Override-mode magnetic levitation energy-saving-type air blower

A magnetic levitation and blower technology, which is applied to mechanical equipment, non-displacement pumps, non-variable pumps, etc., can solve the problems of high energy consumption and the inability of the blower to switch to neutral, so as to save energy, increase the service life, eliminate The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

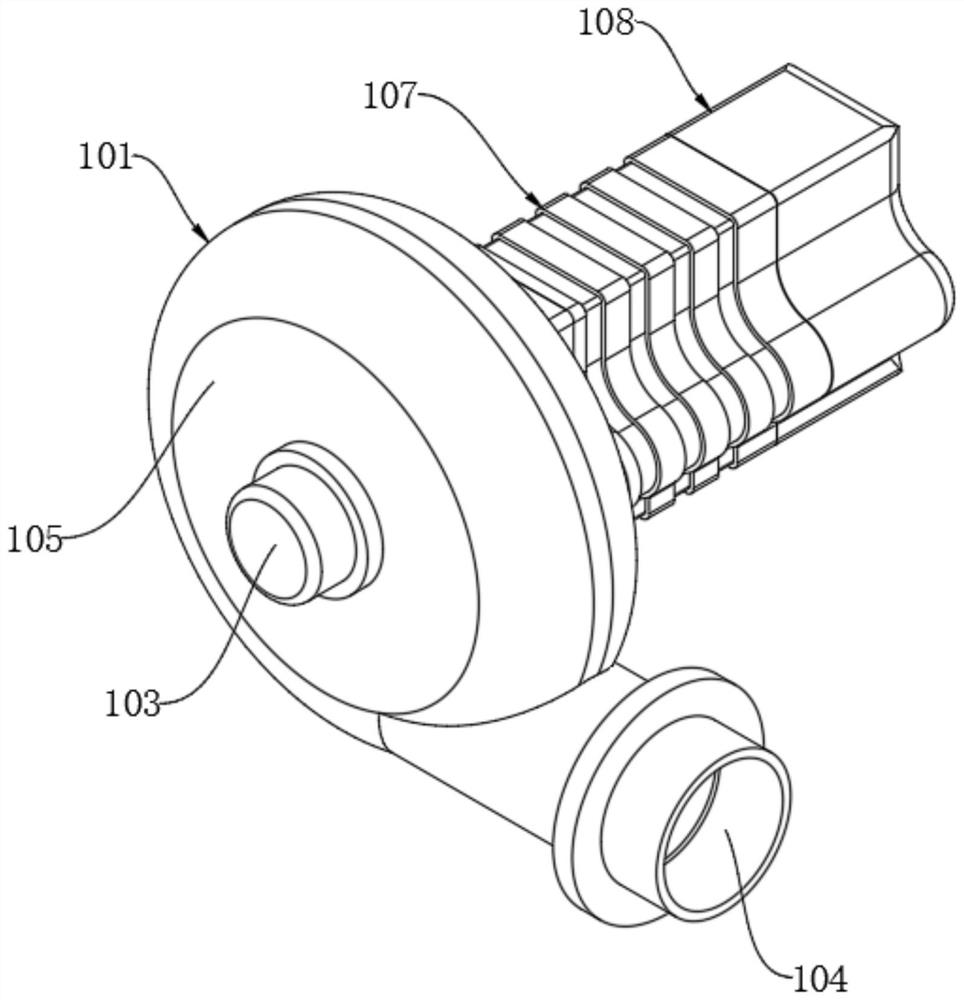

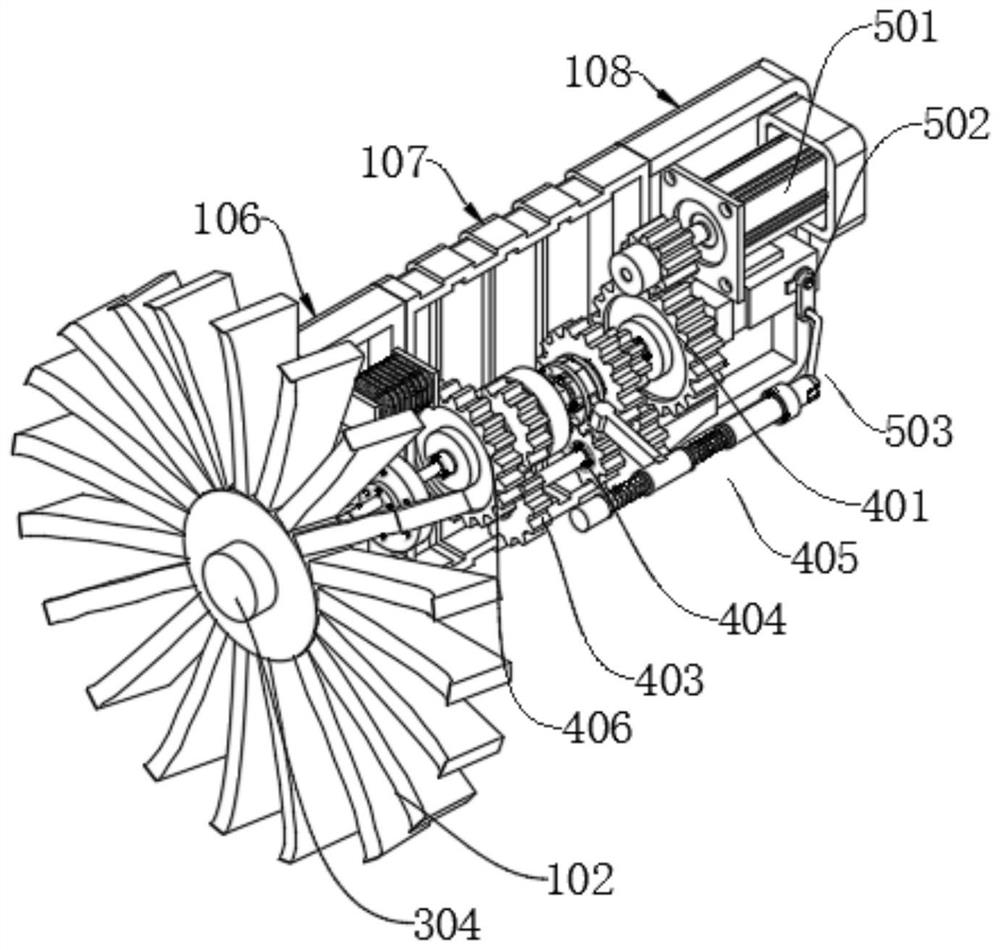

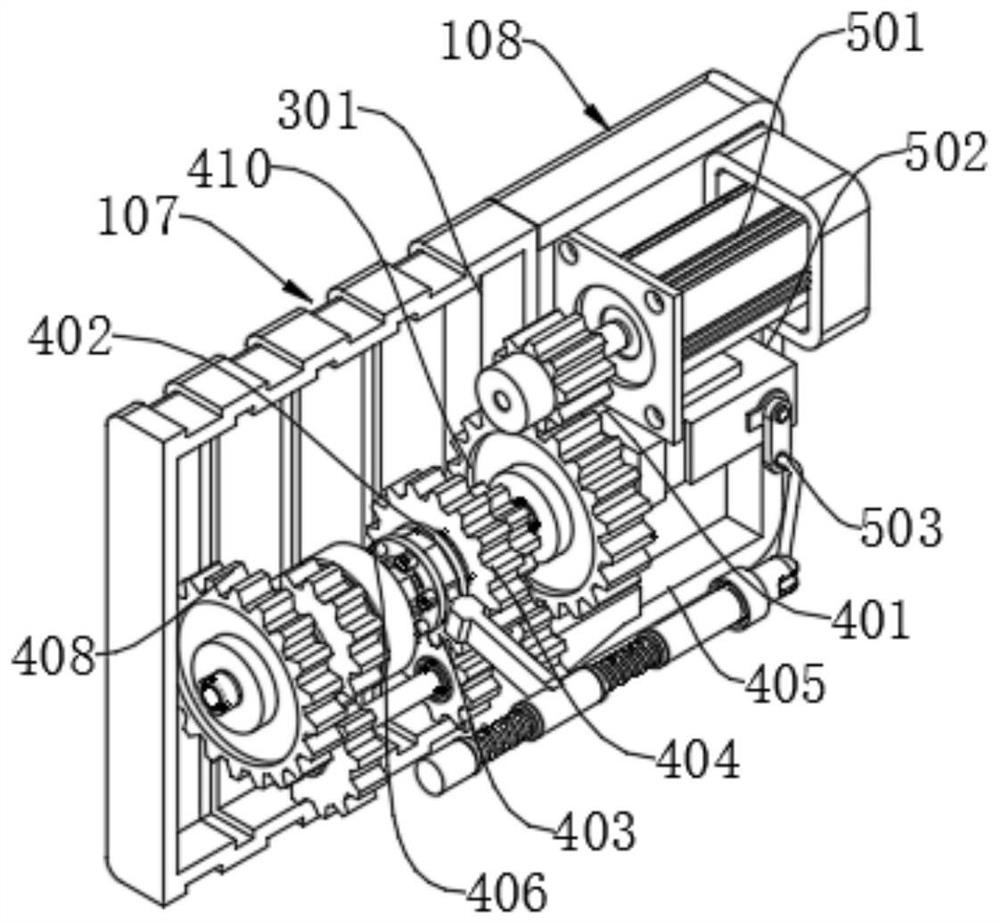

[0025] refer to Figure 1-5 , a maglev energy-saving blower in override mode, comprising: a blower body 101, a maglev idling module 106, an automatic gearbox 107 and a drive module 108, the right side of the blower body 101 is fixedly connected to the maglev idling module 106, and the right side of the maglev idling module 106 It is fixedly connected with the automatic transmission 107, and the right side of the automatic transmission 107 is fixedly connected with the drive module 108;

[0026] Blower body 101 includes: rotor blade 102, air inlet 103, air outlet 104 and cylinder 105, rotor blade 102 is fixedly installed inside cylinder 105, air inlet 103 and air outlet 104 are arranged on cylinder 105, rotor blade 102 and maglev idling module 106 fixed connections.

[0027] The air inlet 103 is externally connected with an air filter.

[0028] The magnetic levitation idling module 106 includes: a liquid-cooled housing 301, an electromagnet 302, a rotor coil 303 and a connect...

Embodiment 2

[0032] Embodiment 2: the difference based on embodiment 1 is;

[0033]The liquid-cooled shell 301 is used to cool down the permanent magnet motor 501 and the magnetic levitation idling module 106, which effectively increases the service life of the device, and in order to effectively save energy consumption, it adopts automatic gear switching, and the running time at one end reaches the specified time. After the target enters the idling state, after entering the idling state, the friction generated during the rotation process can be effectively eliminated by the magnetic levitation idling module 106 to achieve the energy-saving effect. During the switching process, the switching link 503 is driven by the switching motor 502 to drive the shift The rod 405 moves, drives the shift fork 404 to move on the spline shaft 402, and is separated from the output gear set 401, and then enters the idling mode, in which the permanent magnet motor 501 can be turned off, and the friction is el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com