Apparatus and method for carbonization treatment of brake pad lining surface

A surface carbonization and treatment device technology, applied in friction linings, mechanical equipment, etc., can solve the problems of unguaranteed product carbonization quality, uncontrollable temperature, high energy consumption of heating devices, etc., to achieve the best braking effect, reduce Energy consumption, effect of improving carbonization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

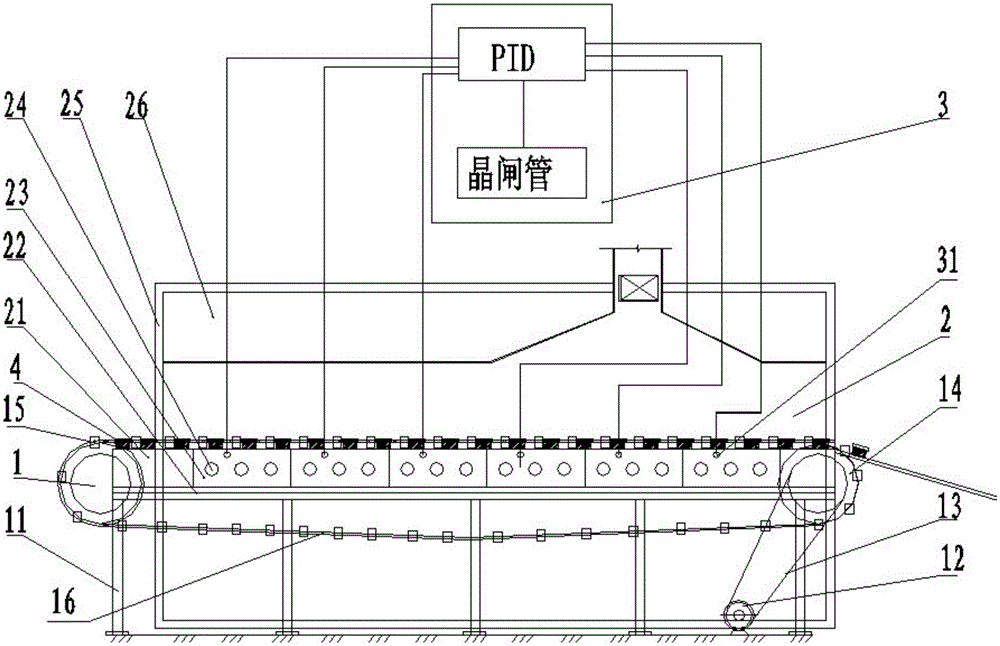

Image

Examples

Embodiment 1

[0032] Step 1: Turn on the resistance heater 24 and the temperature control system 3, and set the temperature of the heating steel plate 23 in the carbonization chamber to 500°C.

[0033] Step 2: Start the speed-regulating motor 12 of the metal chain conveyor 1, and control the running speed of the chain feed block 15 to 3 meters per minute.

[0034] Step 3: When the temperature of the heating steel plate 23 in the carbonization chamber 2 reaches the set temperature, place the brake pad 4 on the stock steel plate 21, start the speed regulating motor 12, the sprocket drum 14 rotates, and the sprocket drum 14 drives the chain When the wheel rotates, when the sprocket is driving, the chain feed block 15 between the two chains 16 is moved forward and brought into the carbonization chamber. It is placed on the stock steel plate 21 and is located between the two chain feed blocks 15 and the brake pad 4 follows The chain feed block 15 enters the carbonization chamber, and the brake pad 4 ...

Embodiment 2

[0037] A surface carbonization treatment method for disc brake pad linings, repeating the steps in the above embodiment 1, but the treatment conditions set are different as follows:

[0038] The heating steel plate 23 in the carbonization chamber is set to a temperature of 550°C, and the running speed of the chain feed block 15 is controlled at 3.5 m / min.

Embodiment 3

[0040] A surface carbonization treatment method for disc brake pad linings, repeating the steps in the above embodiment 1, but the treatment conditions set are different as follows:

[0041] The heating steel plate 23 in the carbonization chamber is set to a temperature of 600° C., and the running speed of the chain feed block 15 is controlled at 4 m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com