Resonator

A resonator and resonant region technology, applied in the field of resonators, can solve the problems of Q value reduction, dissipation, and composite film discontinuity at the anti-resonance point, and achieve the effect of improving Q value and reducing transverse wave resonance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

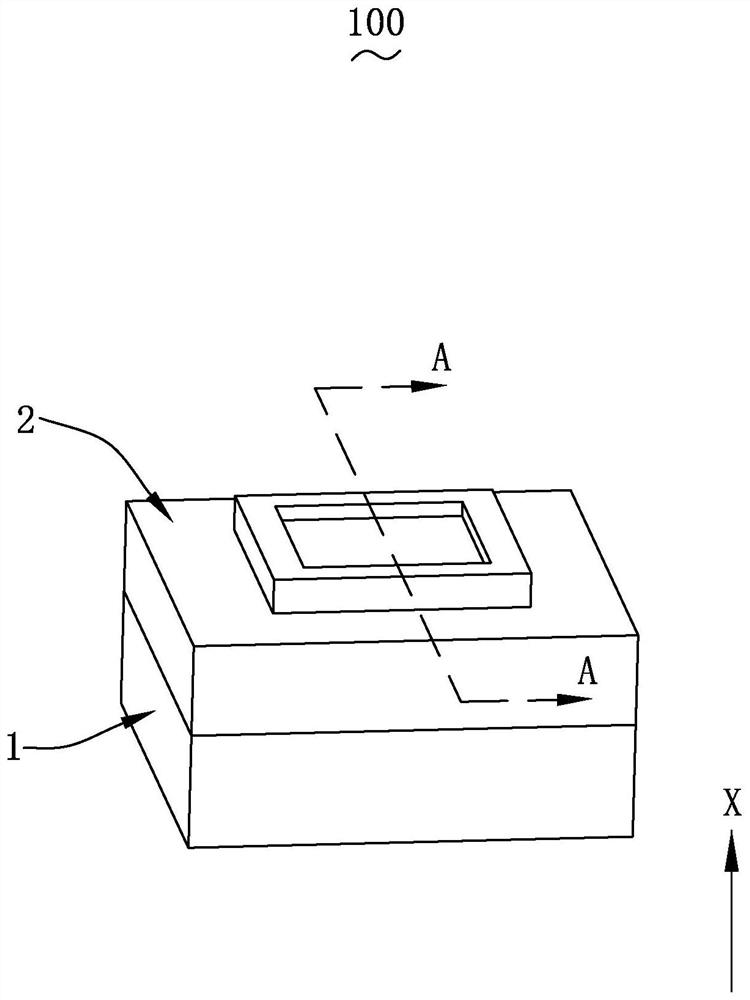

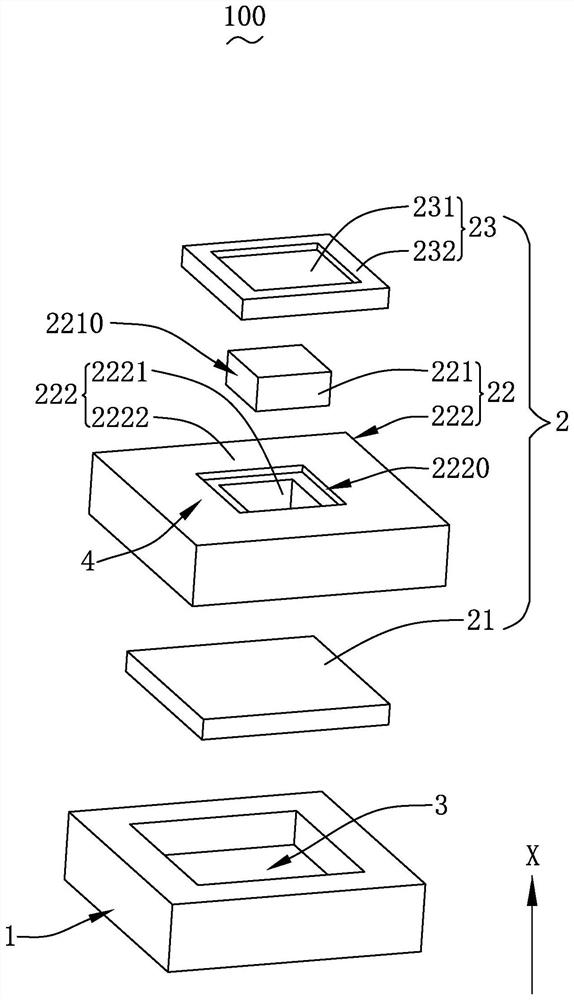

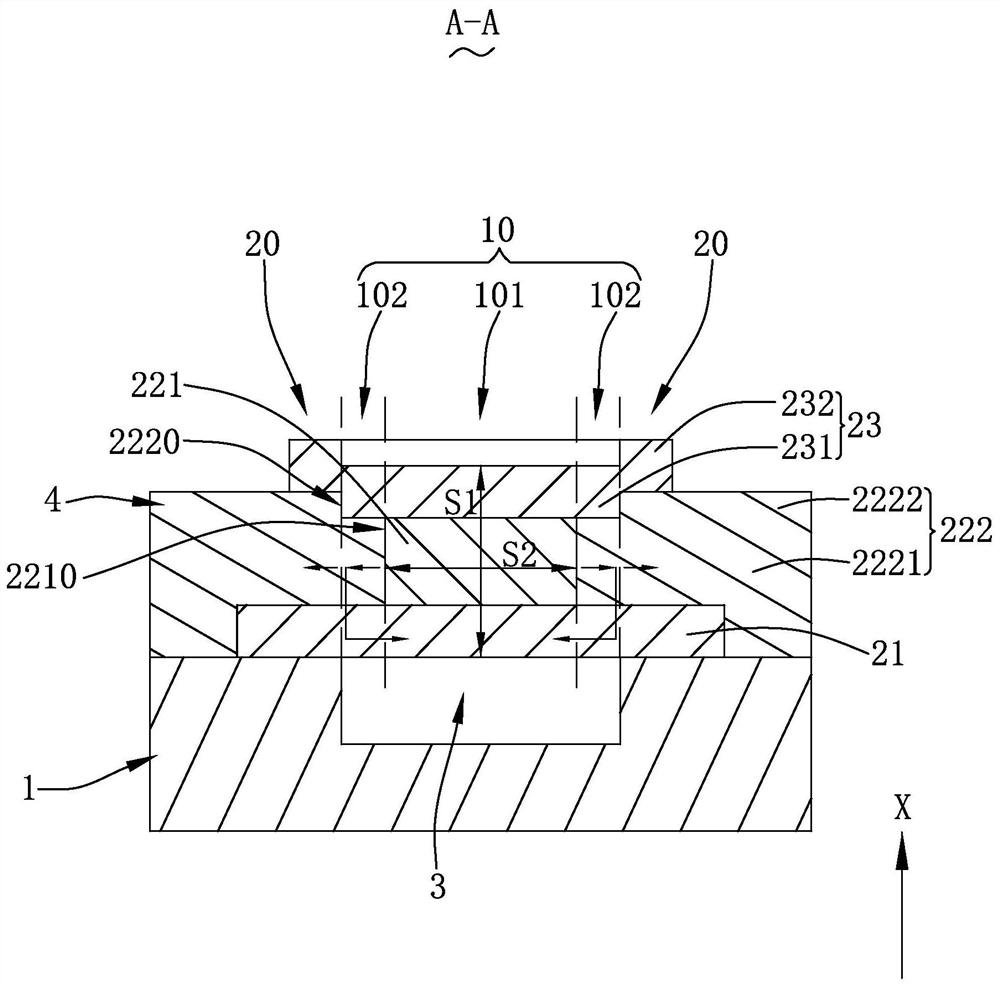

[0028] see Figure 1-3 As shown, the present invention provides a resonator 100, which includes a substrate 1, a composite film 2 arranged above the substrate 1 along a first direction (ie, the X-axis direction), and a composite film 2 arranged between the substrate 1 and the composite film. 2 between the longitudinal acoustic wave reflector 3, wherein the first direction is the thickness direction of the resonator 100.

[0029] The composite film 2 includes a first electrode 21, a piezoelectric functional film 22 and a second electrode 23 arranged in sequence along the first direction, and the first electrode 21 is arranged on the substrate 1 and the longitudinal acoustic wave reflector 3 or more.

[0030] The arrangement of two adjacent structures is not limited. For example, in the first embodiment, the composite film 2 is stacked on the surface of the substrate 1, and the first electrode 21 is stacked on the The base 1 is also covered on the longitudinal acoustic wave re...

Embodiment approach 2

[0047] see Figure 4-5 shows the resonator 100a of Embodiment 2, Figure 4 In essence figure 2 The schematic diagram of another embodiment of the shown structure, the resonator 100a of the second embodiment is a derivative embodiment of the sound-generating device of the first embodiment, the structures of the two are basically the same, and the same parts will not be described one by one, but the embodiment The main differences between the two resonators 100a are:

[0048] The longitudinal acoustic wave reflector 3a is a Bragg acoustic mirror arranged on the side of the substrate 1a close to the first electrode 21a, and the first electrode 21a is arranged on the side of the Bragg acoustic mirror away from the substrate 1a; more specifically, the first electrode 21a is stacked On the surface of the Bragg acoustic reflector far away from the substrate 1a, of course, in other embodiments, it is also feasible that the first electrode and the Bragg acoustic reflector are not di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap