A kind of livestock excrement carbonization equipment

A technology of excrement and equipment, which is applied in the field of livestock excrement carbonization equipment, can solve the problems of inconvenient removal, etc., and achieve the effects of convenient use of equipment, environmental protection, and accelerated fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

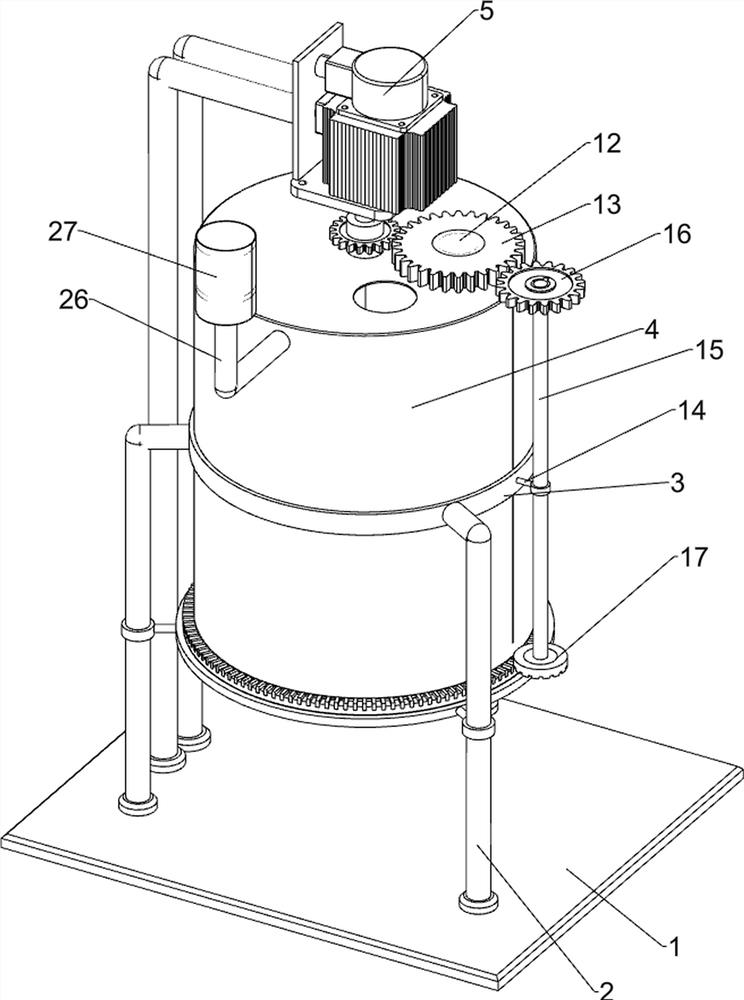

[0021] A carbonization device for livestock excrement, such as figure 1 and 2 As shown, it includes a bottom plate 1, a bracket 2, a ring-shaped fixing frame 3, a heating and discharging barrel 4, a stirring assembly and a discharging assembly. The top of the bottom plate 1 is welded with a bracket 2, and the top of the bracket 2 is fixed with a ring-shaped fixing frame 3 through bolts. The ring fixing frame 3 is fixedly connected with a heating and discharging barrel 4 by bolts, and the heating and discharging barrel 4 is equipped with a stirring assembly for stirring by rotating, and the bottom of the heating and discharging barrel 4 is equipped with a discharging device for discharging by rotating. components.

[0022] When it is necessary to use the device for carbonization of livestock excrement, first place the excrement to be carbonized in the heating discharge barrel 4, then control the heating discharge barrel 4 to start heating, and at the same time control the stir...

