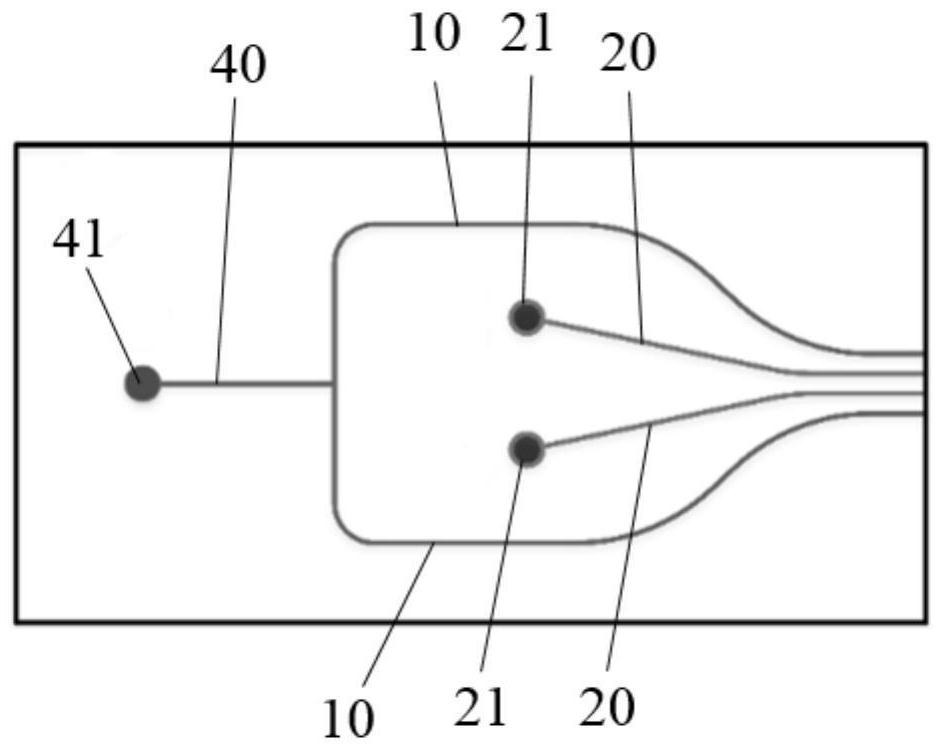

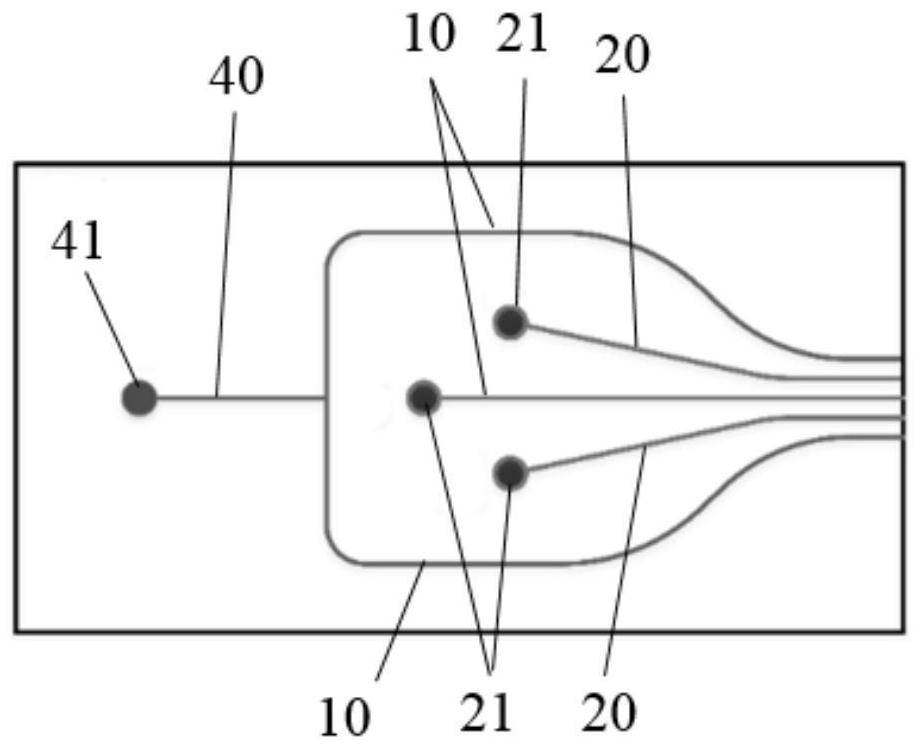

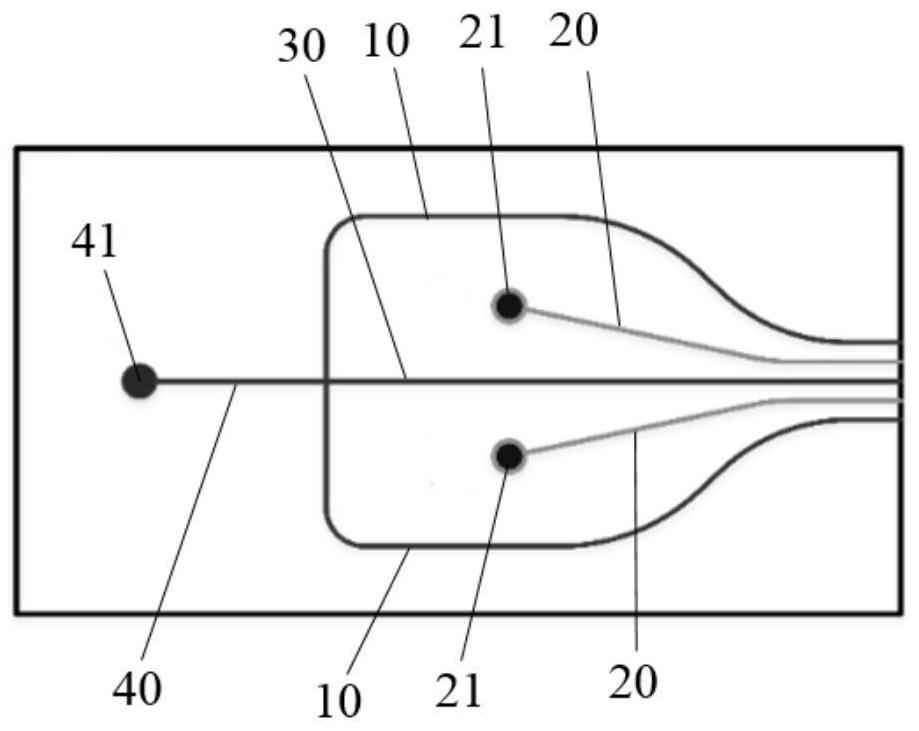

Multichannel electrospray micro-fluidic chip and application thereof

A microfluidic chip and electrospray technology, which is used in material analysis by electromagnetic means, laboratory containers, measuring devices, etc., can solve the problems of poor experimental operability and reproducibility, poor ionization effect and weak test signal. and other problems, to achieve the effect of rapid detection, improvement of extraction efficiency and extraction effect, and stable and consistent spray conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention provides a multi-channel electrospray microfluidic chip and its application. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0032] In the process of mass spectrometry, the extraction and ionization effects of the liquid to be tested have a great influence on the test results of mass spectrometry, but because the relative positions of the two independent nozzles of the macroscopic electrospray extraction ionization (EESI) device are not fixed, so Before the experiment, it is necessary to adjust the relative positions of the two independent nozzles. Such an operation often reduces the operability and reproducibility of the experiment, and the extraction efficiency of the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com