A method for setting the temperature curve of reflow oven for multi-variety and small batch

A temperature curve, small batch technology, applied in CAD circuit design, design optimization/simulation, computer-aided design, etc., to reduce costs, improve confidence, and low implementation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

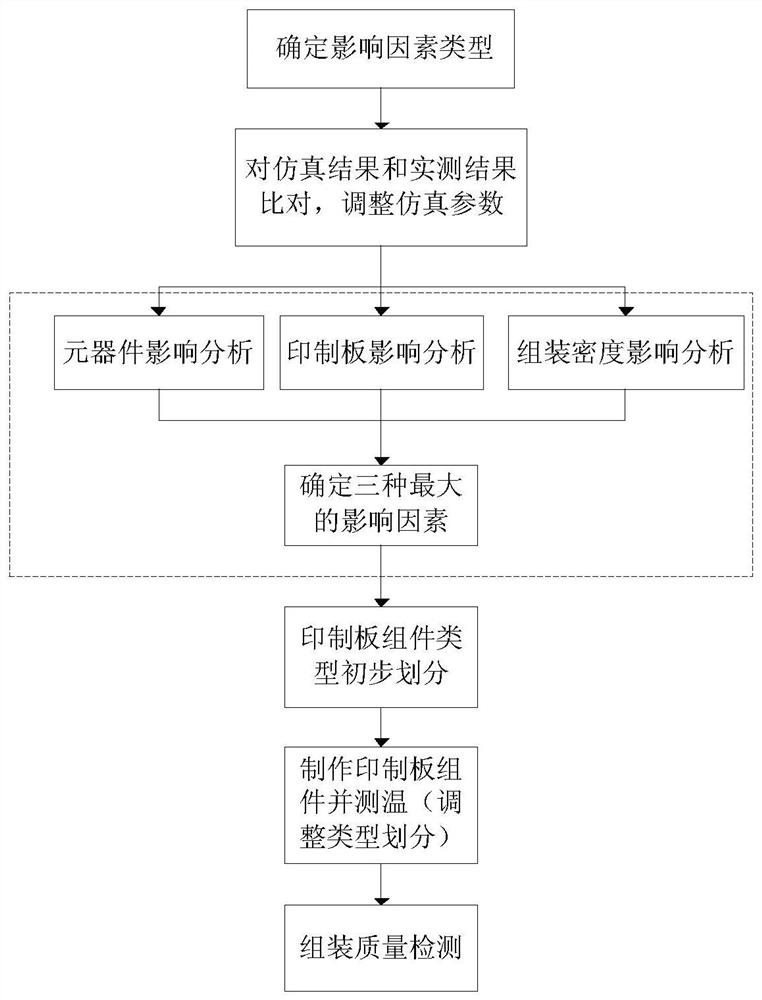

[0020] A method for setting the temperature curve of a reflow oven for multi-variety and small batches, comprising the following steps:

[0021] Step 1: Analyze the influence of the characteristic factors of the printed board assembly on the reflow soldering temperature curve under a standard heating condition.

[0022] Step 2: According to the strength of the influencing factors, the types of printed board components are divided according to the actual application, and the preliminary classification is carried out. In the preliminary classification, printed board components are divided into several categories, and each category is subdivided into several subcategories;

[0023] Step 3: Set a corresponding reflow program for each category after division, and use the printed board components with corresponding characteristics to measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com