Electric heating cutting machine for foam round cutting

A cutting machine, circular technology, applied in metal processing and other directions, can solve problems such as damage to material integrity, operator injury, increase production costs, etc., to achieve the effect of reducing energy dissipation, saving energy, and reducing the length of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

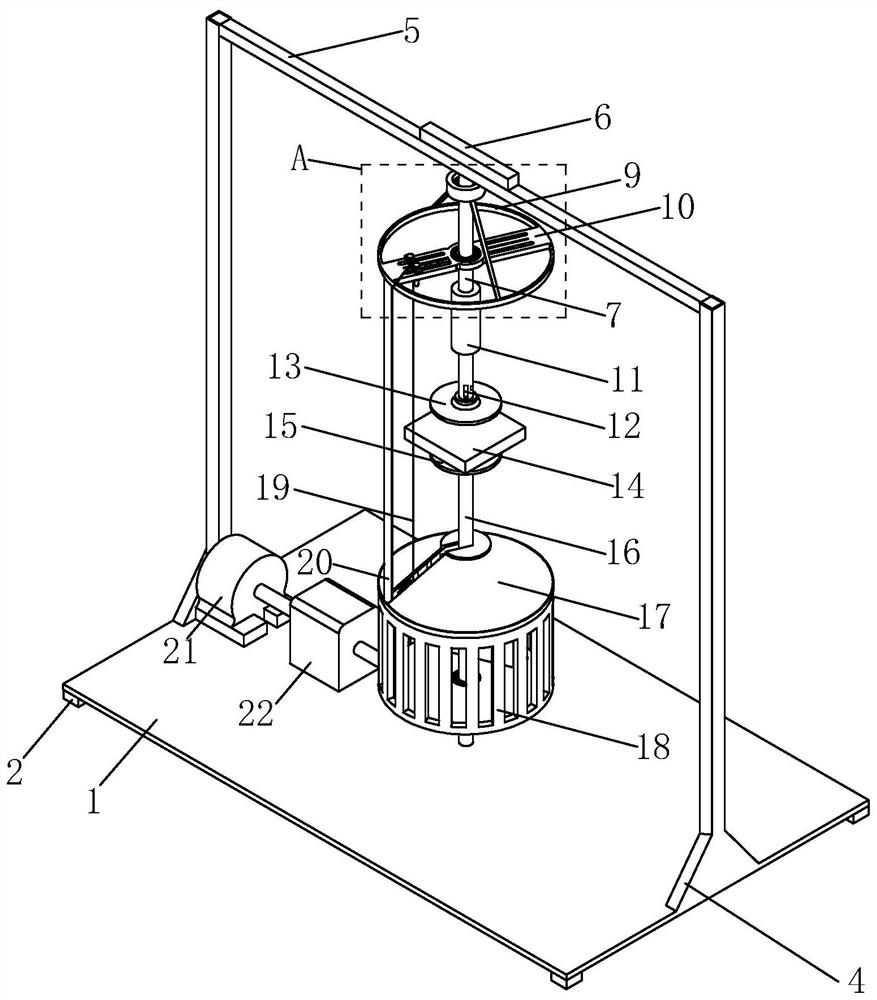

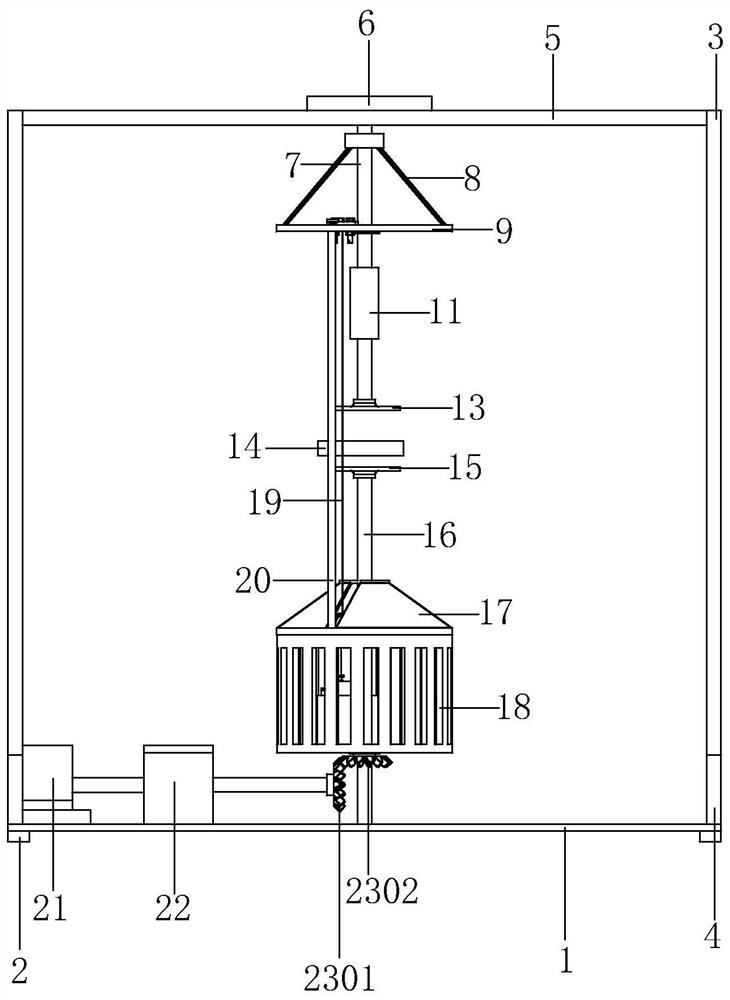

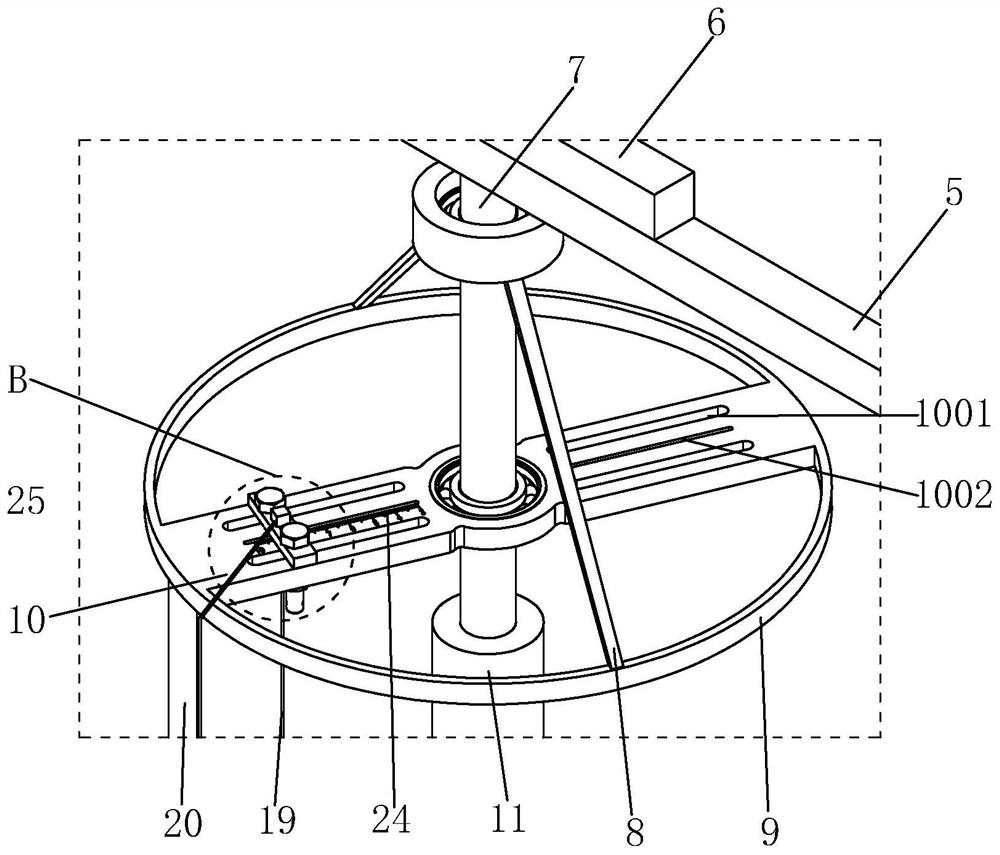

[0024] Specific implementation mode one: as Figure 1 to Figure 7 As shown, the present invention discloses an electric thermal cutting machine for circular foam cutting, including a supporting mechanism, a pressing and positioning mechanism, a measuring and cutting mechanism, and a driving mechanism; the supporting mechanism includes a bottom plate 1, a beam 5, a level measuring instrument 6 and Two vertical rods 3; the pressing and positioning mechanism includes a fixed rod 7, a cylinder 11, a laser light 12, a pressure plate 13, a placement table 15 and a support rod 16; the measuring and cutting mechanism includes a rotating frame 9 and an upper scale 10 , upper cover plate 17, rotating container 18, cutting heating wire 19, fixed connecting rod 20, battery 29, stepless thermostat 31, lower scale 33, two connectors 26 and two pressing pieces 28; the bottom plate 1 The upper surface of the upper surface is fixedly connected with the lower ends of two vertically arranged ver...

specific Embodiment approach 2

[0025] Specific implementation mode two: as figure 1 , 2 As shown, this embodiment is a further description of Embodiment 1. The lower end of the bottom plate 1 is fixed with a plurality of (four) pads 2, and the multiple (four) pads 2 are arranged in a rectangular shape. And be fixed on the corner of the lower surface of the base plate 1 to ensure that the base plate 1 is in a horizontal state.

specific Embodiment approach 3

[0026] Specific implementation mode three: as figure 1 , 2As shown, this embodiment is a further description of specific embodiment 1 or 2. A reinforcing rib 4 is fixed between the lower end of each vertical rod 3 and the bottom plate 1 to improve the stability of the telescopic rod 3 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap