Microbial grouting and anchoring method and structure for installing partitions in a cavity to form pipelines

An anchoring method and microbial technology, applied in building structures, building components, covering/lining, etc., can solve problems such as increasing construction difficulty, pipeline blockage, increasing borehole diameter, etc., achieving simple and convenient operation and construction, reducing diameter size, The effect of enhancing the anchoring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In a typical embodiment of the present invention, such as Figure 1-Figure 8 As shown, a microbial grouting anchoring method is proposed in which a partition is set in the cavity to form a pipeline.

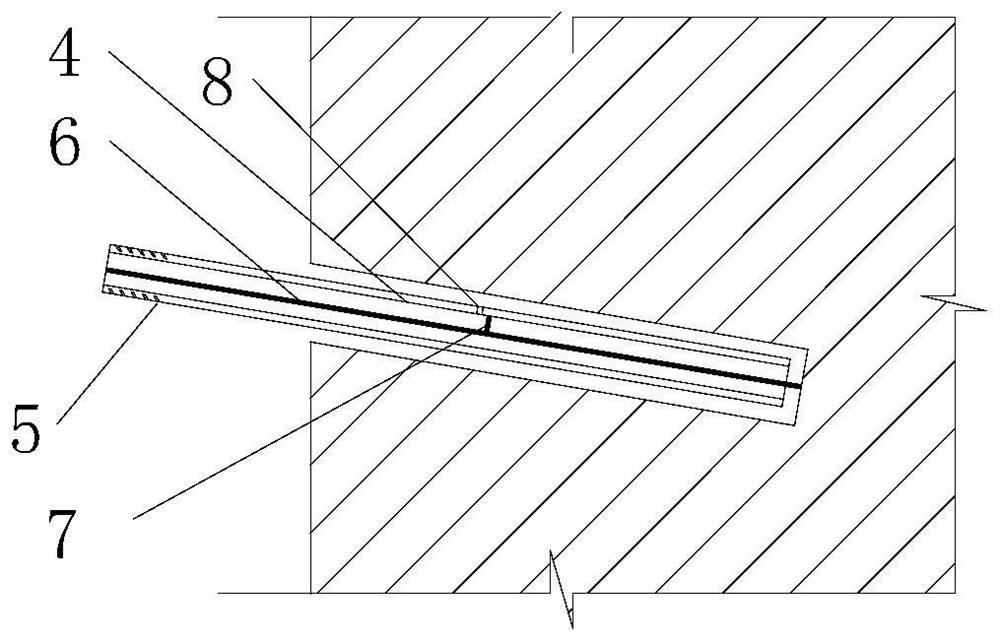

[0046] First, the anchor member used in this method is composed of a hollow anchor rod (in this embodiment, a hollow screw 4 with an inner partition) and a nut 21, and the anchoring section of the hollow screw 4 with an inner partition extends into the anchor matrix In the borehole 2 of 1, the free section of the hollow screw rod 4 with an inner partition is provided with a threaded buckle 5 and is tightly connected with the nut 21.

[0047] The steps of its anchoring method are:

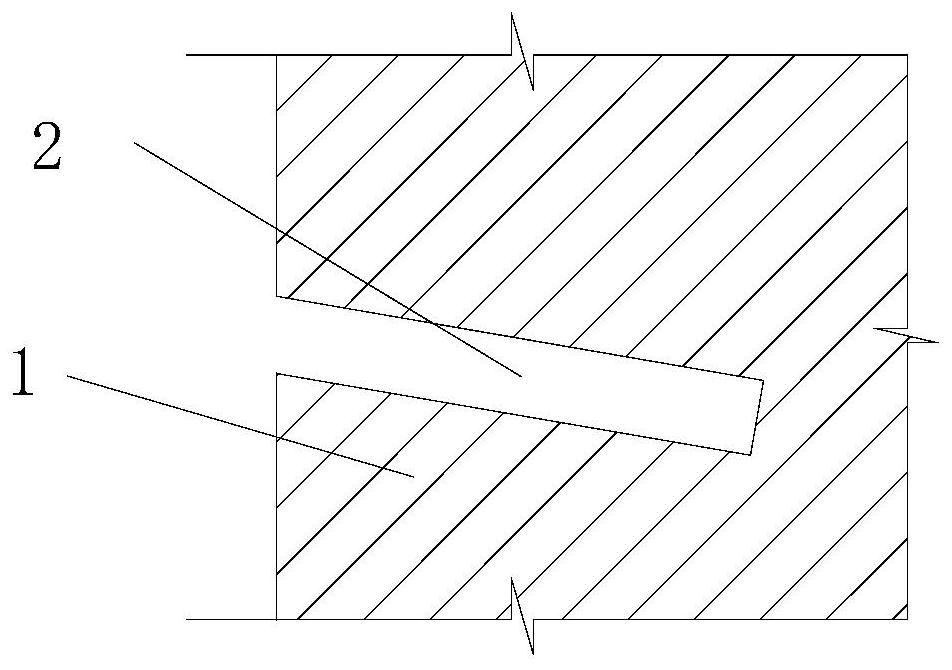

[0048] Step 1, first drill holes on the anchorage substrate 1 such as the wall, such as figure 1 Shown; the diameter of the borehole 2 is 2 to 3mm larger than the hollow screw of the anchoring member, so as to fill the screw.

[0049] The borehole is inclined downward, and the angle with the ...

Embodiment 2

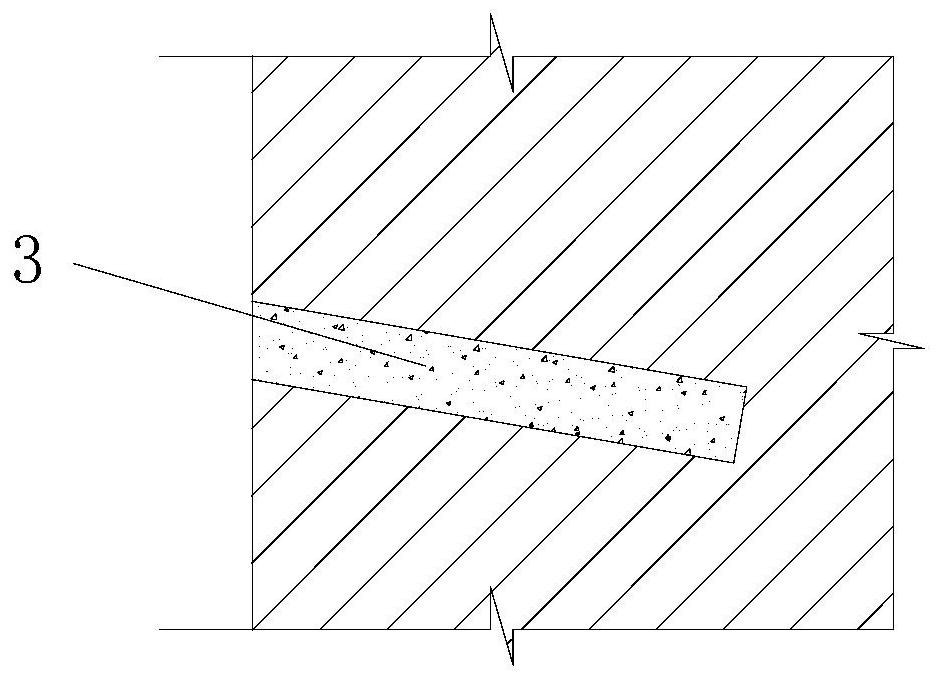

[0077]This embodiment provides a microbial grouting anchorage structure, such as Figure 7 Shown, comprise hollow anchor rod (here is the hollow screw rod 4 of band interior partition), hollow anchor rod has hollow cavity, horizontal inner partition and vertical inner partition are arranged in the hollow cavity of hollow anchor rod The plate, the horizontal inner partition and the vertical inner partition are perpendicular to each other, and the cavity of the hollow anchor rod is divided into four pipes for grouting. The hollow cavity of the hollow anchor rod is provided with a central diaphragm along the radial direction. The partition blocks two of the pipes, the middle of the hollow anchor rod is provided with a side hole connecting the hollow cavity, the hollow screw extends into the borehole 2 of the anchoring matrix 1, and the carbon dioxide induced by microorganisms is placed between the borehole and the hollow screw. Calcium cement body 22, the side wall of the anchori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com