Raw material mixing machine for food processing

A food processing and mixer technology, applied in mixers, mixer accessories, TVs, etc., can solve the problems of consuming a lot of time, unable to break food raw materials, etc., and achieve the effect of fully mixing raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

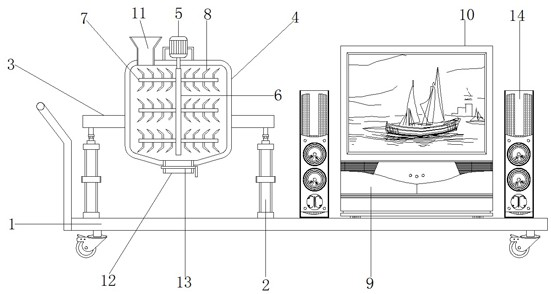

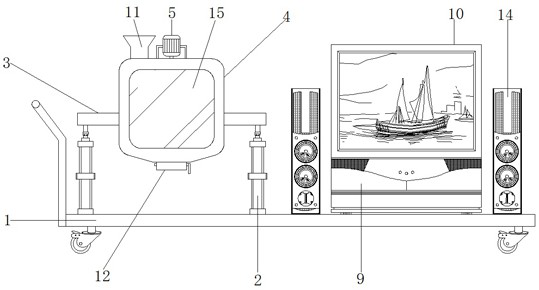

[0018] Embodiment 1, with reference to Figure 1-2 , a raw material mixer for food processing, comprising a bottom plate 1, four equidistantly distributed cylinders 2 are arranged at one end of the top of the bottom plate 1, and the piston rods of the four cylinders 2 are fixedly connected with the same mounting plate 3, and the top of the mounting plate 3 A mixing tank 4 is embedded in the central position, and the outer wall of one side of the mixing tank 4 has an installation opening, and a transparent observation window 15 is installed in the installation opening, and a feeding hopper 11 is welded on one side of the inner wall of the top of the mixing tank 4, and the bottom of the mixing tank 4 A feeding pipe 12 is welded on the inner wall, and a baffle 13 is plugged into the outer wall of one side of the feeding pipe 12, and the cross section of the baffle 13 is larger than the cross section of the inner wall of the feeding pipe 12, and the center position of the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com