Chemical rectifying kettle and rectifying tower connecting device

A technology for rectification stills and rectification towers, which is applied in the field of combined devices for chemical distillation stills and rectification towers. Stabilizing effect, avoiding damage, avoiding the effect of backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

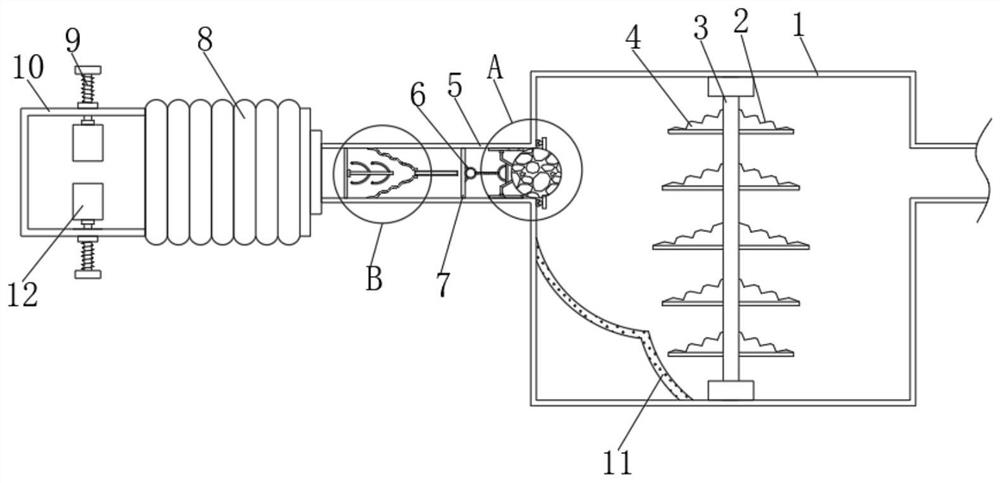

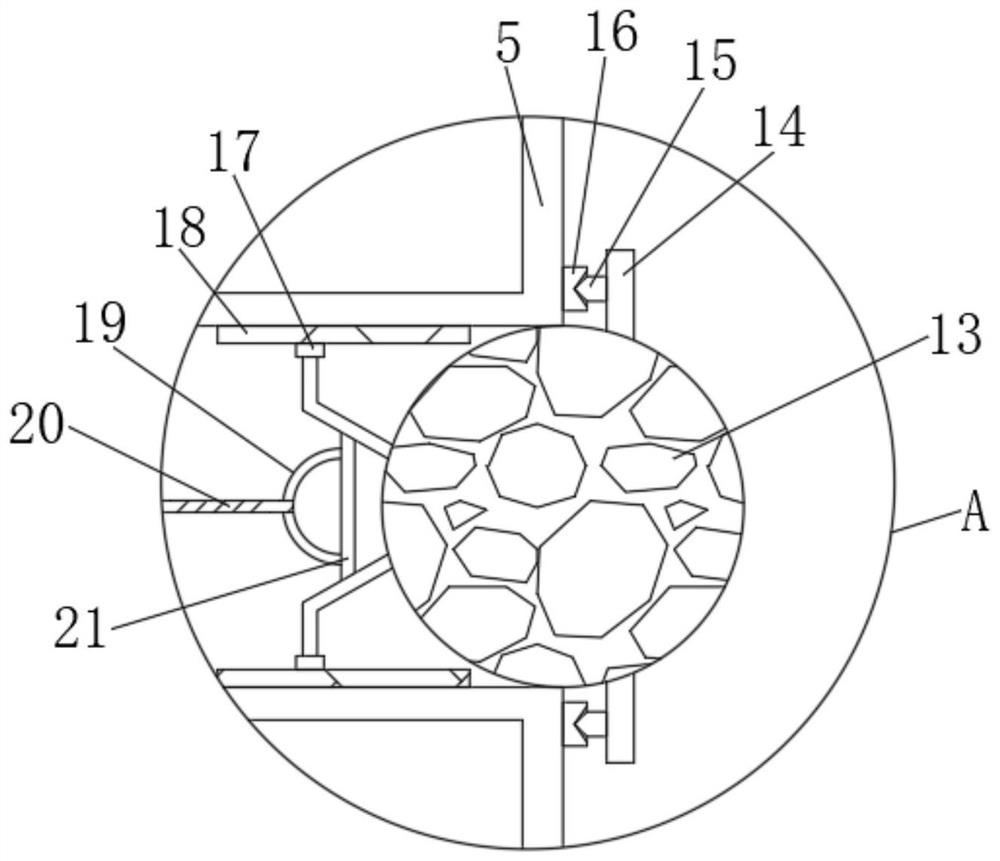

[0028] refer to Figure 1-4 , a chemical distillation kettle and rectification tower connection device, including a surge tank 1, a connecting pipe 5 is plugged into one side of the surge tank 1, and a corrugation is inserted into the end of the connecting pipe 5 away from the surge tank 1 Pipe 8, one end of corrugated pipe 8 is plugged with fixed pipe 10, and the top outer wall of fixed pipe 10 is provided with threaded hole, and the inner thread of threaded hole is connected with fixed screw rod 9, and the outer wall of one end of fixed screw rod 9 is rotatably connected with clamping Ring 12, the top and bottom inner walls of the surge tank 1 are rotatably connected with the first rotating rod 3, and the outer walls on