Steel pipe and welding system thereof

A technology for welding systems and steel pipes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems affecting welding quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

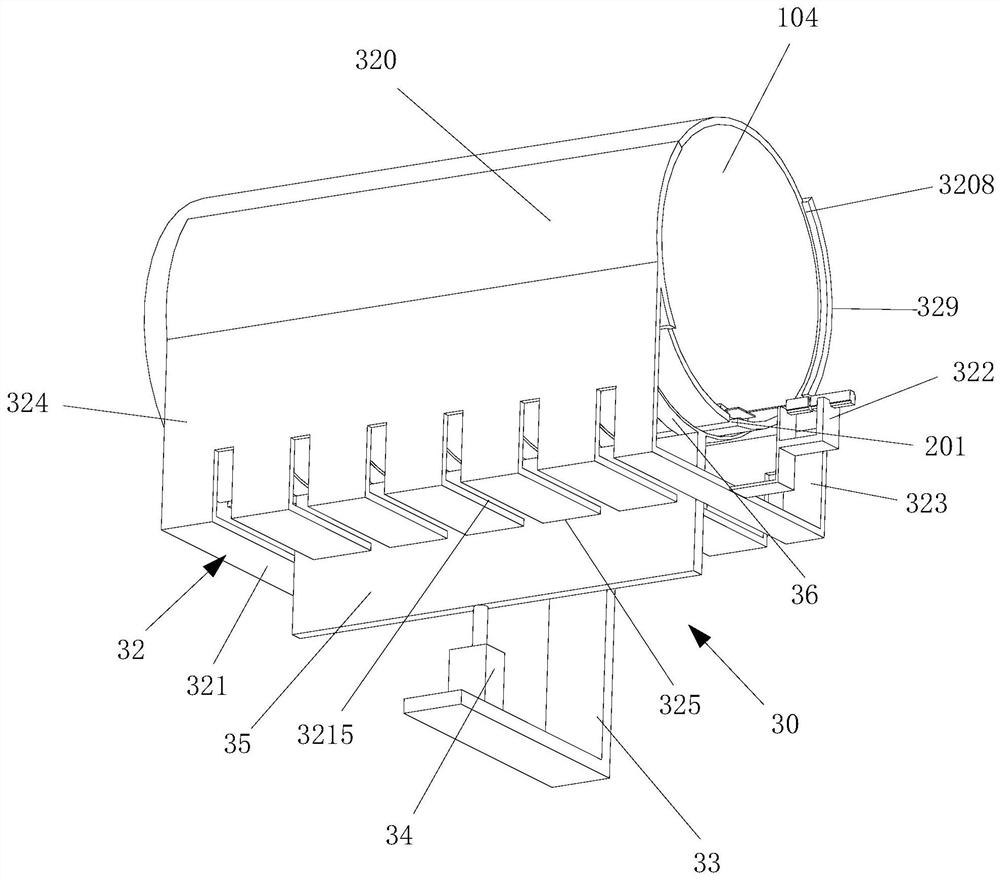

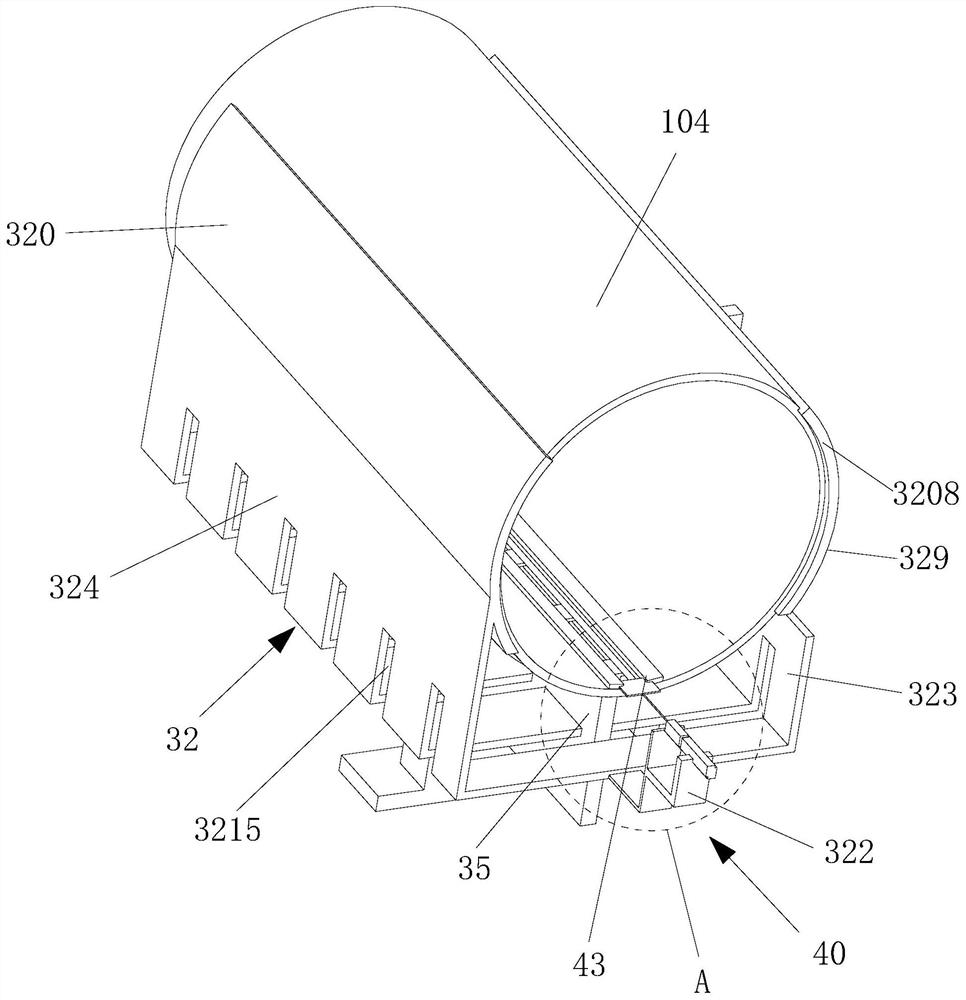

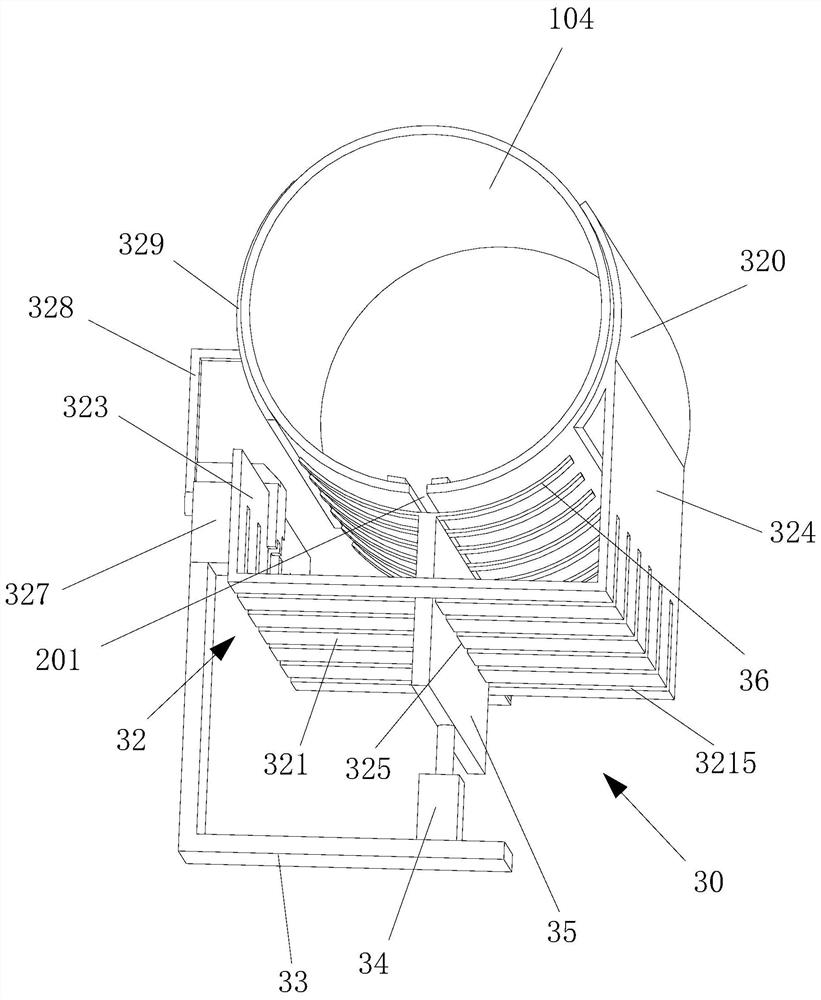

[0019] The invention relates to a steel pipe and its welding system. For example, steel pipes are welded pipes welded by this welding system. The steel pipe is a thin-walled steel pipe. For example, a steel pipe welding system includes a jacking assembly and a welding mechanism. The jacking assembly includes a jacking frame, an L-shaped frame, a jacking cylinder, a jacking plate, and a plurality of arc-shaped jacking bars. For example, the lifting frame includes a mounting plate, a first side wall plate and a second side wall plate. For example, the middle part of the mounting plate is provided with a transverse groove, the first side wall plate and the second side wall plate are respectively vertically fixed on opposite sides of the mounting plate, and the top of the L-shaped frame is fixed on the first side wall plate. For example, the bottom of the L-shaped frame is fixed on the ground, and the jacking cylinder is installed on the bottom of the L-shaped frame. It is fixe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap