Automatic coil-unloading and shaft-loading device and automatic coil-unloading and shaft-loading method

A technology of automatic unloading and shaft device, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc. It can solve the problems of long time consumption, low degree of automation, and heavy film roll weight, so as to reduce labor intensity and automatically high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

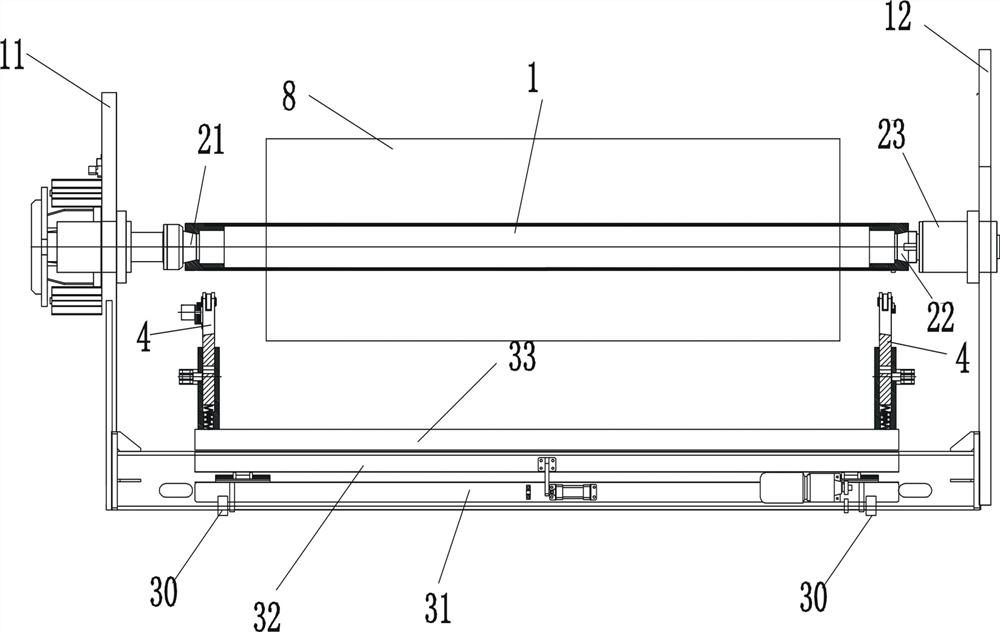

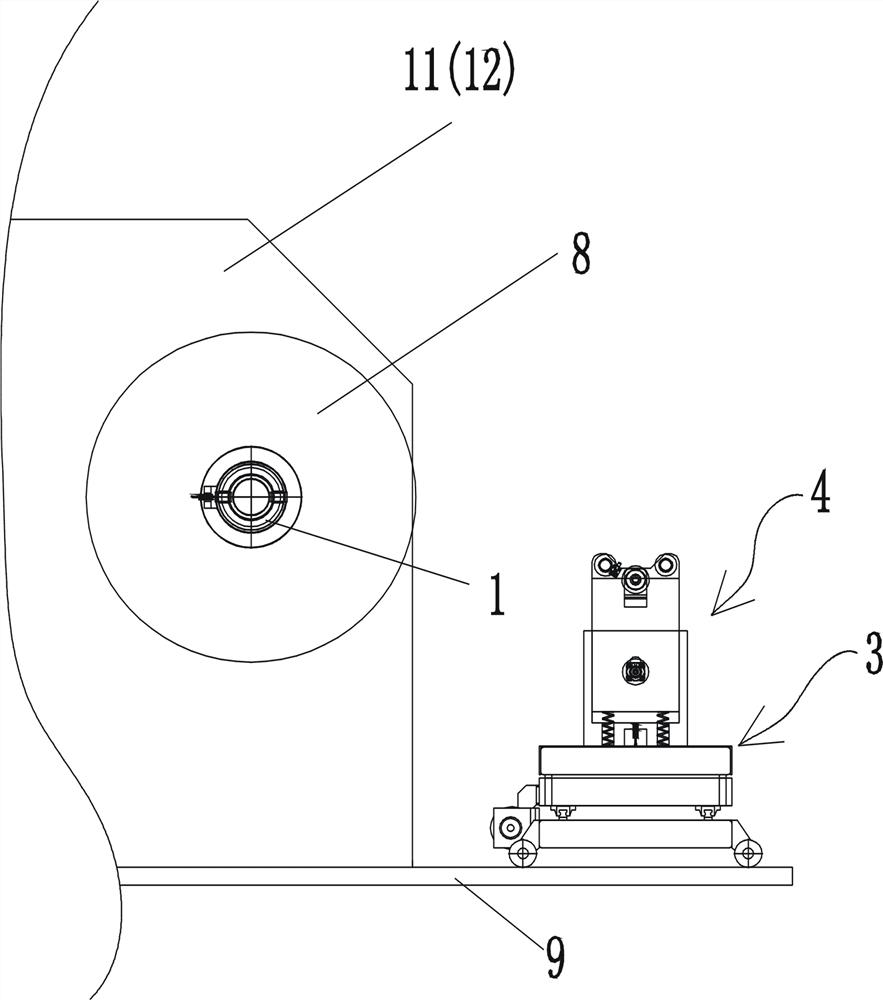

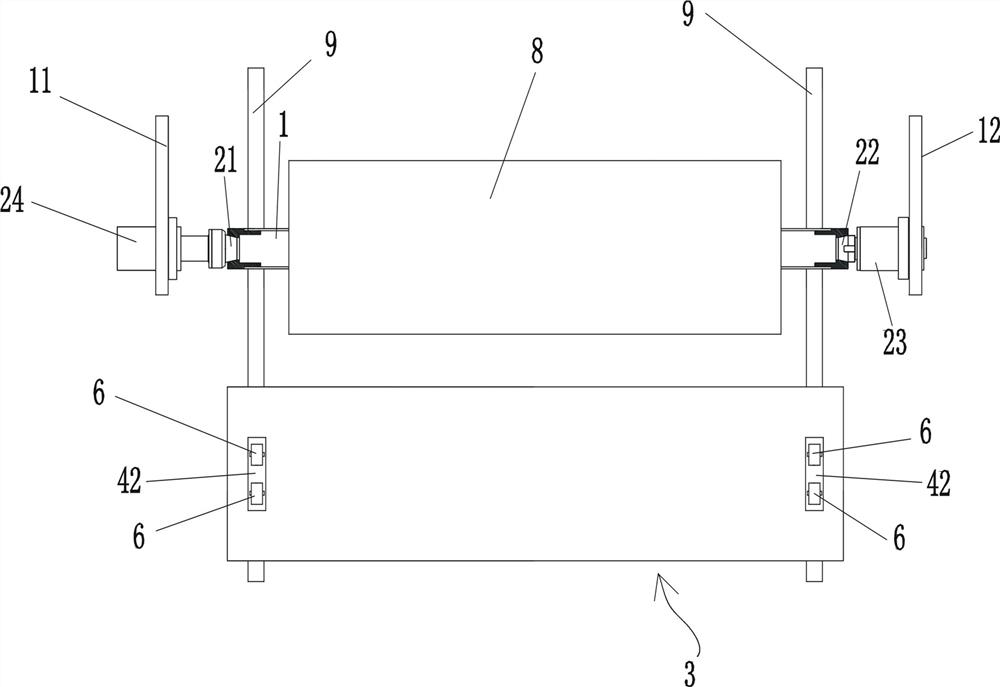

[0066] figure 1 , figure 2 , image 3 As shown, the automatic unwinding shaft device includes a winding shaft 1, a winding support 11 located on the left side of the winding shaft, and a winding support 12 located on the right side of the winding shaft. The central axis of the winding shaft 1 extends laterally, and the left The winding bracket 11 on the side is rotatably equipped with a left plug 21 , and the winding bracket 12 on the right side is rotatably equipped with a right plug 22 . Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, the left and right ends of the winding shaft 1 are respectively provided with tapered sockets 10, and the tapered sockets 10 at the two ends of the winding shaft respectively form a movable plugging relationship with the plugs on the corresponding sides. The axial direction of the reel 1; the rewinding shaft bracket 12 on the right is also provided with a winding motor 23 that drives the right plug to rotate, and the winding sha...

Embodiment 2

[0071] A method for an automatic unloading and winding device, which adopts the automatic unloading and winding device of the first embodiment, and sequentially includes the following steps:

[0072] (1) For normal rewinding, the left plug 21 is inserted into the tapered socket 10 at the left end of the winding shaft, the right plug 22 is inserted into the tapered socket 10 at the right end of the winding shaft, the spline block of the right plug 25 is embedded in the keyway 26 at the right end of the winding shaft, the winding motor 23 drives the right plug 22 to rotate, the right plug 22 drives the winding shaft 1 to rotate, and the winding shaft 1 winds up the plastic film to form a film volume 8; normal winding , the longitudinal position of the carrying trolley 3 is staggered from the longitudinal position of the film roll (of course, the longitudinal position of the carrying trolley 3 is also staggered from the longitudinal positions of the left winding support 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com