Novel segmented heating roller and calender with same

A segmented heating and calendering technology, which is applied to household appliances, other household appliances, flat products, etc., can solve the problems of uneven temperature between the middle and both ends of the calender roll surface, three high and two low transverse thicknesses, etc., and achieve an improvement in the overall Heating method, ensuring uniformity, and solving the effect of horizontal thickness unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

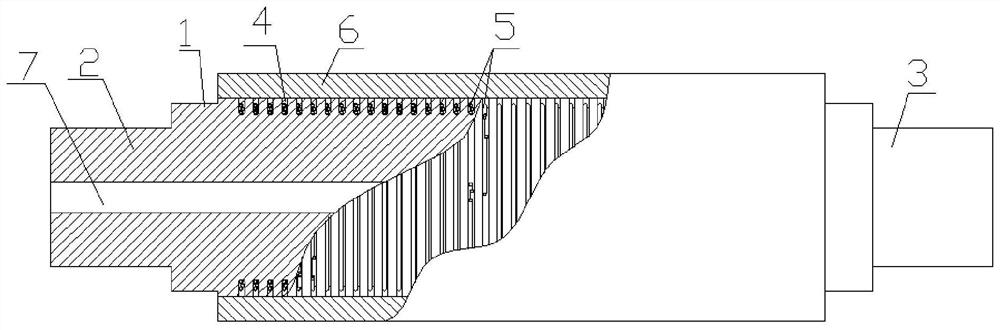

[0034] This embodiment provides a new segmented heating roller, the structure of which is shown in the attached figure 1 As shown: including the roller core 1 and the left shaft end 2 and the right shaft end 3 arranged at both ends of the roller core 1, the outer wall of the roller core 1 is evenly distributed with a plurality of mutually parallel grooves along the axial direction 4. The groove 4 is opened along the circumferential direction of the roller core 1 and has a circular structure, the electromagnetic coil 5 is arranged in the groove 4, and the outer wall of the roller core 1 is covered with a roller cover 6, A threading hole 7 for setting a power line and / or a signal line is provided in the middle of the roller. The number and density of electromagnetic coils are determined according to the actual situation. The higher the density, the smaller the temperature difference between the heating sections, the fewer the number of electromagnetic coils, and the lower the c...

Embodiment 2

[0043] This embodiment provides a new segmented heating roller, the structure of which is as described in Embodiment 1.

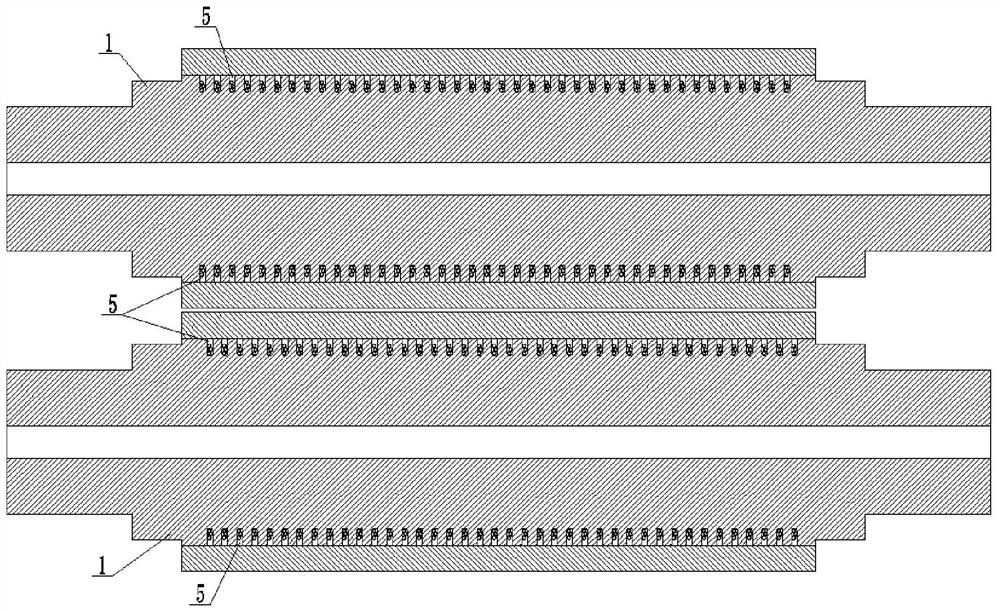

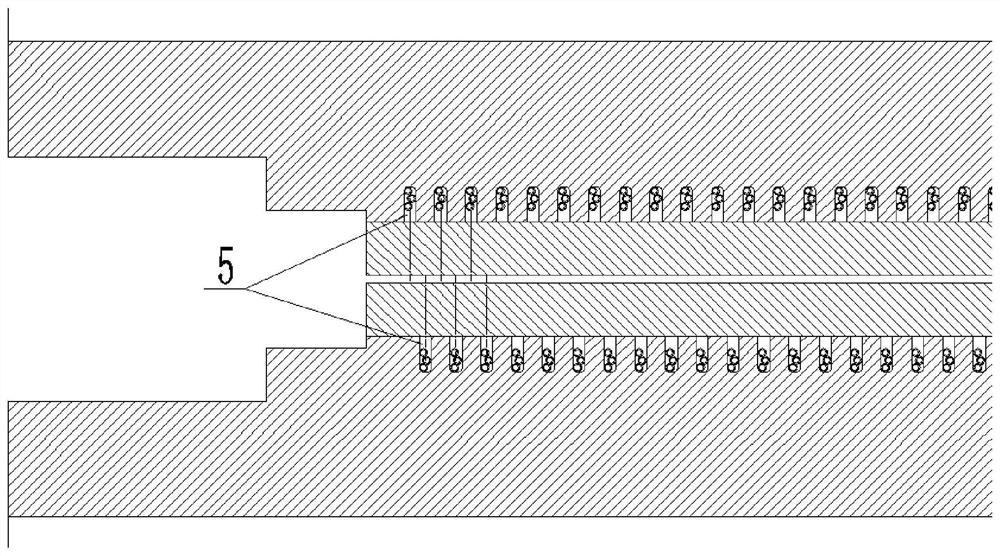

[0044] This embodiment also provides a calender with this structure, the calender has a plurality of rollers described in Embodiment 1, and the electromagnetic coils 5 on adjacent rollers are arranged alternately, as figure 2 and 3 shown. And the electromagnetic coils 5 on adjacent rollers are arranged alternately. That is, staggering the heating sections of the upper and lower adjacent rollers can effectively eliminate the stepwise temperature difference between the heating sections of the electromagnetic coil (for example, in the last roller, the material is between the two electromagnetic heating sections, The temperature is relatively low, and the material flows to the next adjacent roller as the roller rolls. Because the electromagnetic coils on the adjacent rollers are staggered, the material is in the electromagnetic coil of the next adjacent roll...

Embodiment 1 and 2

[0045] Embodiment 1 and 2 have the following beneficial effects:

[0046] (1) The overall heating method of the traditional calender roll is improved, the processing area of the calender roll is divided into several sections, and the longitudinal segmental heating is carried out, and each section is independently heated and controlled, which is different from the conventional heating of the calender roll (calender roll conventional Heating means that there is only one set of heating device for the entire calender roll, and the overall heating of the calender roll cannot solve the problem of uneven temperature between the middle and both ends of the calender roll surface), and the temperature of the middle and both ends of the roll surface is controlled separately to solve the problem Solved the problem of uneven temperature in each area of the roller surface;

[0047] (2) The working power of each electromagnetic coil is controlled separately by the controller, and the rol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap