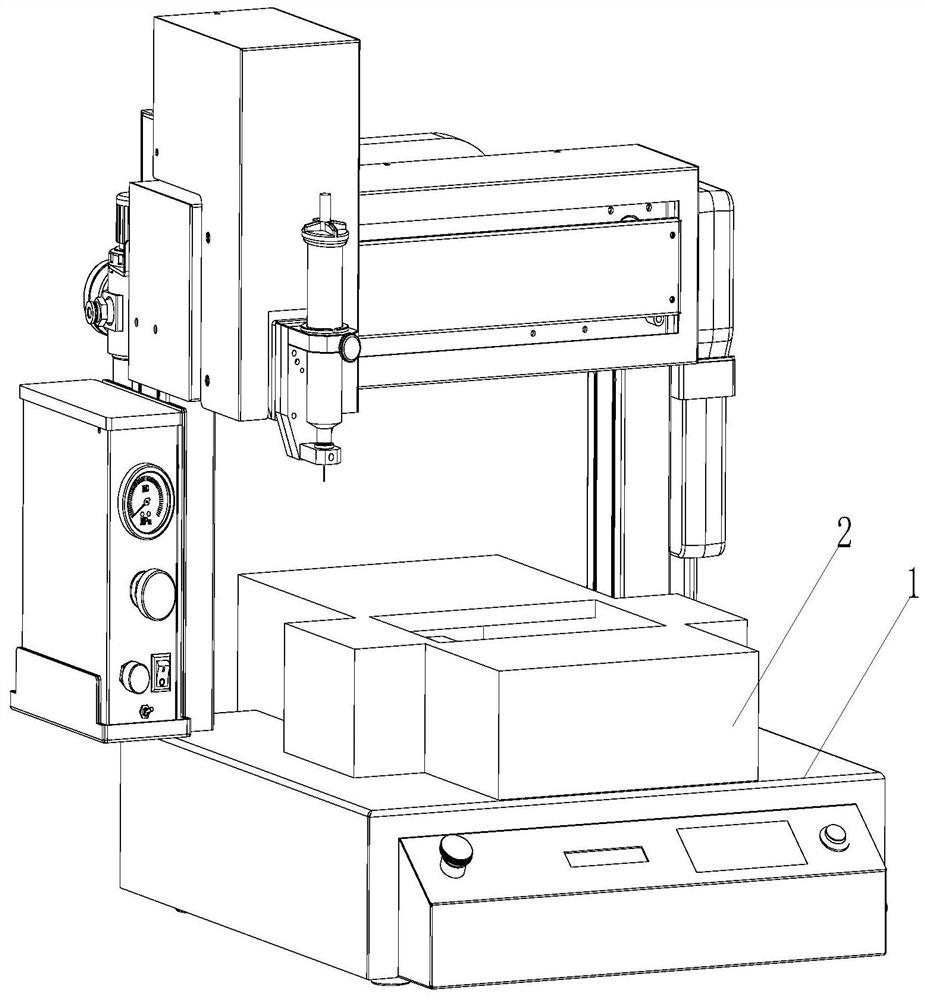

Multi-directional dispenser for socks processing and using method thereof

A multi-directional, glue-dispensing technology, applied in the device for coating liquid on the surface, pre-treatment surface, spray device, etc., can solve the problems of low production efficiency, residual glue, and inability to get fast and efficient cleaning, etc. To achieve efficient and fast removal, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

