A new joint bolt forming device

A molding device, a new type of technology, applied in the direction of feeding device, positioning device, quenching device, etc., to achieve the effect of reducing heat flow rate, avoiding work, and reducing a large amount of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

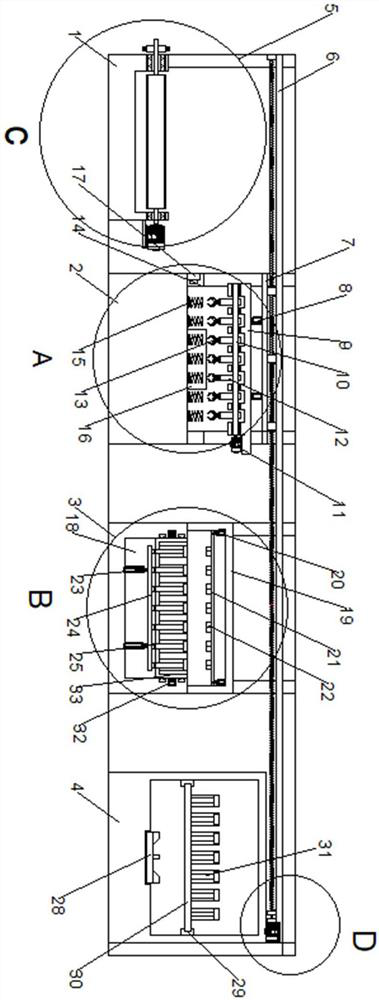

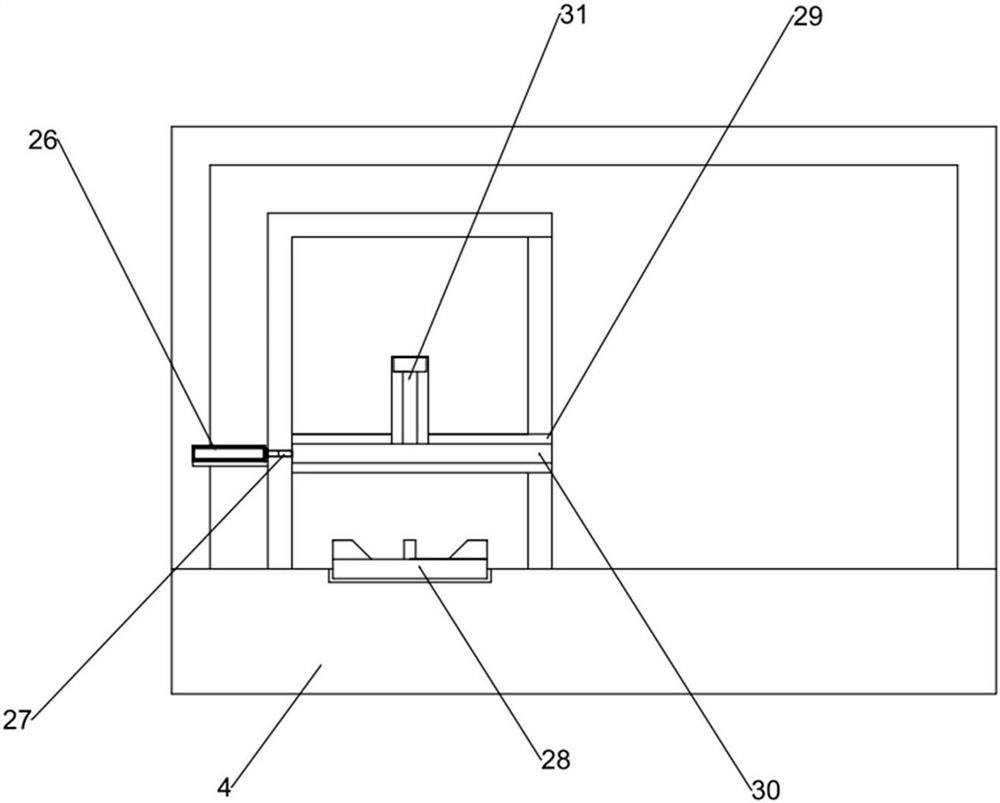

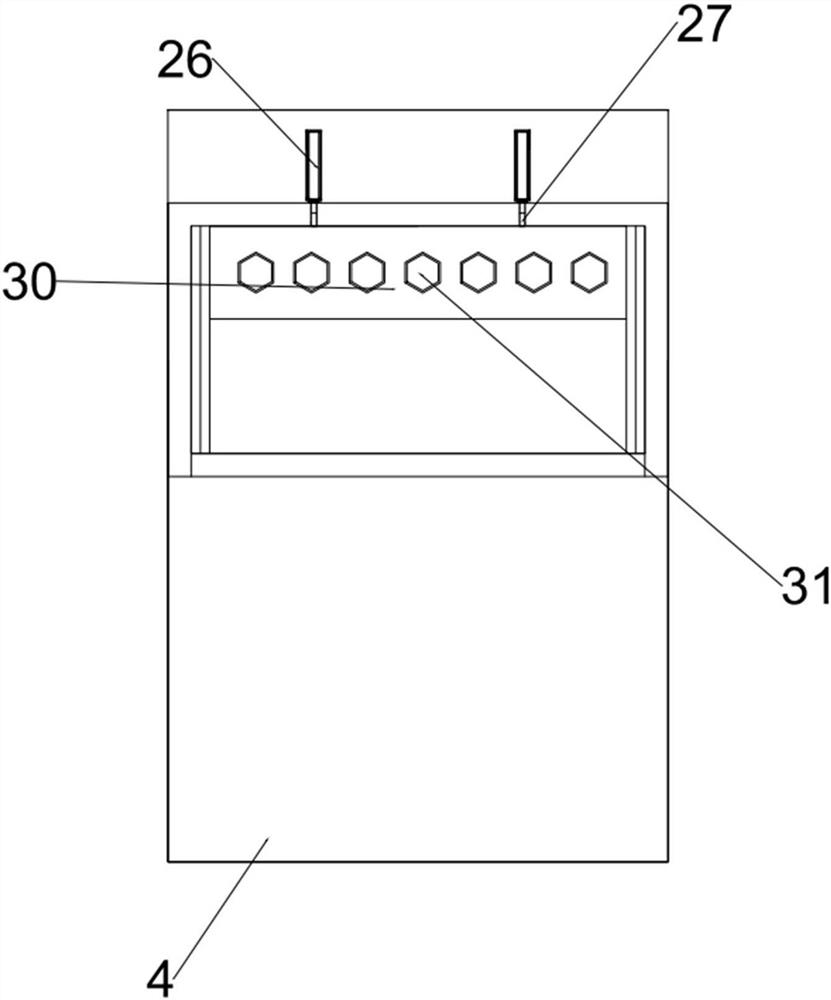

[0035] Embodiment: through the operation of a pair of horizontal lead screw modules 6, the horizontal moving plate 7 on the moving end of the pair of horizontal lead screw modules 6 is driven to move horizontally, and the two pairs of telescopic multi-stage hydraulic pushers on it are driven by the horizontal moving plate 7. Rod 8, toothed box 9, several transport rods 12 and several transport claws 13 are brought above the transport platform 1, stretched by two pairs of telescopic multi-section hydraulic push rods 8, and driven by the transport drive 11 to drive the drive on the drive end. The shaft 10 drives several conveying rods 12 to rotate through the drive shaft 10, so that several conveying rods 12 form a 90-degree angle with several steel raw materials, and the raw materials are picked up by several conveying claws 13 on several conveying rods 12. Two pairs of telescopic multi-segment hydraulic push rods 8 are contracted, and the two pairs of telescopic multi-segment h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com