Corner decorative glass plate for disinfection cabinet and manufacturing method thereof

A manufacturing method and glass plate technology, which is applied in the field of disinfection cabinets, can solve problems such as glass plate bursting, poor thermal insulation and sound insulation, and glass bumps, and achieve the effects of improving strength, improving connection effects, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

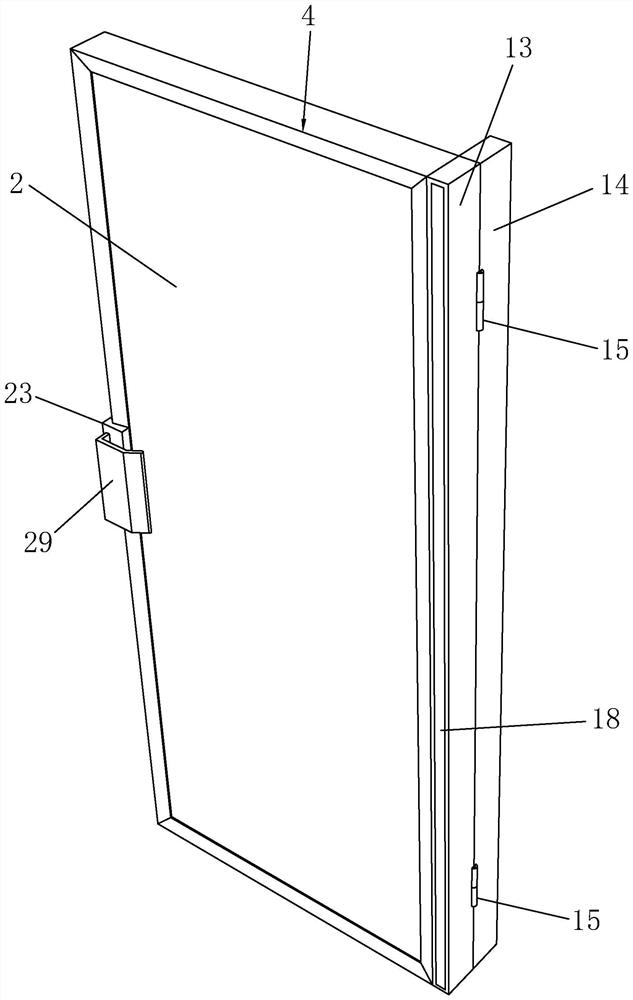

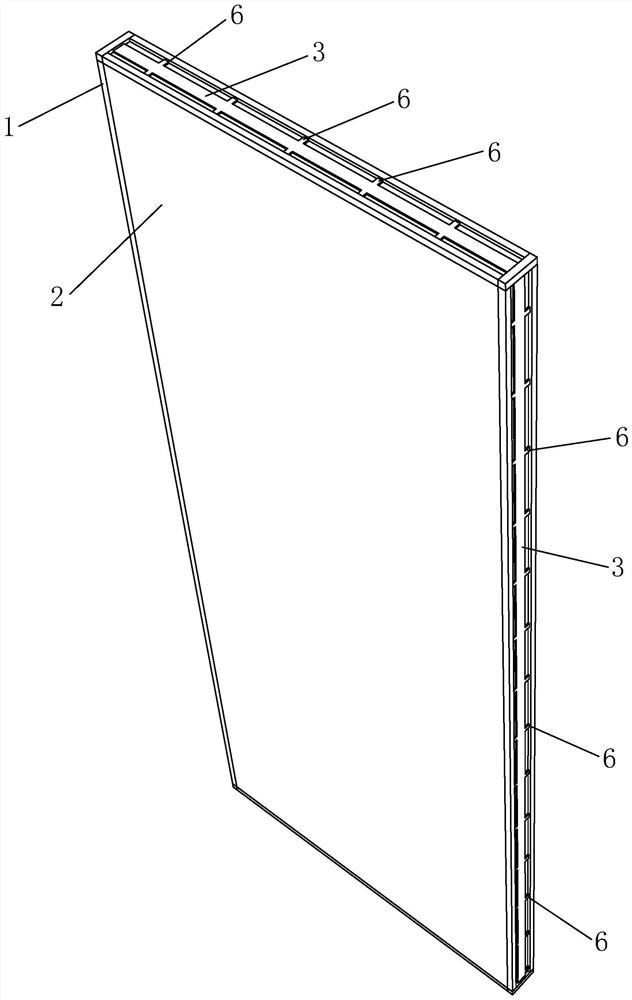

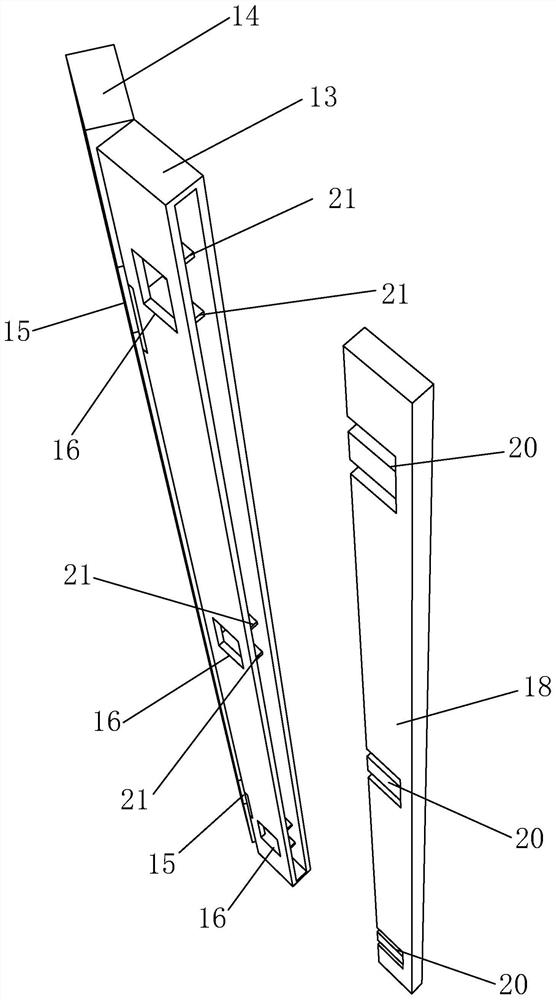

[0037] like Figure 1 to Figure 7 As shown, it is a corner decorative glass plate for a disinfection cabinet of the present invention, comprising a fixed frame 1 and two fixed plates 2, the fixed plate 2 is arranged in the fixed frame 1, and a fixed plate 2 is provided between the two fixed plates 2. bar 3, the fixing bar 3 is arranged on the fixing frame 1, the fixing frame 1 is provided with an outer frame 4, the outer frame 4 is arranged on the outer side of the fixing frame 1, the fixing frame 1 is provided with a fixing hole 5, and the fixing bar 3 is arranged in the fixing hole 5 In the middle, the fixing bar 3 is provided with a limit rod 6 , and the limit rod 6 is clamped on the fixing hole 5 . By fixing the fixing plate 2 made of glass in the fixing frame 1, the direct bumping of the fixing plate 2 can be effectively reduced, and the damage of the fixing plate 2 can be avoided. At the same time, the fixing frame 1 can make the two fixing plates 2 form an insulating gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com