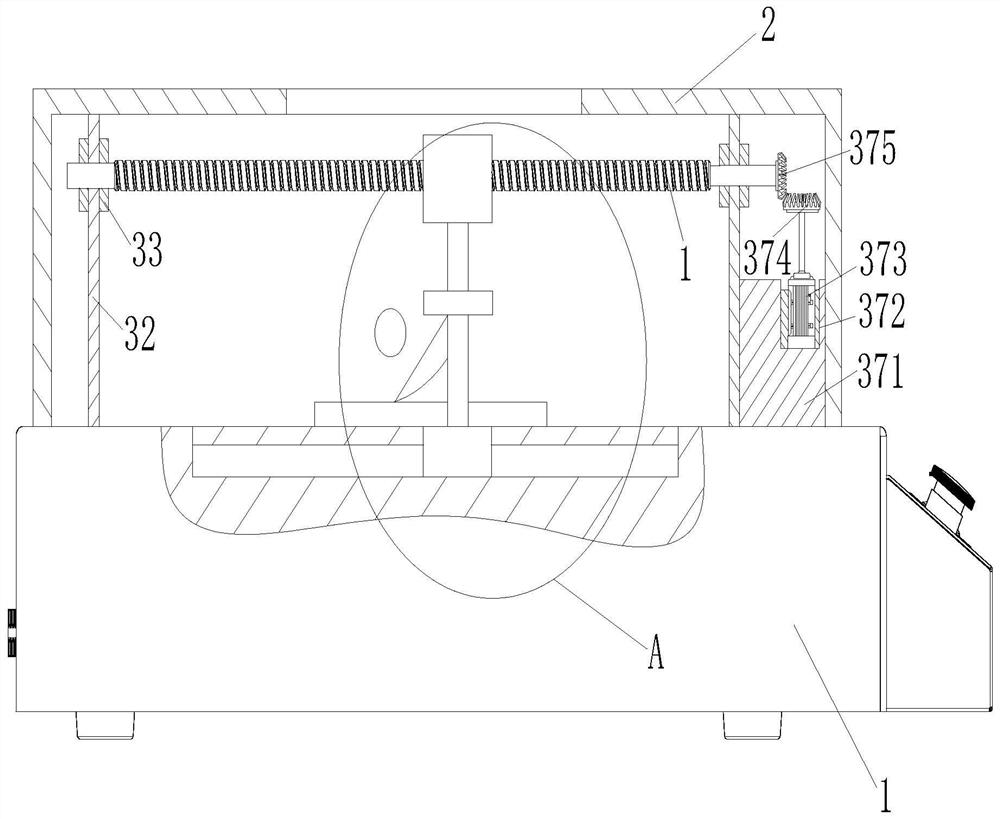

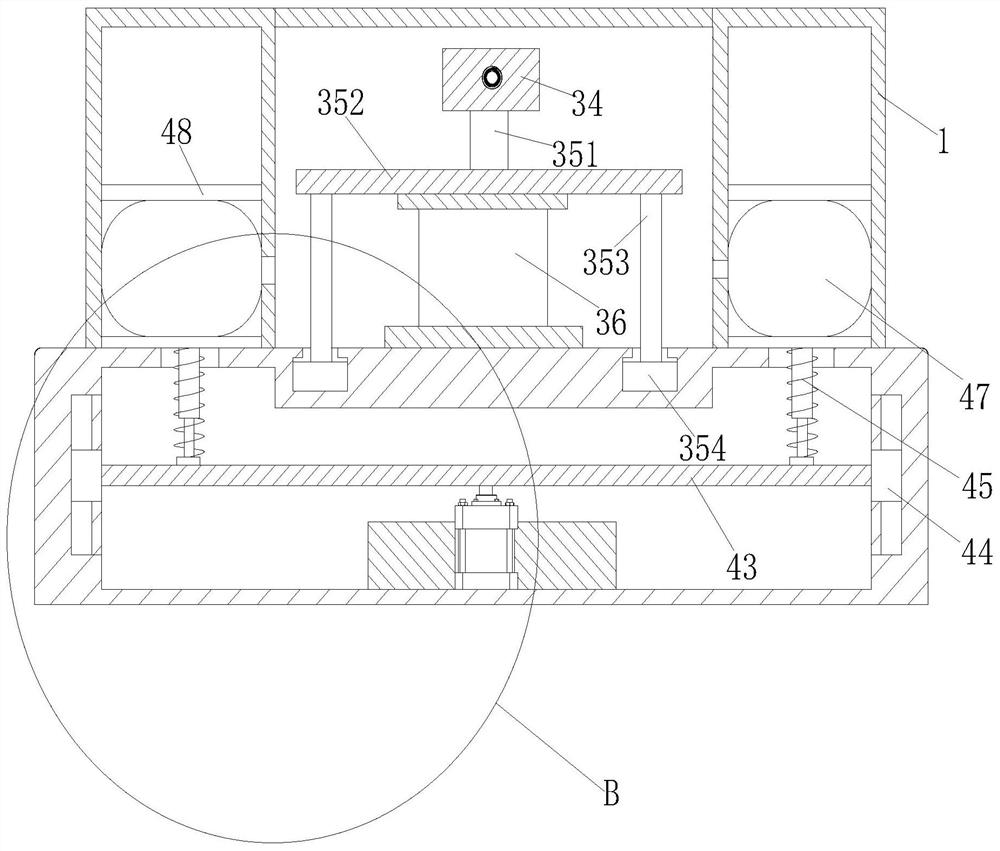

[0031] As an embodiment of the present invention, the air-drying mechanism 4 includes a first fixed block 41, a cylinder 42, a push plate 43, a first slider 44, a spring rod 45, a squeeze plate 46, an air bag 47 and a baffle 48; The cylinder 42 is fixedly connected to the bottom of the inner cavity of the base 1 through the first fixing block 41; the side wall of the inner cavity of the base 1 is provided with a first chute 11; the push plate 43 is slidably connected in the chute through a slider The spring rod 45 is fixed on the top of the push plate 43; the extrusion plate 46 is arranged on the top of the base 1; the baffle plate 48 is fixed on the side wall of the housing 2; the air bag 47 is arranged on Between the baffle plate 48 and the extrusion plate 46; during work, when applying glue to the product, the glue needs to be air-dried. At this time, the cylinder 42 push rod push plate 43 moves, and there is a second groove on the side wall of the inner cavity of the base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com