both sides of the first rotating rod 3 are connected with stirring blades 4 by bolts, and one side outer wall of the stirring blade 4 has a Grooves 2 are equidistantly distributed, and the inner walls on both sides of the surge tank 1 are connected with defle...

Embodiment 2

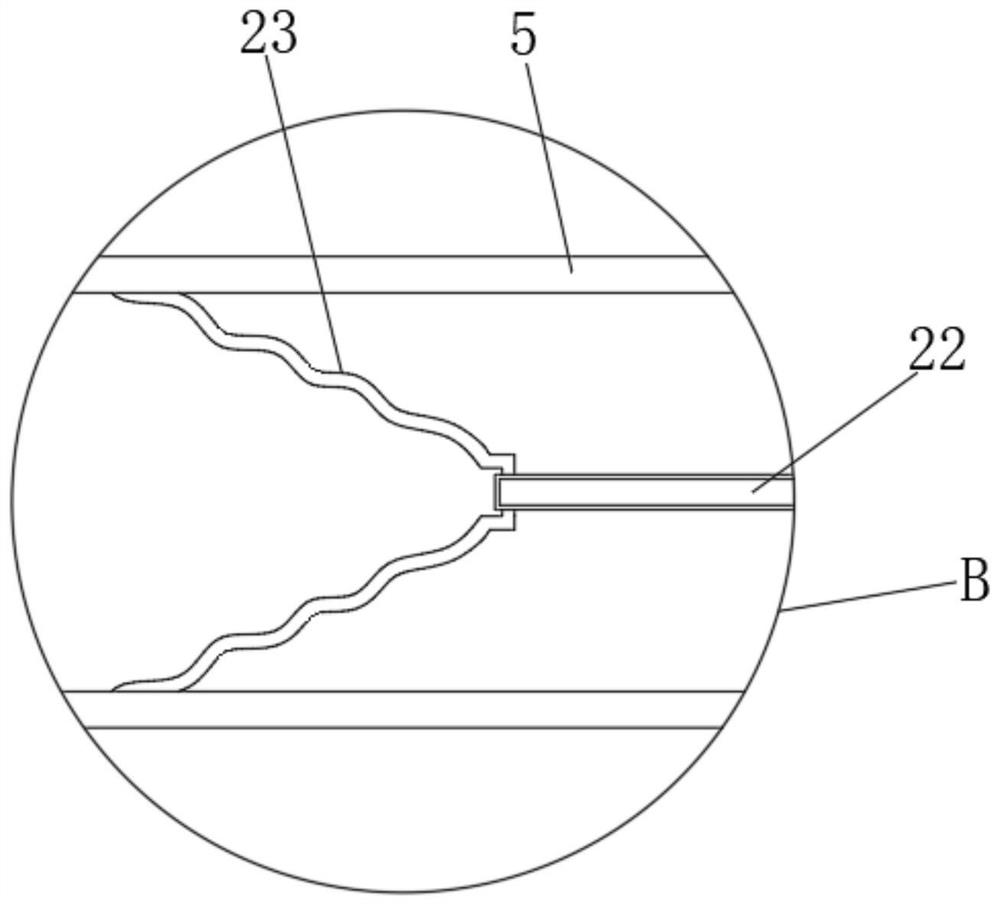

[0032] refer to Figure 5 , a chemical rectification kettle and rectification tower joint device. Compared with embodiment 1, the inner walls of both sides of the connecting pipe 5 are connected with the third connecting rod 26 by bolts in this embodiment, and one part of the third connecting rod 26 The side outer wall is rotatably connected with a second rotating rod 25, and the peripheral outer wall of the second rotating rod 25 is connected with a stirring rod 24 by bolts.

[0033] Working principle: when the water flow flows in the diversion bucket 23, it will drive the second rotating rod 25 and the stirring rod 24 to rotate together, so that the water flow can generate a vortex, making the water flow more rapid, and at the same time, the sealing ball 13 can be easily flushed away .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com