High temperature resistant precoated sand

A technology of coated sand and high temperature resistance, applied in the field of coated sand, can solve problems such as the inability to meet the requirements of precision casting, and achieve the effects of long heat resistance time and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

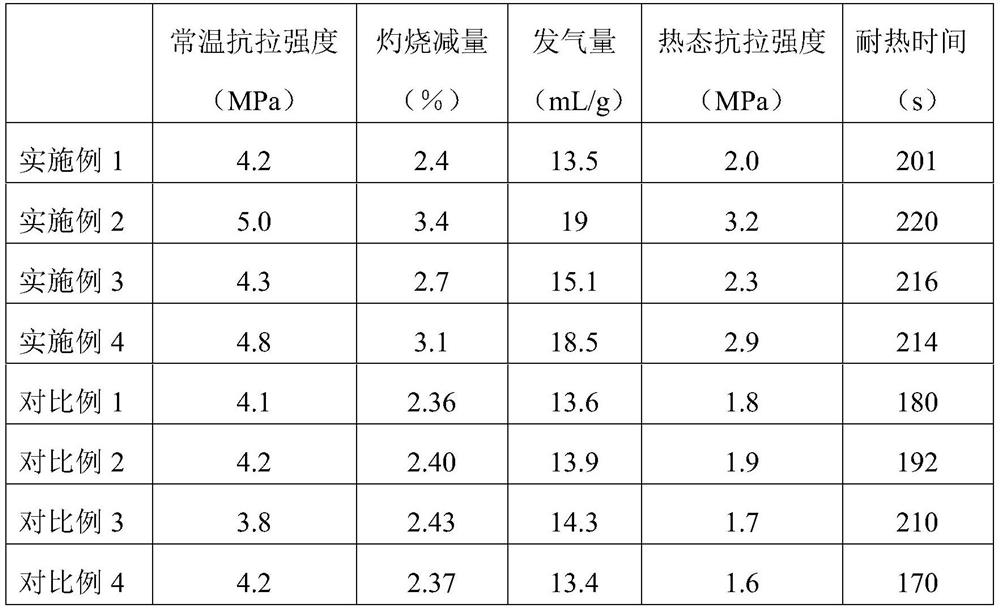

Examples

Embodiment 1

[0025] Weigh 100kg of silica sand, 2kg of thermoplastic phenolic resin, 0.2kg of carbon fiber, 0.2kg of urotropine, and 0.15kg of calcium hardate, wherein the particle size of the carbon fiber is 270 mesh.

[0026] (1) Heat the silica sand to 150°C and put it into the sand mixer;

[0027] (2) Add phenolic resin into the sand mixer and stir for 40 seconds to completely melt the thermoplastic phenolic resin;

[0028] (3) Add carbon fiber into the sand mixer and stir for 20s to mix the carbon fiber and resin evenly;

[0029] (4) Add curing agent and water into the sand mixer, cool down rapidly, and stir for 40 seconds to completely cure the resin;

[0030] (5) Add lubricant into the sand mixer and stir for 30s to make the coated sand into granules;

[0031] (6) Crushing and screening to obtain high temperature resistant coated sand.

Embodiment 2

[0033] Weigh 100kg of silica sand, 3kg of thermoplastic phenolic resin, 0.3kg of carbon fiber, 0.4kg of urotropine, and 0.2kg of calcium hardate, wherein the particle size of the carbon fiber is 200 mesh.

[0034] (1) Heat the silica sand to 140°C and put it into the sand mixer;

[0035] (2) Add phenolic resin into the sand mixer and stir for 30s to completely melt the thermoplastic phenolic resin;

[0036] (3) Add carbon fiber into the sand mixer and stir for 15 seconds to mix the carbon fiber and resin evenly;

[0037] (4) Add curing agent and water into the sand mixer, cool down rapidly, and stir for 50 seconds to completely cure the phenolic resin;

[0038] (5) Add lubricant into the sand mixer and stir for 40s to make the coated sand into granules;

[0039] (6) Crushing and screening to obtain high temperature resistant coated sand.

Embodiment 3

[0041] Weigh 100kg of silica sand, 2.2kg of thermoplastic phenolic resin, 0.4kg of carbon fiber, 0.5kg of urotropine, and 0.25kg of calcium hardate, wherein the particle size of the carbon fiber is 230 mesh.

[0042] (1) Heat the silica sand to 130°C and put it into the sand mixer;

[0043] (2) Add phenolic resin into the sand mixer and stir for 30s to completely melt the thermoplastic phenolic resin;

[0044] (3) Add carbon fiber into the sand mixer and stir for 15 seconds to mix the carbon fiber and resin evenly;

[0045] (4) Add curing agent and water into the sand mixer, cool down rapidly, and stir for 50s;

[0046] (5) Add lubricant into the sand mixer and stir for 40s to make the coated sand into granules;

[0047] (6) Crushing and screening to obtain high temperature resistant coated sand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com