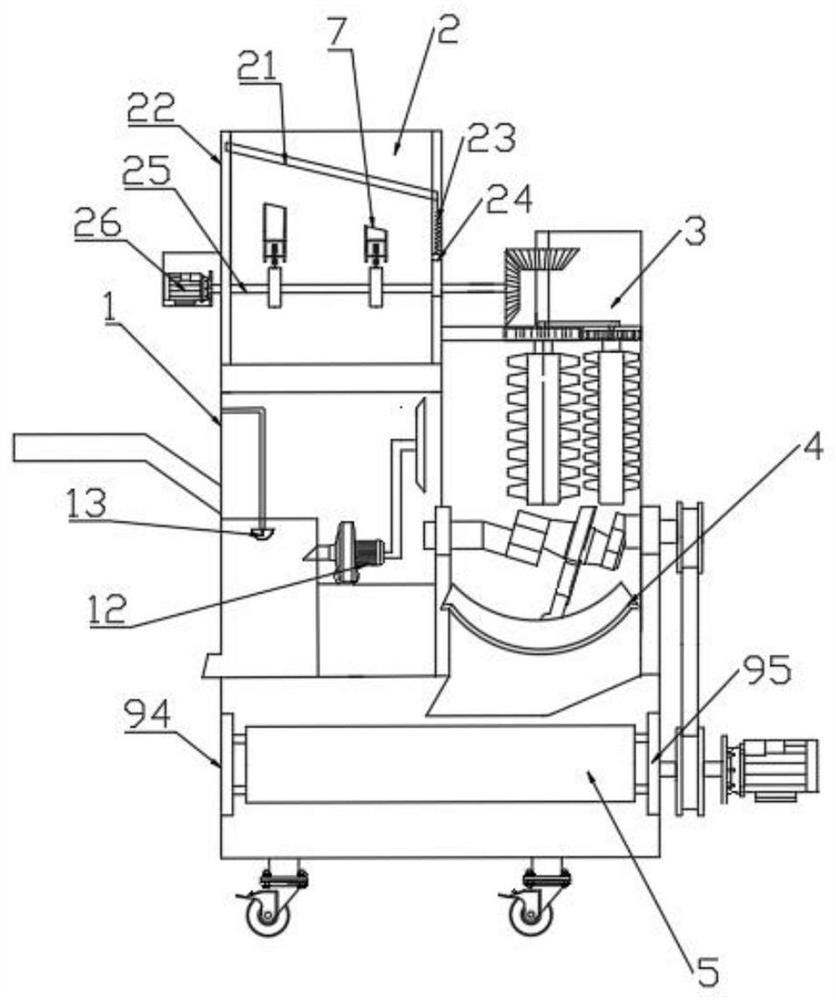

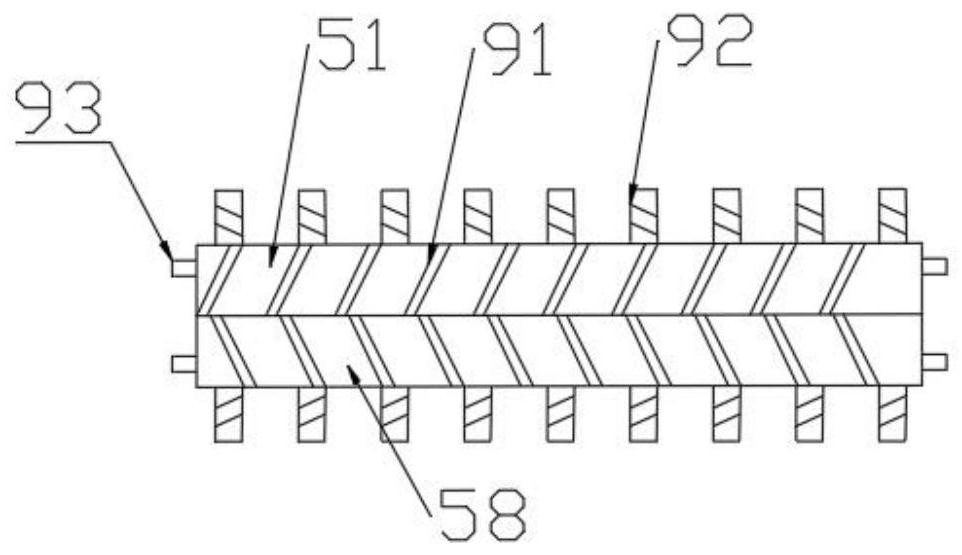

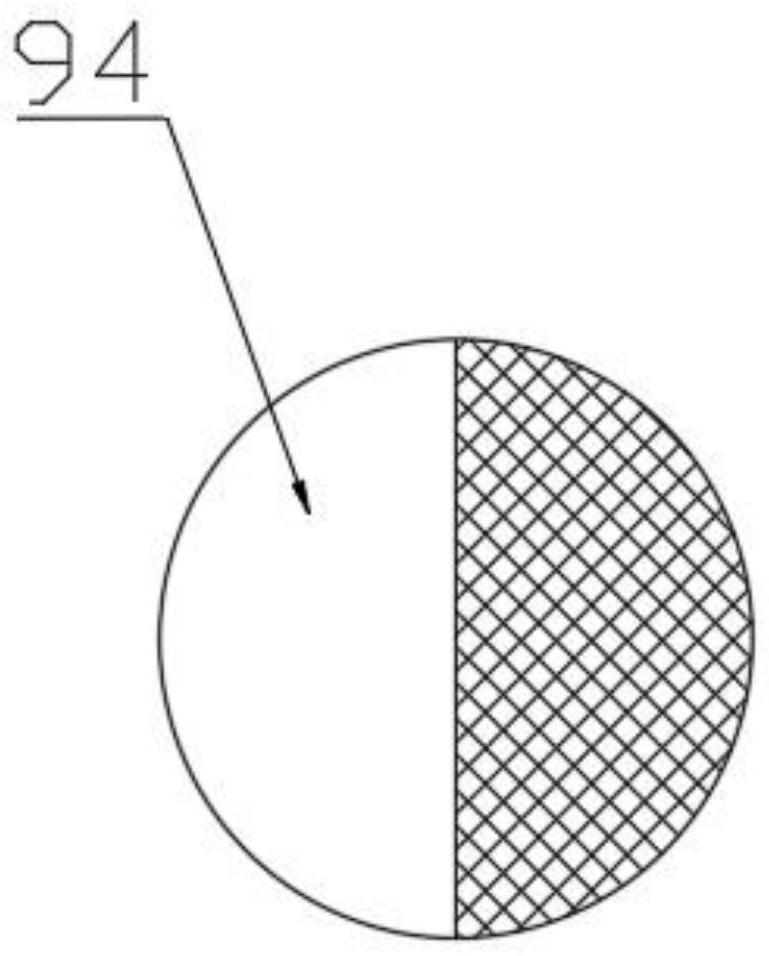

[0031] refer to Figure 1-7 , an urban pollution control device, comprising a fuselage 1, a crushed soil screening device 2 is arranged inside the fuselage 1, a handle is connected to the side of the fuselage 1, and a crushing device 2 is connected to the end of the crushed soil screening device 2 away from the handle. Device 3, the grinding device 4 is arranged below the crushing device 3, and the separation device 5 is provided below the grinding device 4. The separation device 5 includes a first half shaft 51, and the first half shaft 51 is connected with a second half shaft 58. The auxiliary element 9 is connected to the outside of the half shaft 51, and the auxiliary element 9 includes a conductive block 93, the conductive block 93 is connected to the two sides of the first half shaft 51, and a coil 91 is wound on the outer circumference of the first half shaft 51. The outside of the half shaft 51 is connected with several identical electromagnets 92, the end of the separ...

Embodiment 2

[0039] refer to Figure 8 , a kind of urban pollution control device, the present embodiment is compared with embodiment 1, and the grinding device 4 comprises support rod 41, and the quantity of support rod 41 is two, and the outside of support rod 41 is connected with rotating shaft 42, two support A rotating block 43 is connected between the rods 41 , the rotating block 43 is connected with a second turntable 44 , a grinding ball 45 is connected below the second turntable 44 , and a grinding dish 46 is connected below the grinding ball 45 .

[0040] Working principle: when in use, the rotating block 43 is driven to rotate by the rotating motor, and the second rotating disc 44 is driven to rotate at the same time, and the grinding ball 45 is driven to move inside the grinding dish 46 to grind the crushed construction waste into fine particles in time. It is convenient for the next step of separation work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com