Embodiment 2

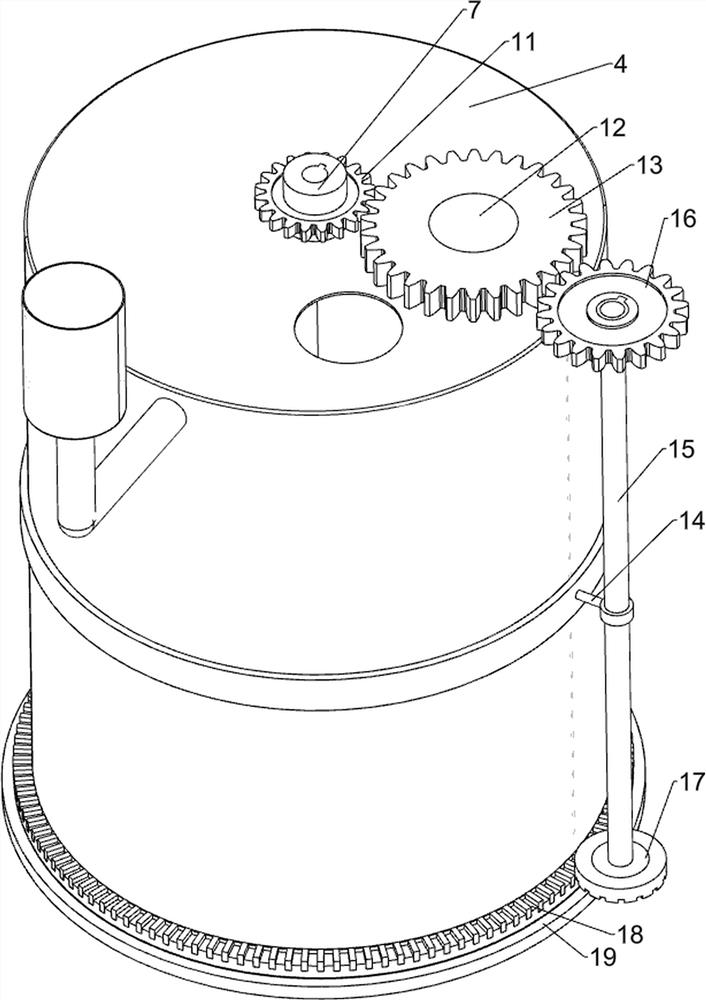

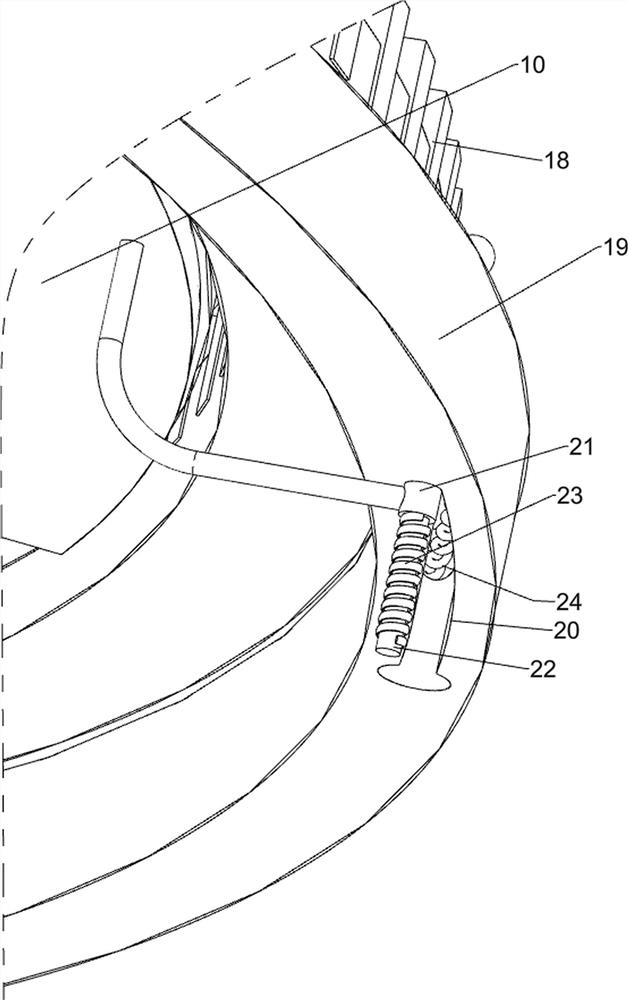

[0028] On the basis of Example 1, such as figure 1 , 3 , 4, 5 and 6, also includes a first gear 11, a first connecting shaft 12, a second gear 13, a first connecting rod 14, a second connecting shaft 15, a third gear 16, a fourth gear 17, Ring gear 18, second annular plate 19, hollow rod 21, guide rod 22, tension spring 23, arc spring 24 and contact plate 25, the first gear 11 is connected with the key on the top of the transmission shaft 7, and the top right of the heat discharge barrel The side is provided with a first connecting shaft 12 through the rotation of the bearing seat, the top of the first connecting shaft 12 is keyed to a second gear 13, the second gear 13 meshes with the first gear 11, and the right side of the ring fixing frame 3 is welded with the first connecting shaft. Rod 14, the right end of the first connecting rod 14 is rotatably provided with a second connecting shaft 15 through a bearing seat, the top end of the second connecting shaft 15 is keyed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com