Production method and system based on stereoscopic storehouse

A production method and production system technology, applied in the field of production systems, can solve problems such as slowness, failure to remove semi-finished products in time, lower production efficiency, and poor production environment, so as to avoid manual handling of materials and semi-finished products, realize automatic control, and improve production environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

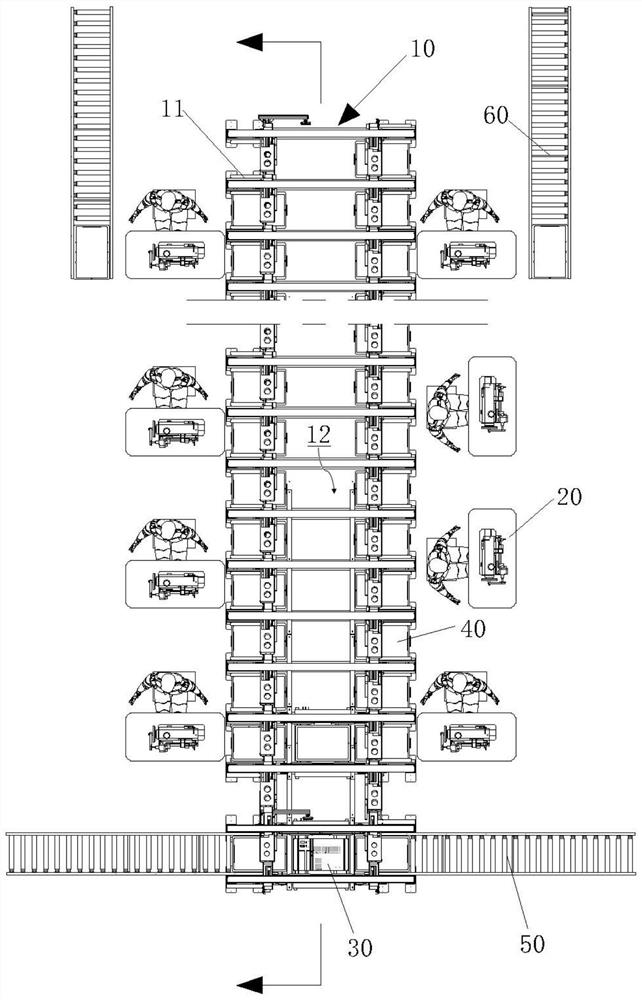

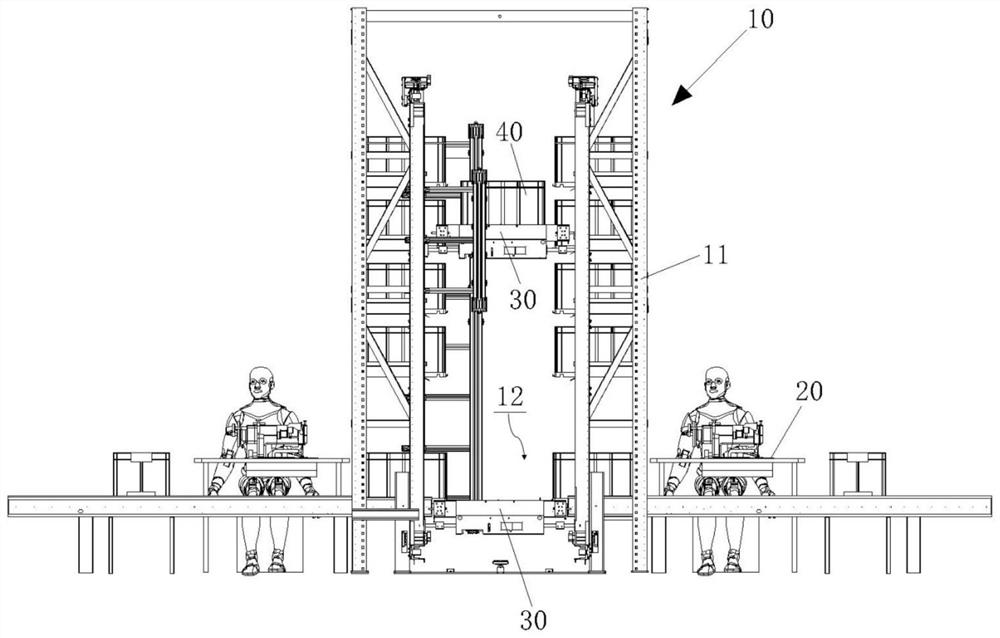

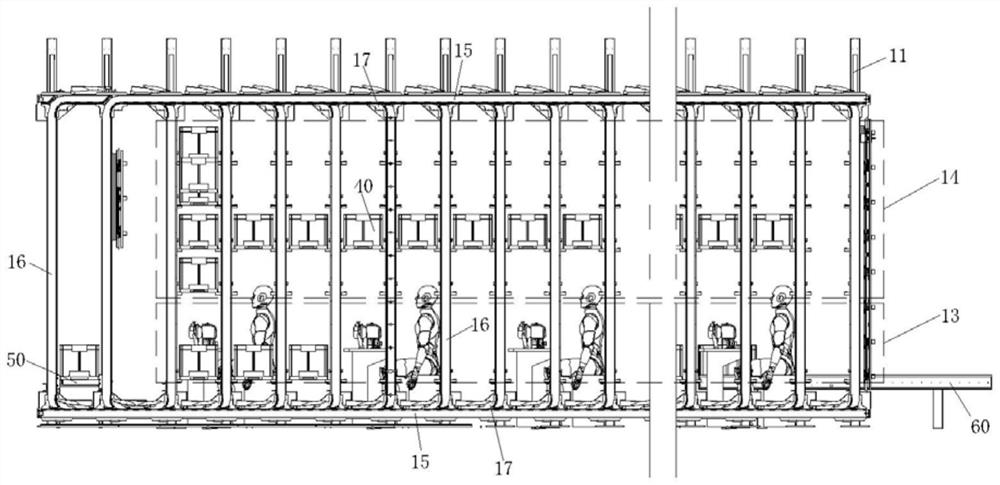

[0027] Such as Figure 1-3 As shown, the production system of the present invention includes a three-dimensional warehouse 10, work stations 20 arranged on both sides of the three-dimensional warehouse 10, and a main control device (such as a computer, a controller and other control devices). The three-dimensional warehouse 10 includes several rows of shelves 11, and a picking channel 12 is arranged between two adjacent rows of shelves 11, and a picking device 30 runs in the picking channel 12. The shelf 11 is provided with storage positions, which are used to store turnover boxes 40 that contain production materials (other loading devices can also be used to hold production materials, such as pallets), and the storage positions are set to be multi-layered and multi-row.

[0028] The warehouse location on the first floor (the lowest floor) is defined as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com