Method for uniformizing temperature field of current assisted sintered nano-silver soldering paste on basis of DBC (Direct Bonded Copper) ceramic substrate

A uniform current and auxiliary sintering technology, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve problems such as poor reliability of fatigue resistance, low mechanical strength, and uneven temperature distribution, so as to achieve uniform distribution, prolong service life, Effect of improving mechanical strength and fatigue resistance reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

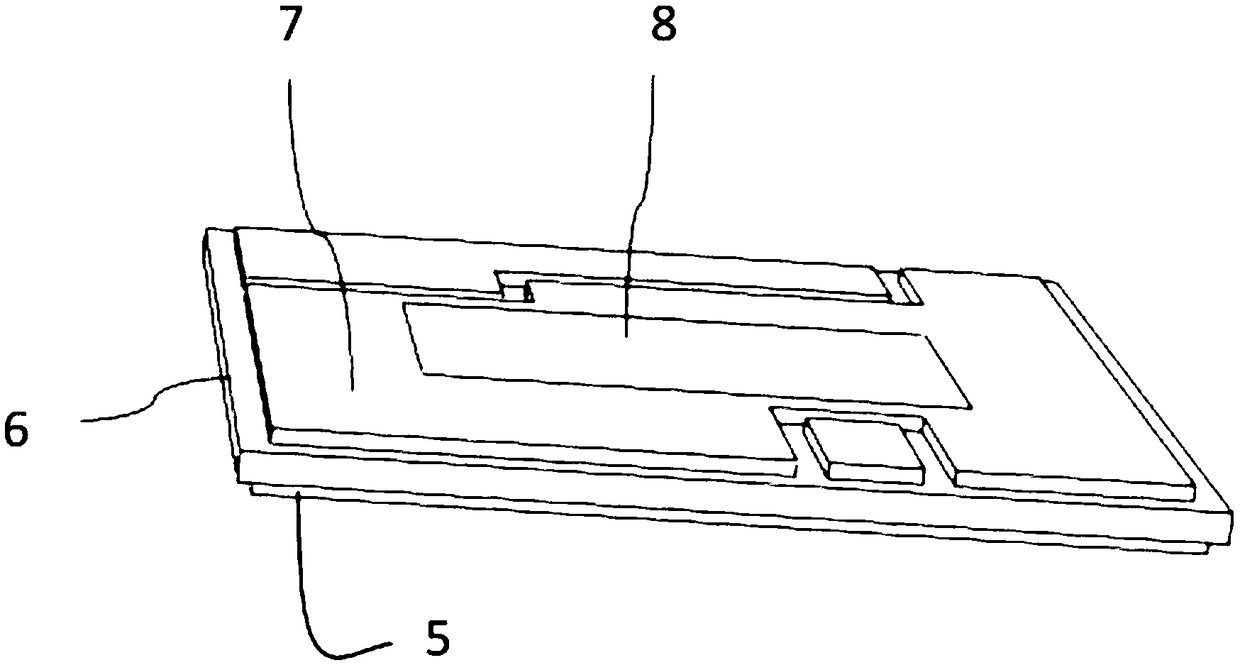

[0028] Below in conjunction with the accompanying drawings, a detailed description will be given of specific implementations based on the uniform current assisted sintering of nano-silver solder paste temperature field on copper-clad ceramic substrates and the rapid sintering connection of IGBT chips / diode chips and copper-clad ceramic substrates (DBC) substrates.

