Halogen-free flame-retardant nylon material and preparation method thereof

A technology of flame retardant nylon and flame retardant, applied in the field of halogen-free flame retardant nylon materials and its preparation, can solve the problems of polluting mold production, reducing production efficiency, increasing cooling time, etc., to accelerate carbonization speed, improve work efficiency, Cooldown reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

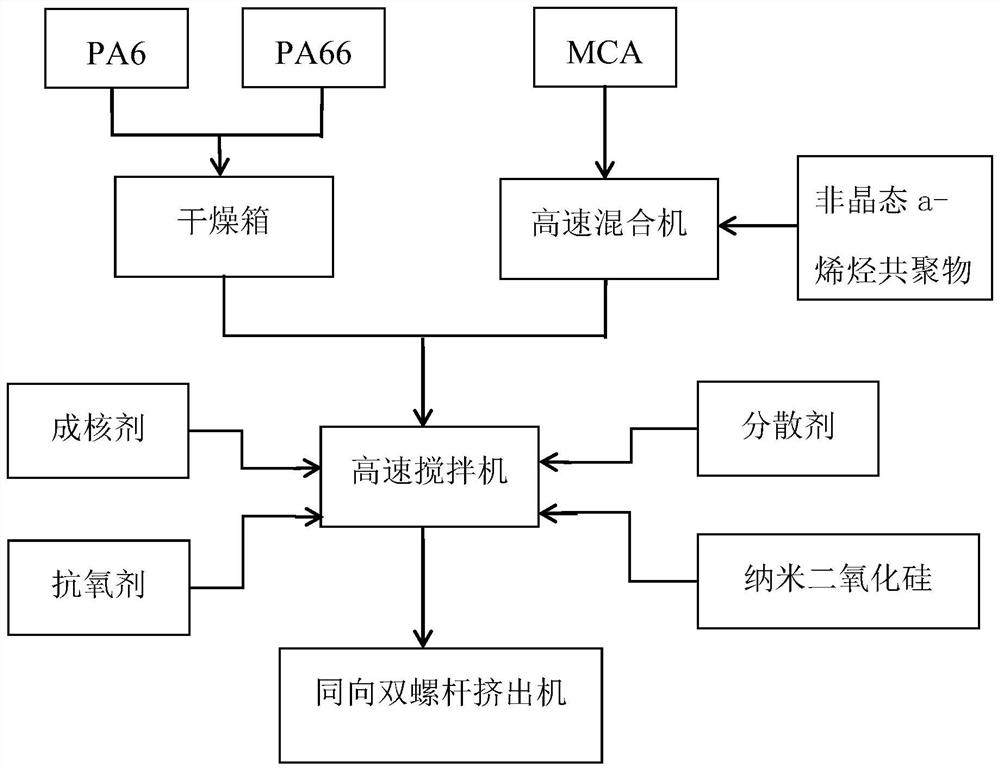

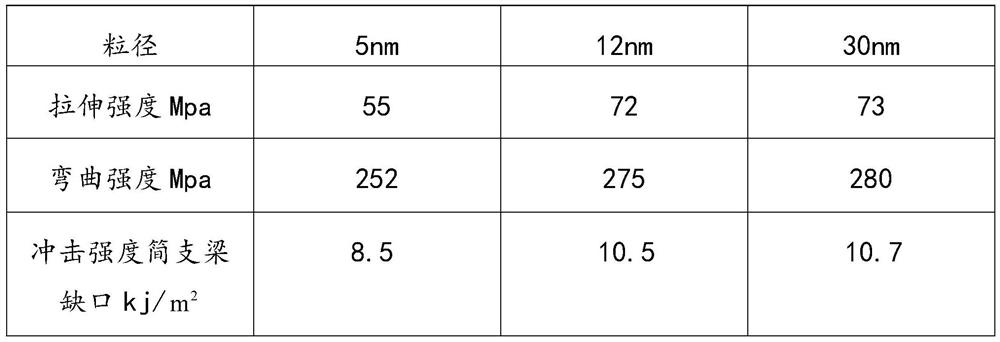

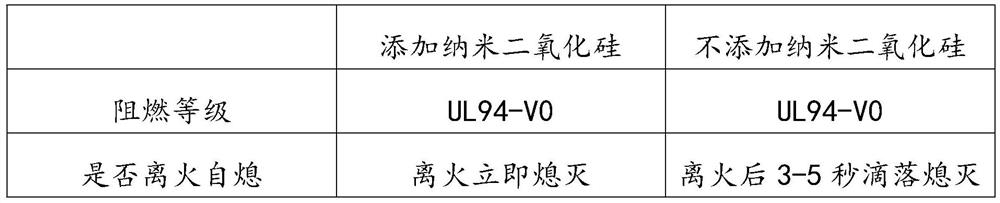

[0037] Such as figure 1 As shown, a halogen-free flame-retardant nylon material is prepared from the following raw materials in parts by weight: 5.7 parts of PA668, 5 parts of PA6, 0.2 parts of antioxidant, 0.2 parts of dispersant, and 0.5 parts of synergistic combustion enhancer 0.2 parts, 0.2 parts of nucleating agent, 8 parts of MCA flame retardant, 0.2 parts of amorphous a-olefin copolymer emulsion, synergistic combustion promoter is nano-silica, the particle size of nano-silica is controlled at 5-30nm, Among them, the influence of the particle size of nano-silica on the physical properties of halogen-free flame-retardant nylon materials is shown in the table below. When the particle size of nano-silica is controlled at 30nm, the tensile strength, bending strength and impact strength of nylon materials Charpy notched has the best physical properties.

[0038]

[0039] In this embodiment, the model of the high-speed mixer is SHR-100a, the model of the high-speed mixer i...

Embodiment 2

[0056] Such as figure 1 As shown, a halogen-free flame-retardant nylon material is prepared from the following raw materials in parts by weight: 5.7 parts of PA668, 5 parts of PA6, 0.2 parts of antioxidant, 0.2 parts of dispersant, and 0.5 parts of synergistic combustion enhancer 0.2 parts, 0.2 parts of nucleating agent, 8 parts of MCA flame retardant, 0.2 parts of amorphous a-olefin copolymer emulsion, synergistic combustion promoter is nano-silica, the particle size of nano-silica is controlled at 50-90nm, Among them, the effect of the particle size of nano-silica on the physical properties of halogen-free flame-retardant nylon materials is shown in the table below. When the particle size of nano-silica is controlled at 70nm, the tensile strength, bending strength and impact strength of nylon materials Charpy notched has the best physical properties.

[0057]

[0058] In this embodiment, the model of the high-speed mixer is SHR-100a, the model of the high-speed mixer is ...

Embodiment 3

[0074] Such as figure 1 As shown, a halogen-free flame-retardant nylon material is prepared from the following raw materials in parts by weight: 5.7 parts of PA668, 5 parts of PA6, 0.2 parts of antioxidant, 0.2 parts of dispersant, and 0.5 parts of synergistic combustion enhancer 0.2 parts, 0.2 parts of nucleating agent, 8 parts of MCA flame retardant, 0.2 parts of amorphous a-olefin copolymer emulsion, synergistic combustion promoter is nano-silica, the particle size of nano-silica is controlled at 120-150nm, Among them, the influence of the particle size of nano-silica on the physical properties of halogen-free flame-retardant nylon materials is shown in the table below. When the particle size of nano-silica is controlled at 120nm, the tensile strength, bending strength and impact strength of nylon materials Charpy notched has the best quality of physical properties.

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com