AGV-containing personalized customization flexible job shop scheduling method

A flexible operation and workshop scheduling technology, applied in the field of Internet of Things, can solve complex problems and achieve the effect of efficient collaboration methods, equipment utilization and energy consumption advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

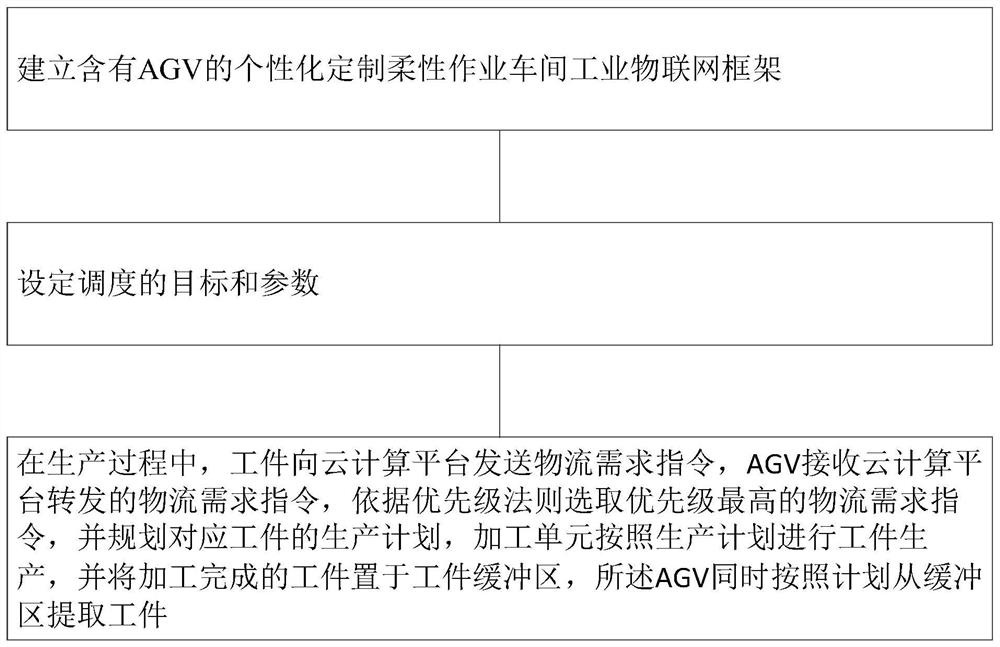

[0037] refer to figure 1 , the present invention provides a kind of personalized customized flexible job shop scheduling method containing AGV, including:

[0038] Establish a personalized customized flexible job shop industrial Internet of Things framework containing AGV; the flexible job shop industrial Internet of Things framework includes at least a cloud computing platform connected through a 5G communication network, computing resources deployed at the edge of the processing unit and AGV, communication equipment and RFID equipment installed on sensors and workpieces;

[0039] By deploying 5G communication network and cloud computing platform in the factory, deploying edge computing resources, communication equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com