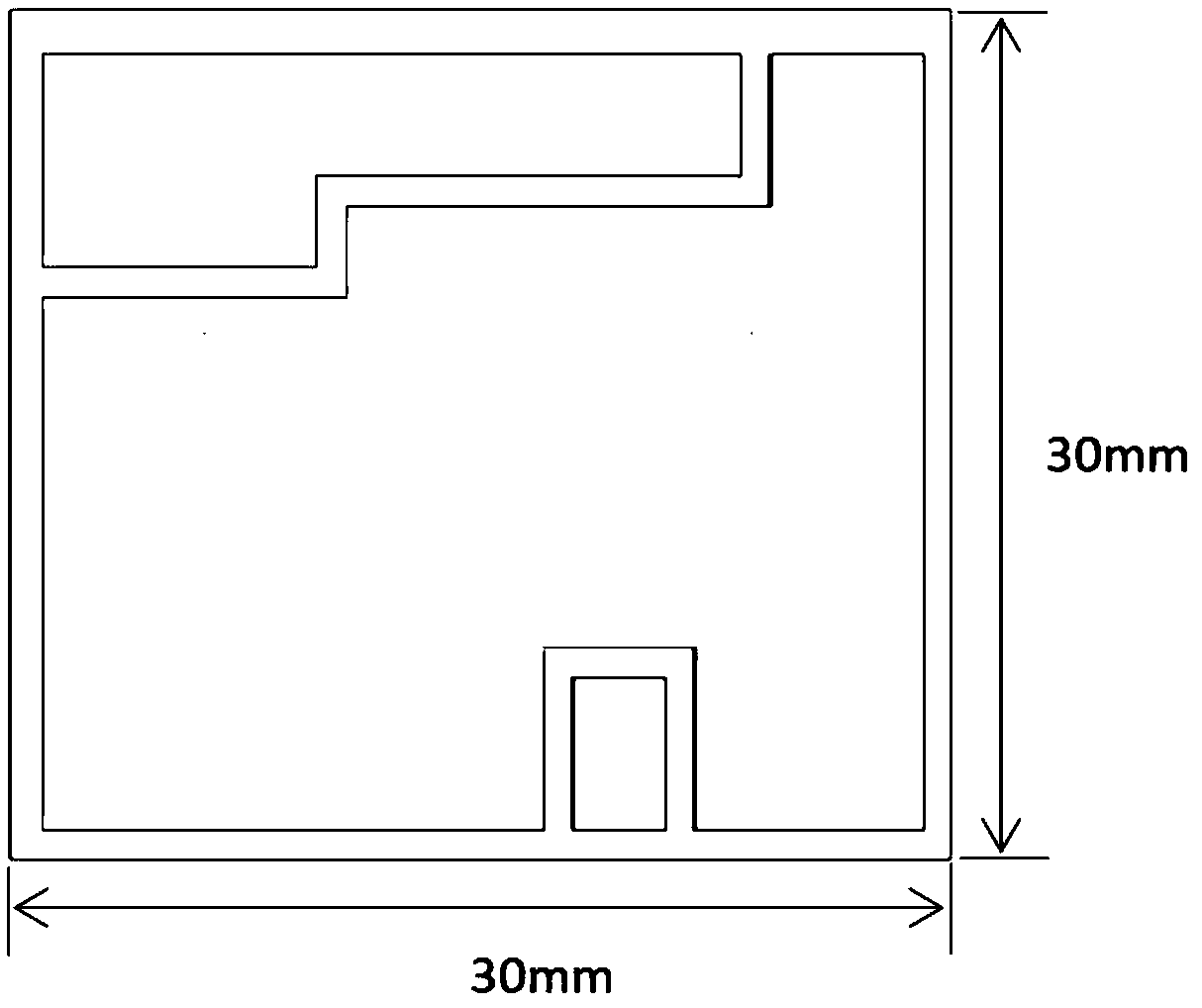

[0029] (1) Before the experiment, place the copper-clad ceramic substrate, chips, and rubber rods in a beaker filled with absolute ethanol, then put them into an ultrasonic cleaner for oscillating cleaning for 10 minutes, and wipe them with dust-free paper after taking them out. The copper-clad ceramic substrate used in the present invention is as figure 1 As shown, the size is 30mm×30mm.

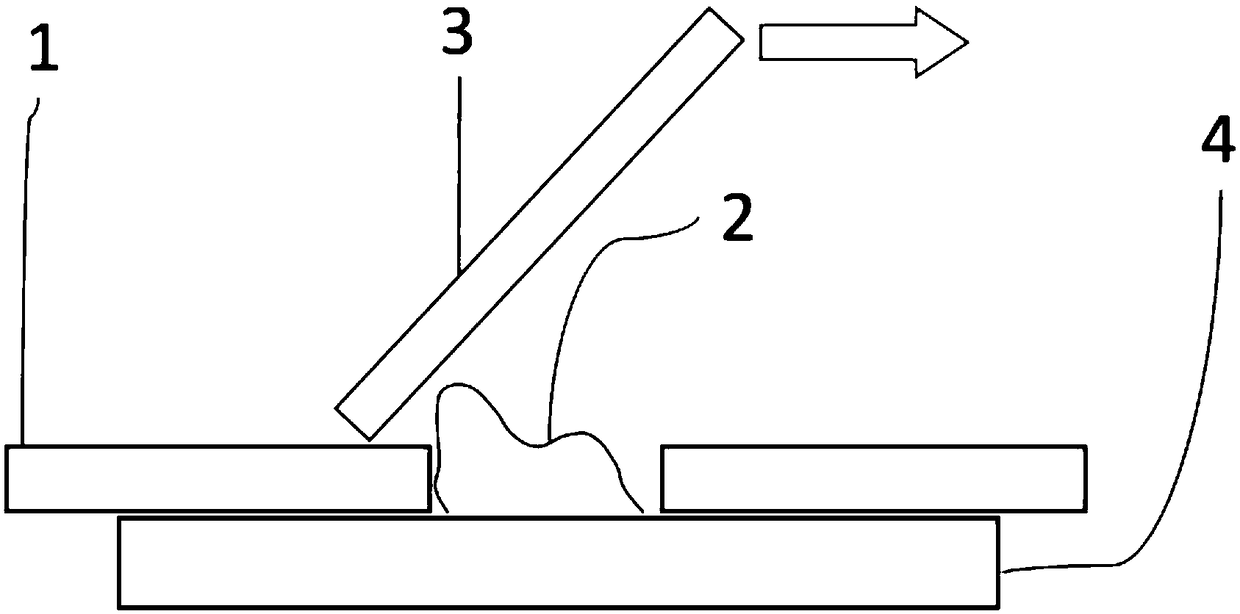

[0030] (2) Printing nano-silver solder paste: according to the chip size, paste four 50μm-90μm thick high-temperature-resistant Kapton tape 1 on the surface of the DBC substrate, and the enclosed area is slightly larger than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com