Steel tube tower for preventing breeze vibration

A steel tube tower, breeze technology, applied in the direction of towers, shockproof, building components, etc., can solve the problems of fatigue failure of connecting plates, loose bolt connections, etc., and achieve the effects of preventing breeze vibration, convenient construction and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

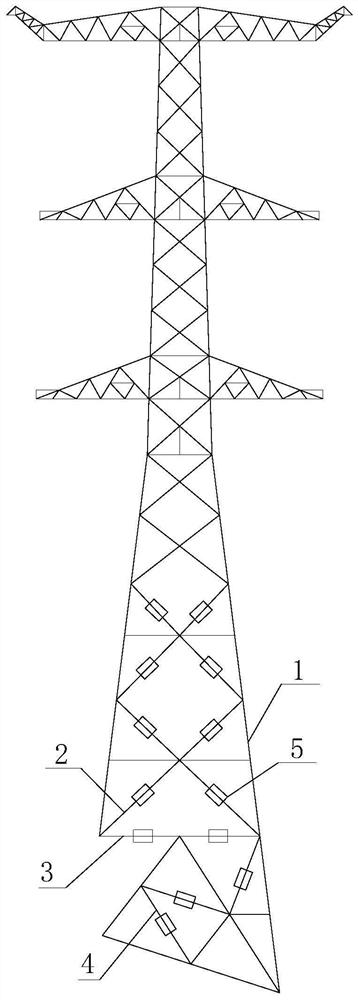

[0017] refer to figure 1 The specific embodiment of the present invention is that several irregular spoilers 5 are respectively welded on the cross member 2 of the lower part of the tower body of the steel pipe tower body 1, the horizontal partition member 3 and the leg V-surface member 4, which are used to disturb the wind around the wind. The vortex formed after passing the rod prevents the occurrence of breeze vibration of the rod. This form is suitable for new steel pipe tower structures.

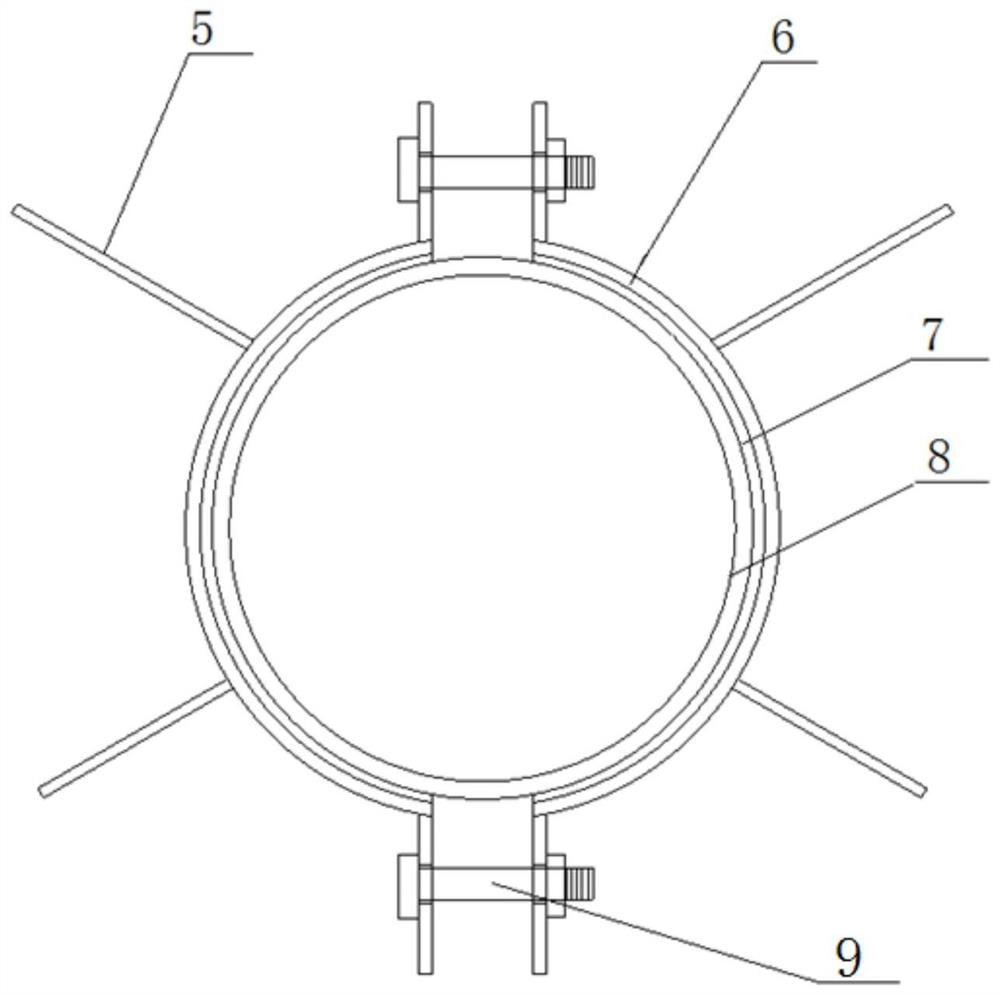

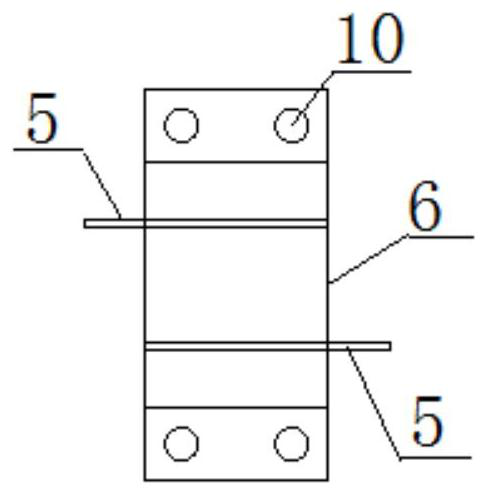

[0018] refer to figure 2 , For the completed project, the fixture installation is adopted. That is, the irregular spoiler 5 is connected to the split fixture 6, the thickness of the fixture is 3-5mm, and the size is determined according to the specific rod diameter. The spoiler is fixed on the rod by the clamp, which is convenient for installation, disassembly and adjustment, and it is convenient to adjust the shape, quantity and size of the spoiler according to the wind speed and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com